Forklift connector combined welding device

A connecting piece and combined welding technology, which is applied in the direction of auxiliary equipment, welding equipment, auxiliary welding equipment, etc., can solve the problems of inability to cooperate with automatic equipment and reduce production efficiency, and achieve the effect of high degree of automation, exquisite structure and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

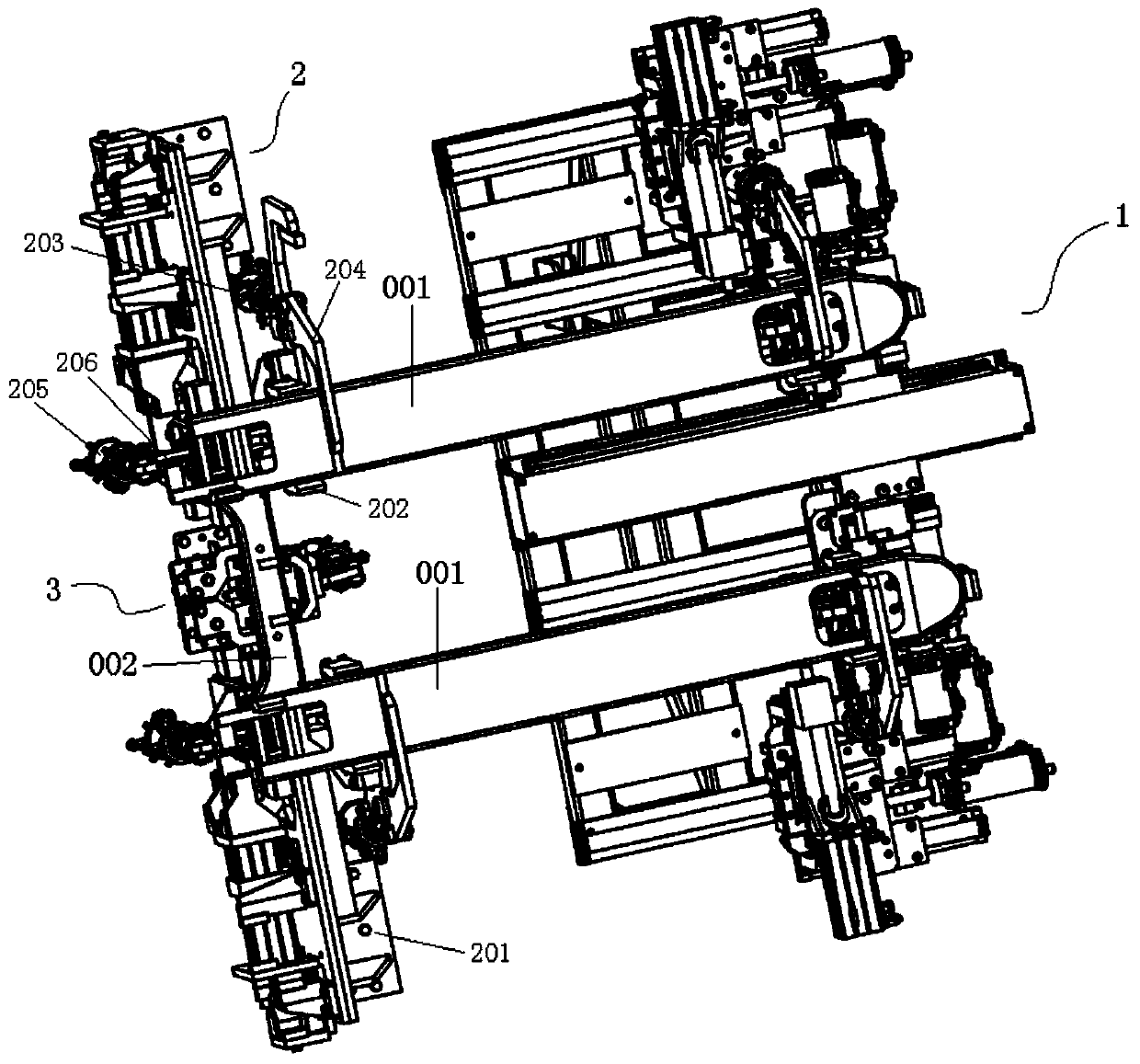

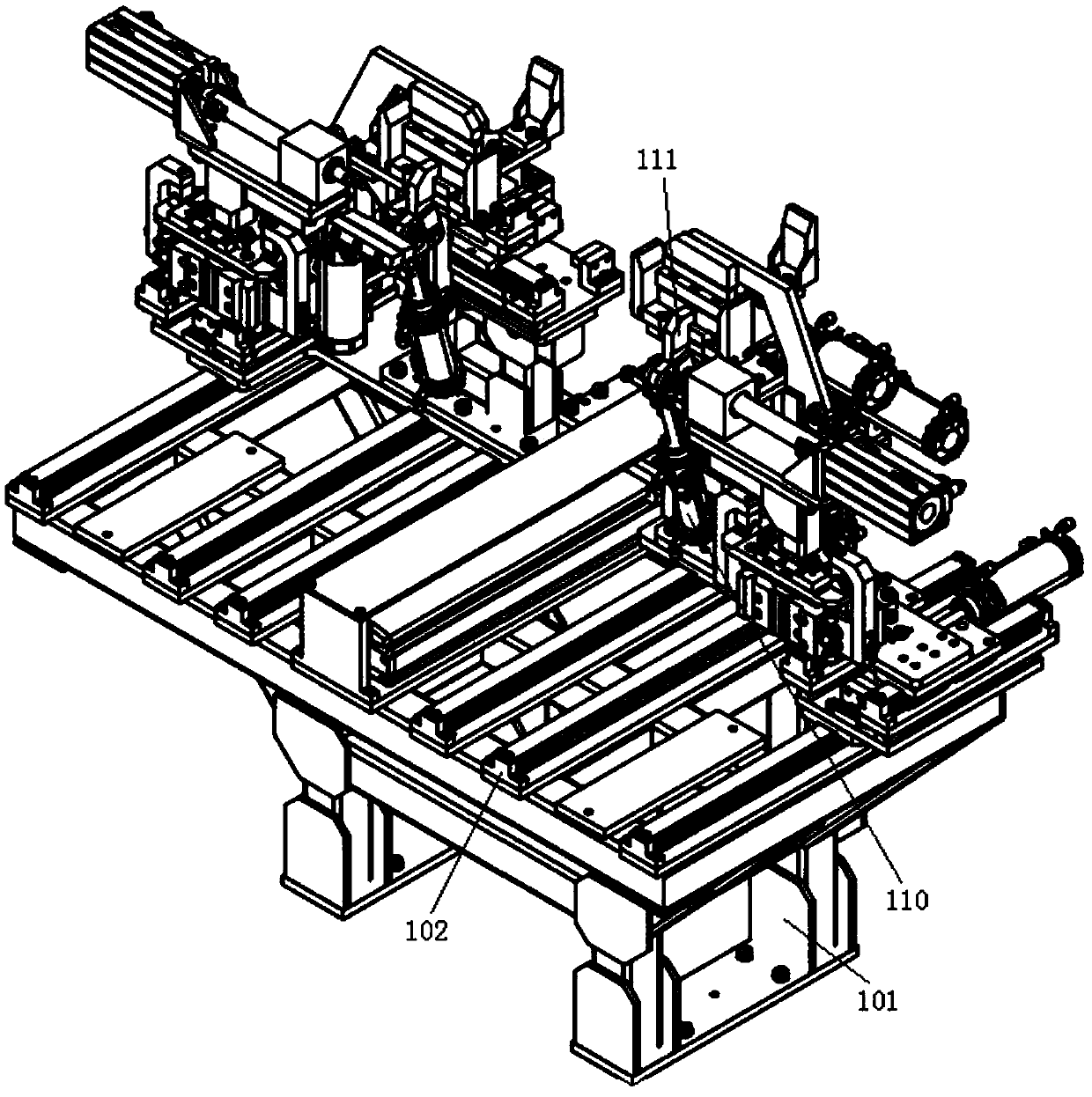

