Intelligent track correction system and method in finishing machining

A trajectory and intelligent technology, which is applied in the field of trajectory intelligent correction system in finishing, can solve the problems of deviation of processing trajectory, non-compliance with processing requirements, and decreased processing accuracy, so as to improve processing efficiency, improve processing quality rate, and control simple and reliable. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

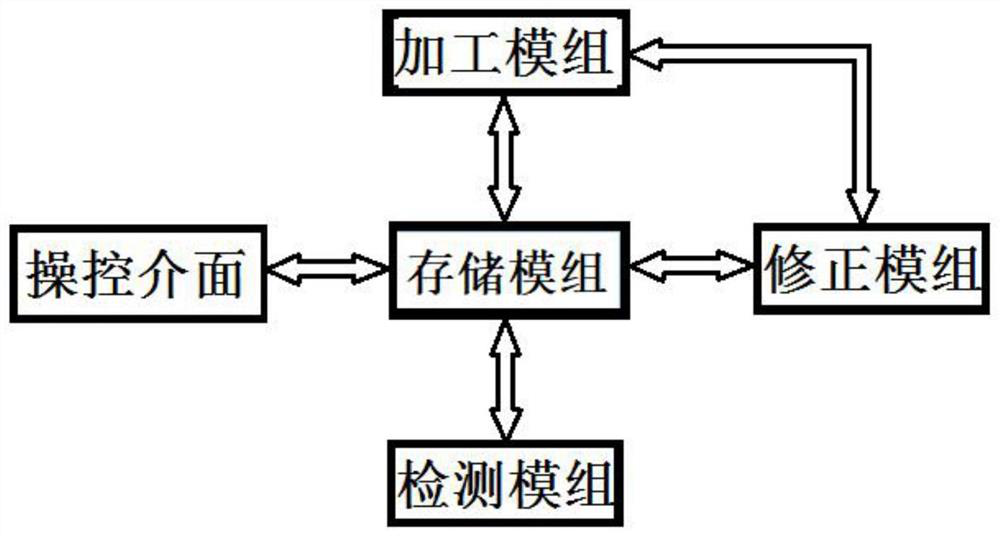

[0027] see figure 1 , shows the smart trajectory correction system in finishing machining of the present invention.

[0028] The trajectory intelligent correction system in finishing machining at least includes a control interface, a detection module, a correction module, a processing module, and a storage module, and the storage module is connected to the control interface, the detection module, the correction module, and the processing module. group, the correction module is connected to the processing module.

[0029] Wherein, the control interface provides an input channel for the operator, and can also provide a channel for the operator to query information such as control data in the correction system. Therefore, the control interface can be a touch-type control interface or a display The assembly of the screen and the control keyboard, so that the operator can set the machining trajectory of the tool during the machining of the workpiece through the control interface, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com