Paint spraying device

A one-to-one, component technology, applied in the direction of spraying devices, spray booths, etc., can solve the problems of simultaneous painting of multiple metal pipe fittings, low painting efficiency, and unfavorable production needs of enterprises, so as to achieve high market application value and improve painting efficiency , easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

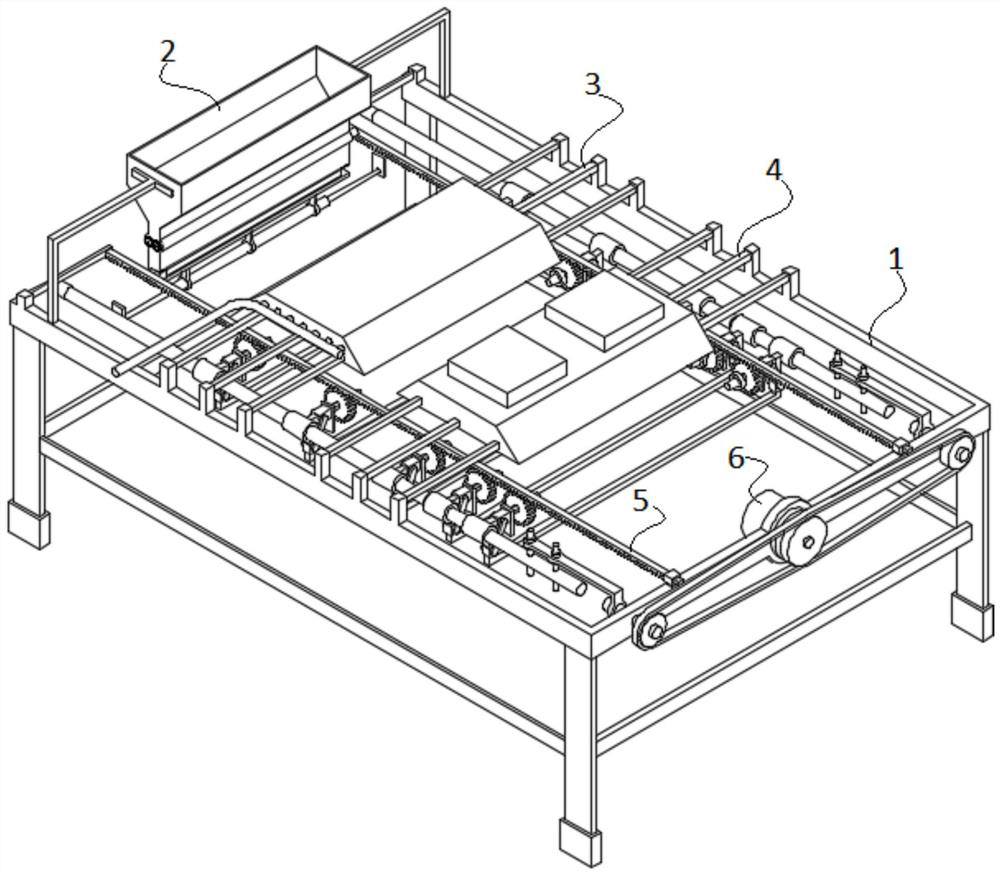

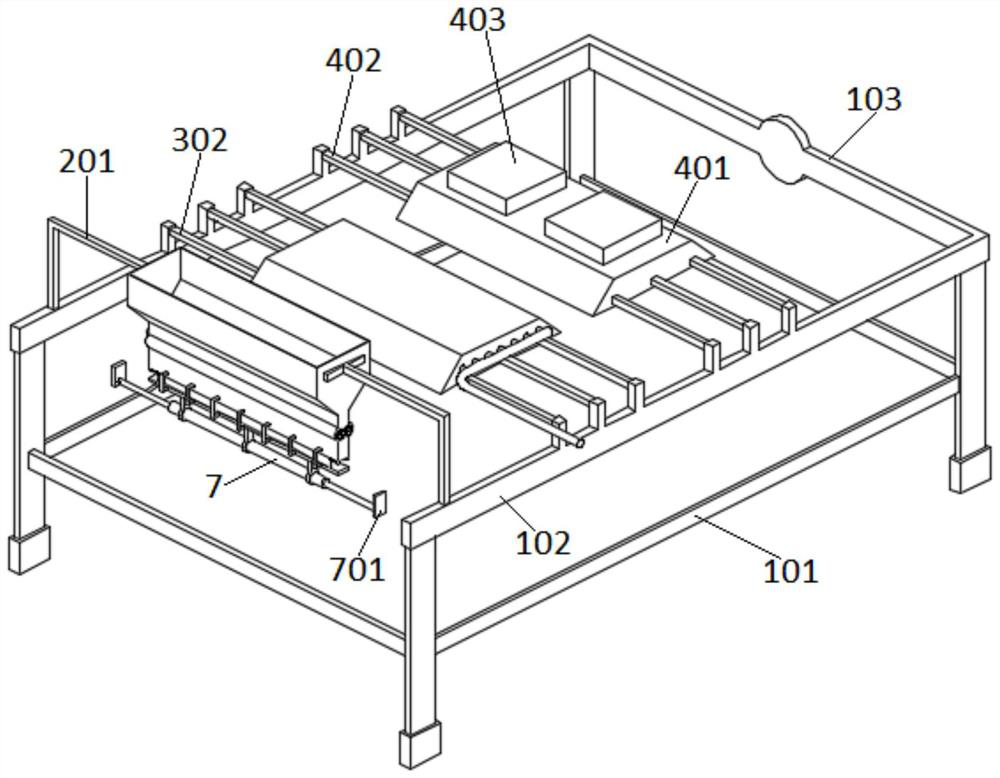

[0033] see Figure 1-Figure 4 As shown, the present invention is a painting device, including a support assembly 1; the support assembly 1 includes a support frame 101; a pair of side support beams 102 are horizontally fixed on the support frame 101; The beams 103 are connected; between the supporting beams 102 on both sides, a feeding assembly 2, a painting assembly 3 and a drying assembly 4 are arranged side by side along the length direction; the drying assembly 4 is arranged between the painting assembly 3 and the middle beam 103; The beam 103 is equipped with a transport assembly 5 . The material is taken from the feeding assembly 2 through the conveying assembly 5, and then the material is carried by the feeding assembly 2 through the painting assembly 3 and the drying assembly 4 to realize painting and drying.

specific Embodiment 2

[0035] This embodiment is further optimized on the basis of specific embodiment one, specifically as follows:

[0036] Such as image 3 and Figure 5-Figure 7As shown, the feeding assembly 2 includes a pair of first support rods 201 respectively fixed on the support beams 102 on both sides; a storage box 202 is fixed between the two first support rods 201; the upper part of