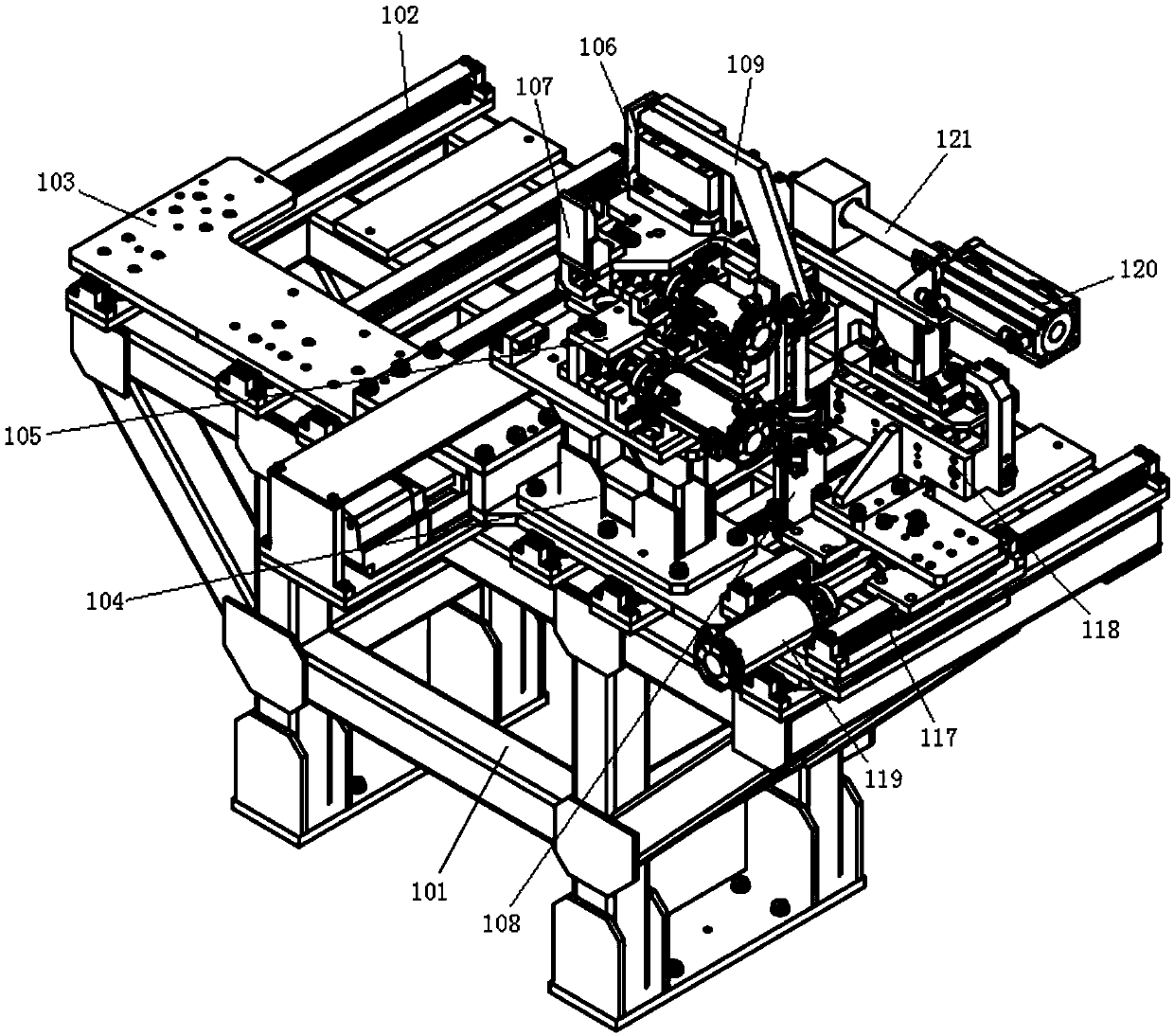

[0026] When in use, the mechanical arm places the two forks 001 between the first U-shaped holder and the second U-shaped holder, the U-shaped holders respectively fix the two sides of the fork, and the first fixed When the cylinder works, the first rotating fixed arm rotates and presses down on the top surface of the fork, the second fixed cylinder works, the second rotating fixed arm rotates and tilts forward and presses on the vertical surface of the bottom surface of the fork, and the top of the fork passes through the stopper Fixed; the third fixed cylinder at the rear end of the fork works, the third rotating fixed arm rotates and presses down on the top surface of the fork, the fourth fixed cylinder works, the fourth rotating fixed arm rotates forward and presses on the end of the fork; the fork After the fixation is completed, the mechanical arm places the connecting piece 002 on the bottom support piece, the ascending cylinder works to raise the connecting piece to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com