Synchronously and uniformly automated painting device for inner and outer walls of tubular member

A technology for inner and outer walls and tubular parts, which is applied in the field of synchronous and uniform automatic paint spraying devices for the inner and outer walls of tubular parts, which can solve problems such as difficult and efficient uniform painting of three-dimensional structures, and achieve the effects of novel design, strong practicability, and improved painting quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

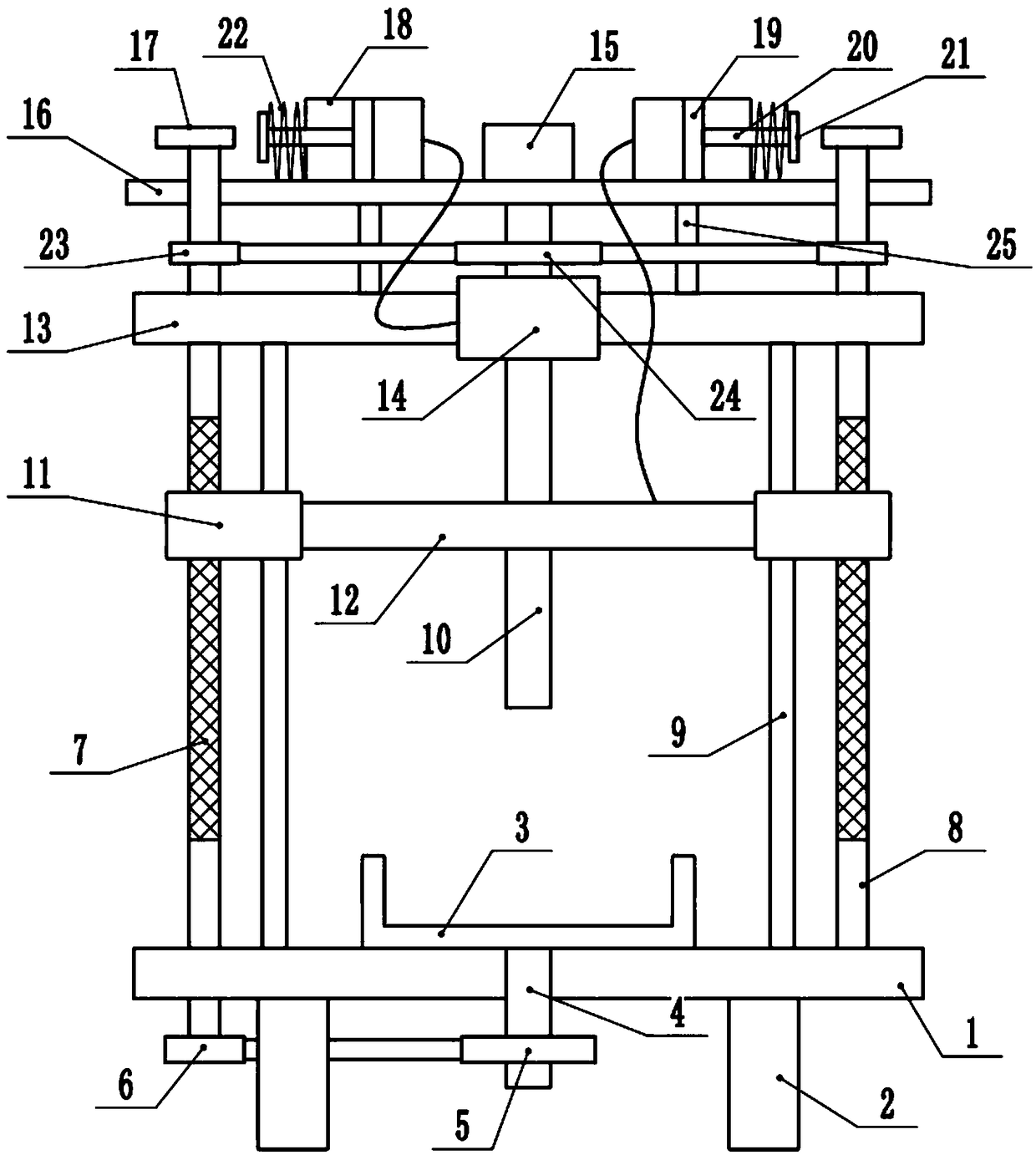

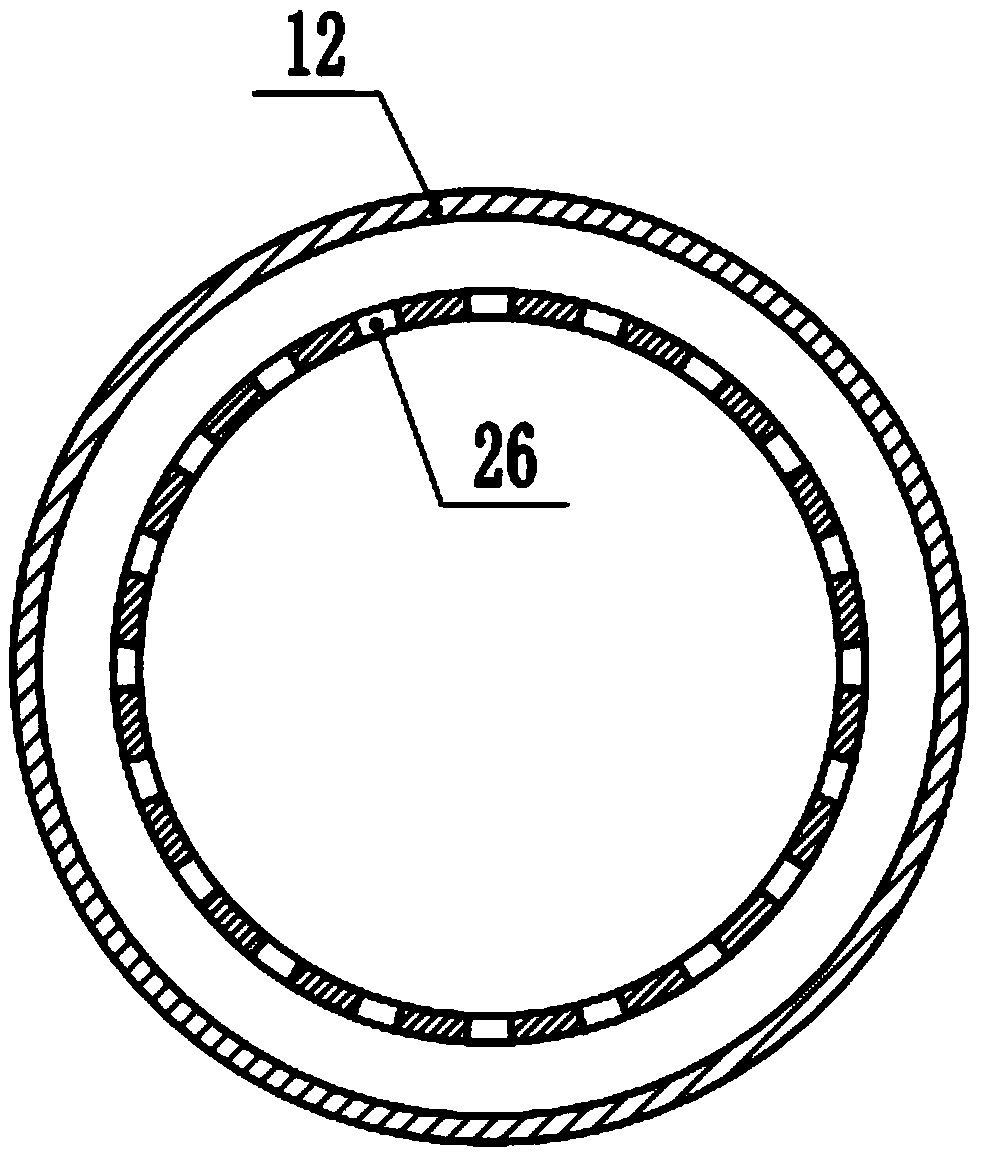

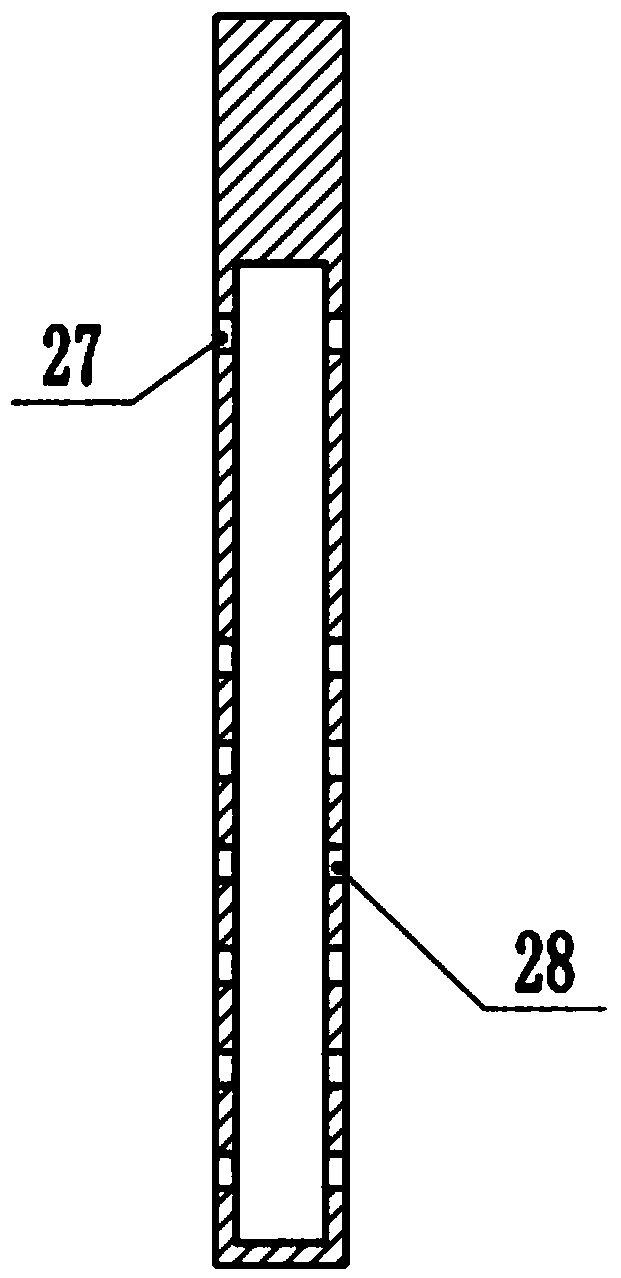

[0030] refer to figure 1 , in an embodiment of the present invention, a synchronous and uniform automatic painting device for the inner and outer walls of a tubular member, including a fixed base 1, and support legs 2 are installed on both