Nitrogen-doped mesoporous carbon supported alloy nano-catalyst and application thereof

A nitrogen-doped mesoporous carbon, nano-alloy technology, applied in physical/chemical process catalysts, heterocyclic compound preparation, organic chemistry, etc., can solve the problems of reducing product selectivity, reducing life, etc. Highly selective, highly selective effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

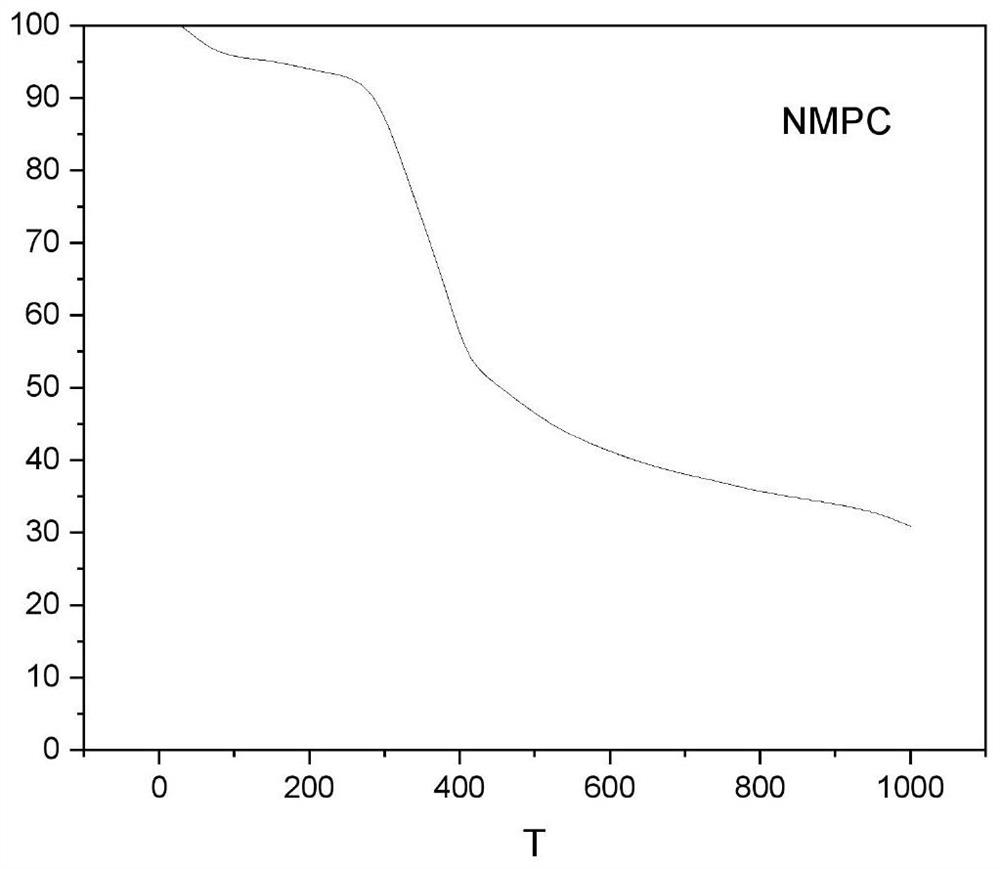

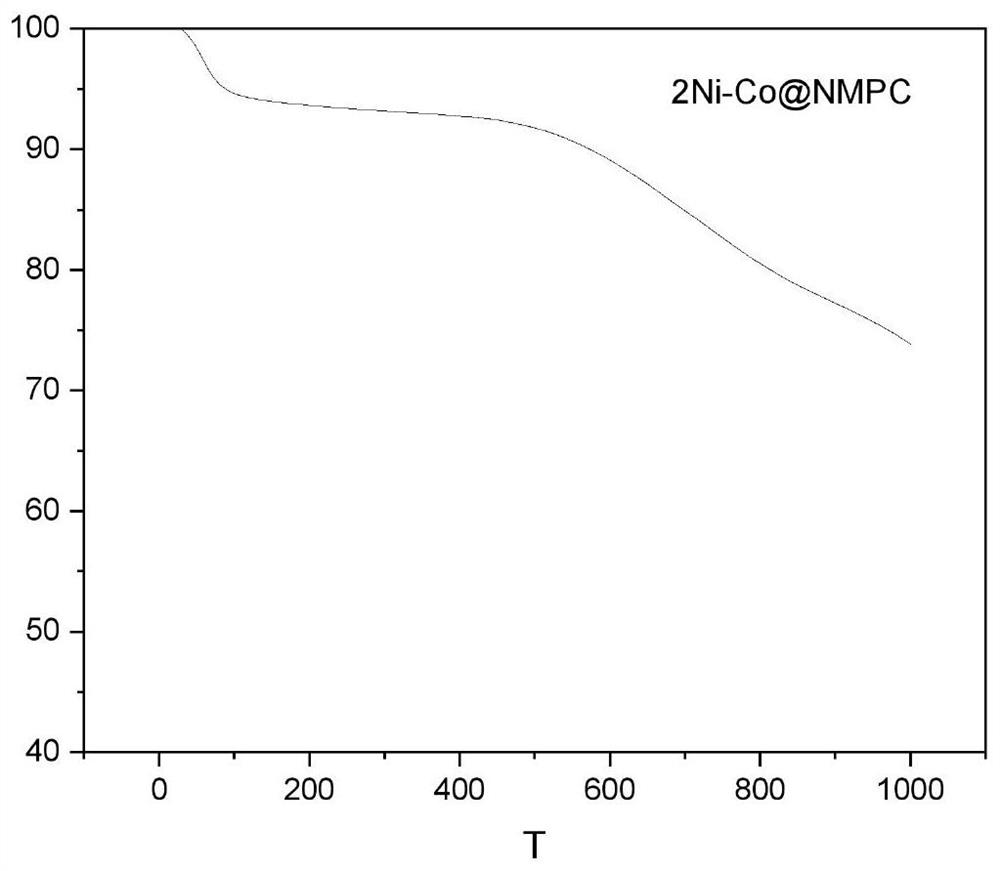

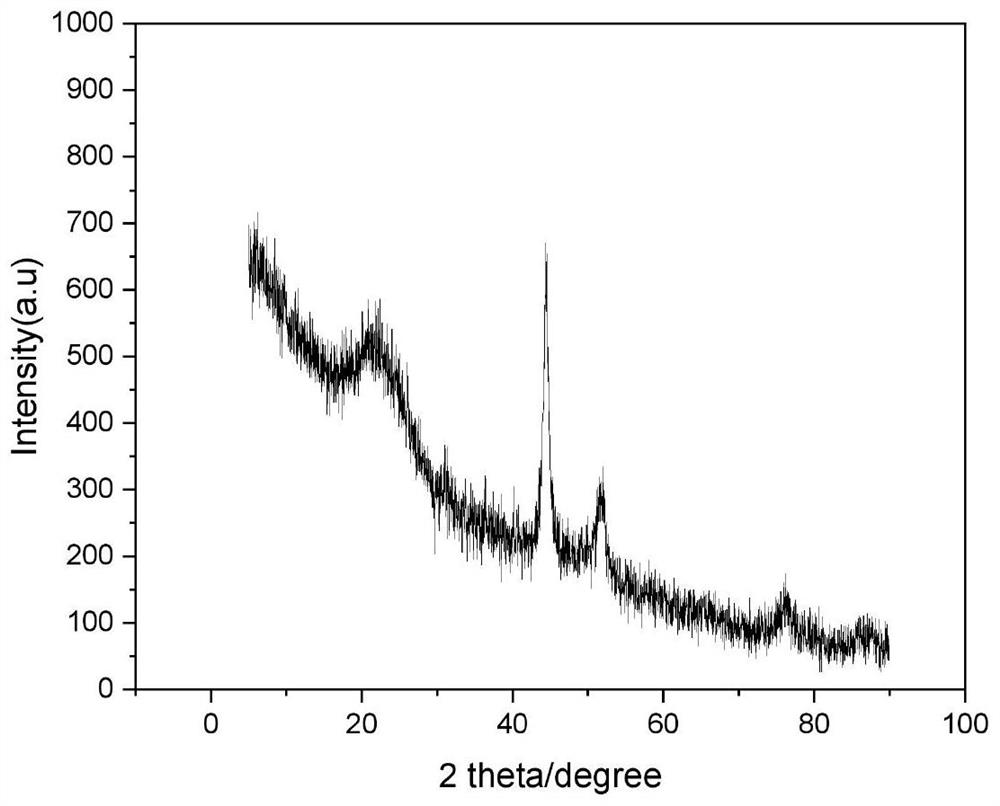

[0054] The present embodiment provides a method for preparing a 2Ni-Co@NMPC catalyst by an impregnation method, and its performance of catalyzing furfural to prepare cyclopentanone is tested, as follows:

[0055] (1) Preparation of catalyst:

[0056] 2.2g of resorcinol, 0.46g of urotropine and 30ml of deionized water were stirred at 40°C for 1 hour, and another 0.42g of melamine, 0.23g of urotropine and 20ml of deionized water were taken and stirred at 80°C until the solution was After clarification, F1270.306g was added until dissolved. After mixing the above two solutions, after reacting at 80 °C for 24 hours, a precipitate