the storage box 202 is open Structure; the bottom of the material storage box 202 has a sliding material channel 2021; the external expansion chamber 2022 is provided in the material sliding channel 2021; a pair of drive shafts 203 are installed in the external expansion chamber 2022 along the length direction; the outer wall of the drive shaft 203 There are a plurality of paddles 2031 fixed in the radial direction; two drive shafts 203 are fixed with rotating gears 2032 toward the same end; One end of one end is connected on the output shaft of a rotating motor 2033; The rotating motor 2033 is fixed on t...

specific Embodiment 3

[0040] This embodiment is further optimized on the basis of specific embodiment two, specifically as follows:

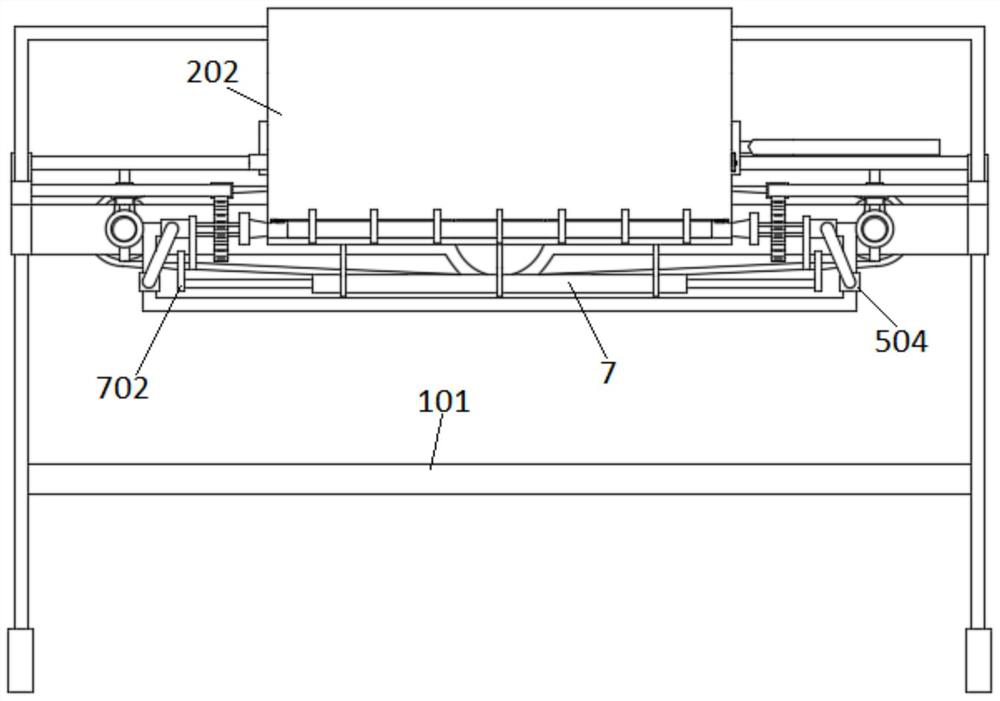

[0041] Such as Figure 4 and Figure 9-Figure 10 As shown, the transport assembly 5 includes a pair of guide racks 501 arranged side by side between the support beams 102 on both sides; A pair of drive screw mandrels 502 are installed for rotation between the bars 501; the drive screw mandrels 502 are arranged in parallel with the guide rack 501; the drive screw mandrels 502 are sleeved with a plurality of screw nuts 5021 side by side; Corresponding two nuts 5021 are connected by a bearing rod 503; the bearing rod 503 includes a pair of horizontal guide sections 5031 respectively fixed on the outer walls of the two nuts 5021; set vertically; the ends of the two horizontal guide sections 5031 are fixed with a vertical guide section 5032; the lower ends of the two vertical guide sections 5032 are connected by a connecting section 5033; the horizontal guide section 50...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com