sides of the lower end of the fixed base 1, for realizing the support and fixation of the entire device, the fixed base 1 Guide frames 9 are installed on both sides of the upper end of the base 1, which are used to support and limit the top plate 13 and the fixed base 1, and also guide the up and down movement of the reciprocating block 11 to prevent the reciprocating block 11 from shaking during the up and down movement , the upper end of the guide frame 9 is equipped with a top plate 13, the middle part of the top plate 13 is equipped with a paint inlet box 14, the upper end of the top plate 13 is connected with a fixed plate 16 through the top frame 25, and the middle part of the upper end of the fixed plate 16 is equipped with a rotating ...

Embodiment 2

[0035] refer to Figure 4 , in another embodiment of the present invention, the difference between this embodiment and the above-mentioned embodiment is that a clamping rod 30 is installed in the middle of the outer wall of the drive table 3, an adjustment block 29 is installed on the outside of the clamping rod 30, and the clamping rod Clamping ring 31 is installed on the inner side of 30, and by being provided with clamping rod 30, adjusting block 29 and clamping ring 31 in the middle part of driving table 3, the tubular parts that need to be painted can be better fixed to avoid large Range of shaking, to ensure the effect of painting.

[0036] In the present invention, when working, the tubular member is clamped and fixed by the clamping rod 30, the adjusting block 29 and the clamping ring 31 on the driving table 3, and then the rotating motor 15 is started, and the rotating motor 15 drives the rotating shaft 10 to rotate, and On the one hand, through the synchronous rotat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com