formed. After stopping the reaction, the reaction mixture was filtered, and the separated solid was fully washed with ethanol and water, vacuum dried at 80 °C, and the solid was ground and sieved. , to obtain a NMPC precursor with uniform particle size, and the precursor was NMPC in a tube furnace. 2 The NMPC carrier was prepared by annealing at 550 °C ...

Embodiment 2

[0068] The present embodiment provides a method for preparing a 2Ni-Co@NMPC catalyst by an impregnation method, and its performance of catalyzing furfural to prepare cyclopentanone is tested, as follows:

[0069] (1) Preparation of catalyst:

[0070] Follow the steps and conditions of Example 1.

[0071] (2) Catalytic furfural to prepare cyclopentanone

[0072] 0.8g of catalyst prepared above, 5.0g of furfural and 25ml of deionized water were weighed into the autoclave, and N 2 After replacing the autoclave air for 5 times, H 2 Replace the reactor for 2 times, and finally feed 4.5MPa H 2 , seal the reactor. Turn on the autoclave to stir, heat the autoclave until the autoclave temperature reaches 200 °C, stop heating and stirring after 4 hours of reaction, until the autoclave temperature drops to room temperature, open the autoclave valve, and safely discharge the remaining H 2. Add 25 ml of absolute ethanol to the reaction mixture in the autoclave, and after mixing evenl...

Embodiment 3

[0075] The present embodiment provides a method for preparing a 2Ni-Co@NMPC catalyst by an impregnation method, and its performance of catalyzing furfural to prepare cyclopentanone is tested, as follows:

[0076] (1) Preparation of catalyst:

[0077] Follow the steps and conditions of Example 1.

[0078] (2) Catalytic furfural to prepare cyclopentanone

[0079] After experimenting according to the steps and conditions of Example 1, the catalyst and the reaction solution were separated by centrifugation. The catalyst obtained by centrifugation was washed with ethanol for 5 times and then placed in an oven for drying. No other treatment was required. The furfural hydrogenation experiment was carried out at the bottom of the experiment, and the cycle was repeated 5 times. After detection by gas chromatography internal standard method, the conversion rates of furfural were all higher than 90%, and the selectivity of cyclopentanone reached 80%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com