Special drilling machine for two-piece tire mold

A technology for tire molds and drilling machines, which is applied in the direction of manufacturing tools, boring/drilling, drilling/drilling equipment, etc. It can solve the problems that it is difficult to guarantee the layer depth and arc processing requirements, and achieve simple structure, reduce production costs, The effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

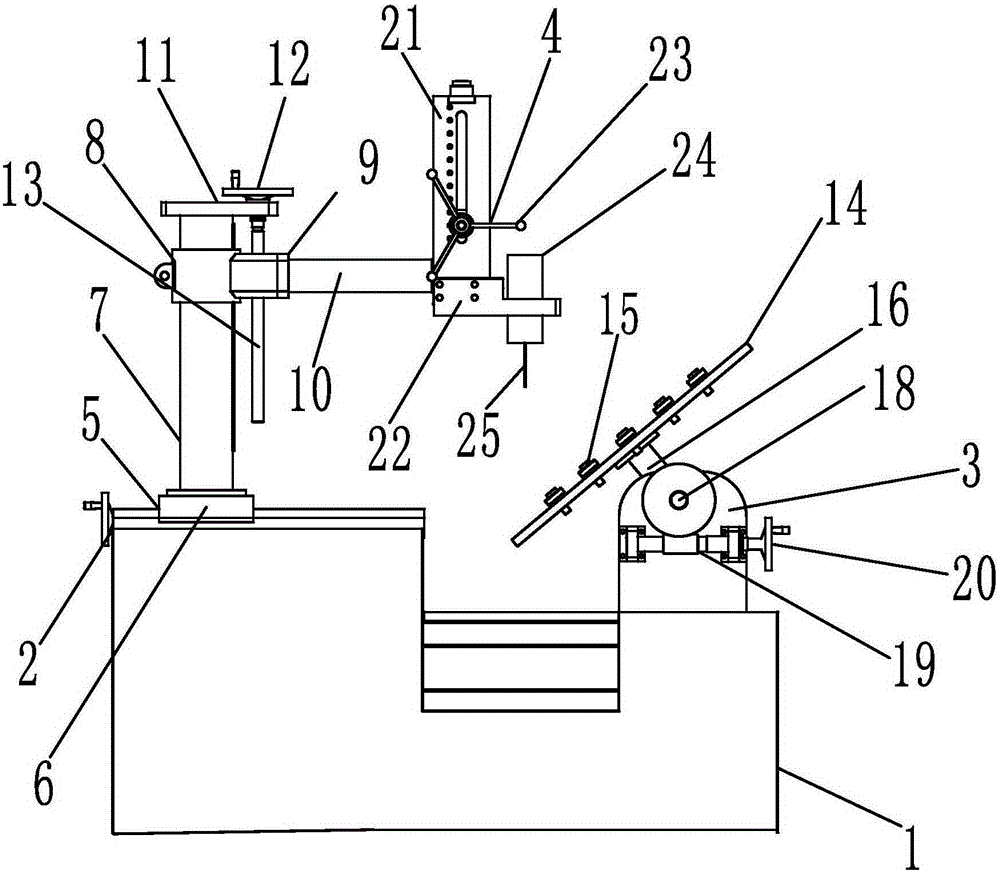

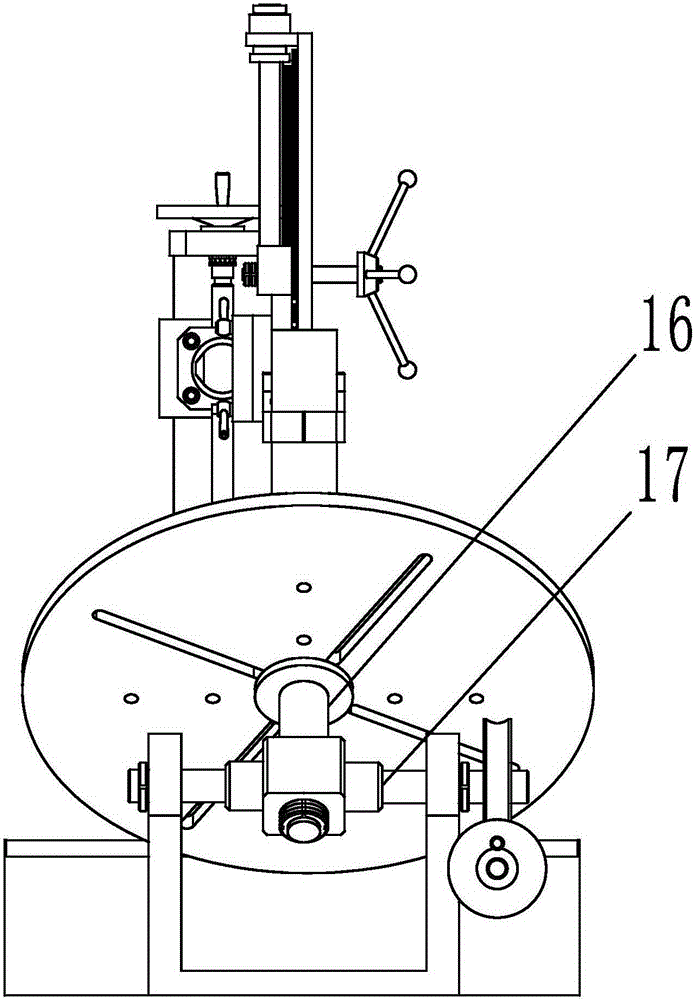

[0012] Such as figure 1 , 2 As shown, the technical solution adopted by the present invention is: a special drilling machine for tire molds with two halves, including a base 1, a guide rail system 2, a rotary table system 3 and a spindle system 4, and the guide rail system is installed on the upper left end of the base 1 2. The rotary table system 3 is located at the upper right end of the base 1, and its height is lower than the guide rail system 2, and the spindle system 4 is installed on the guide rail system 2.

[0013] The bottom end of the guide rail system 2 is provided with a guide rail 5 installed on the base 1, a slide plate 6 is arranged inside the guide rail 5, a column 7 is fixed on the slide plate 6, and a clamping mechanism is provided at a position near the top of the column 7 8. A lifting sleeve 9 is installed on the right end of the clamping mechanism 8, a beam 10 is installed on the lifting sleeve 9, a lifting screw handwheel fixing device 11 is installed o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com