Paint spraying device for wood processing

A wood and paint spraying tube technology, applied in the field of wood processing, can solve the problems of insufficient comprehensiveness, low painting efficiency, and insufficiently uniform painting, so as to achieve the effect of uniform painting processing and improving painting efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

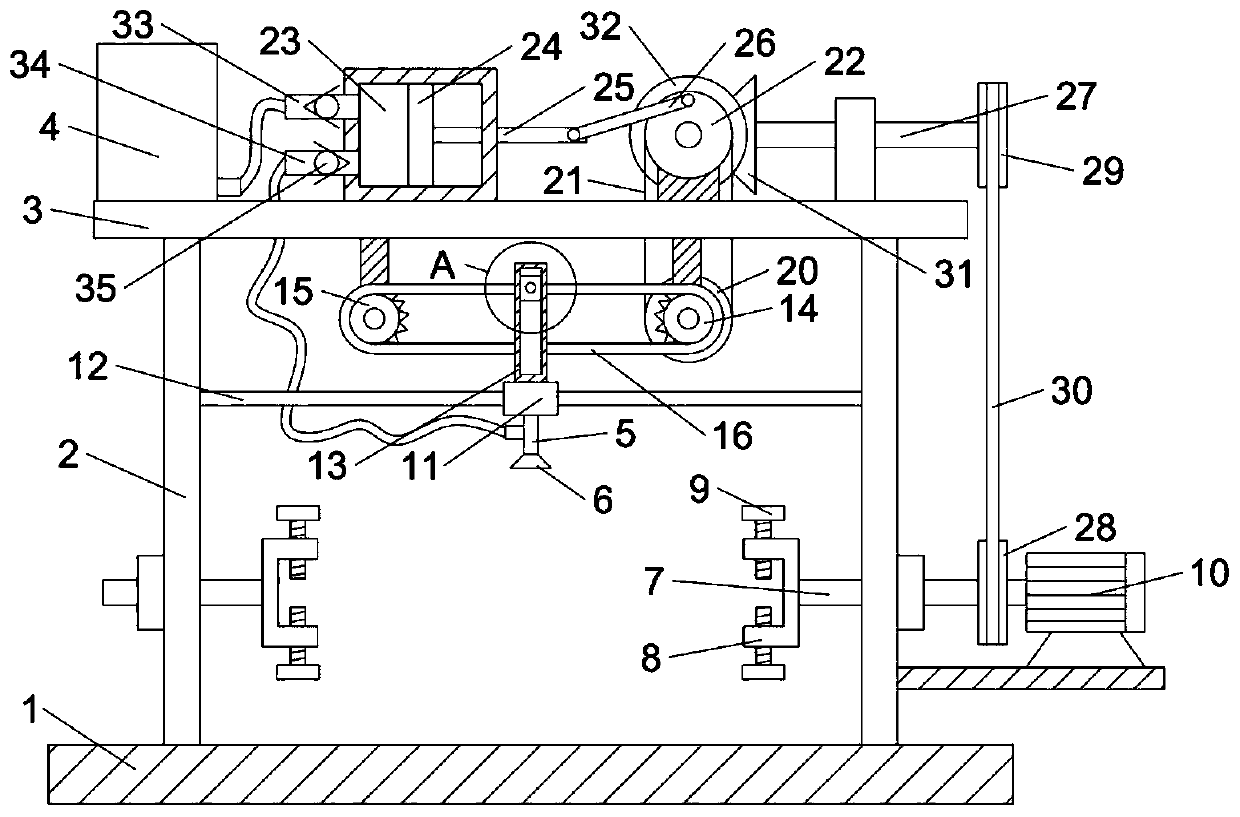

[0025] Please refer to the attached Figure 1-3 , this embodiment provides a paint spraying device for wood processing, including a paint spray pipe 5, the bottom of the paint spray pipe 5 communicates with an atomizing nozzle 6, and the paint spray pipe 5 is connected to the paint storage box 4 through a paint delivery chamber 23 Generally speaking, the described paint storage box 4 and the paint delivery chamber 23 are installed on the top plate 3, and the described top plate 3 is fixedly installed on the top of the base 1 through two groups of brackets 2; The paint in the paint storage box 4 is transported to the paint conveying assembly in the paint spray pipe 5 .

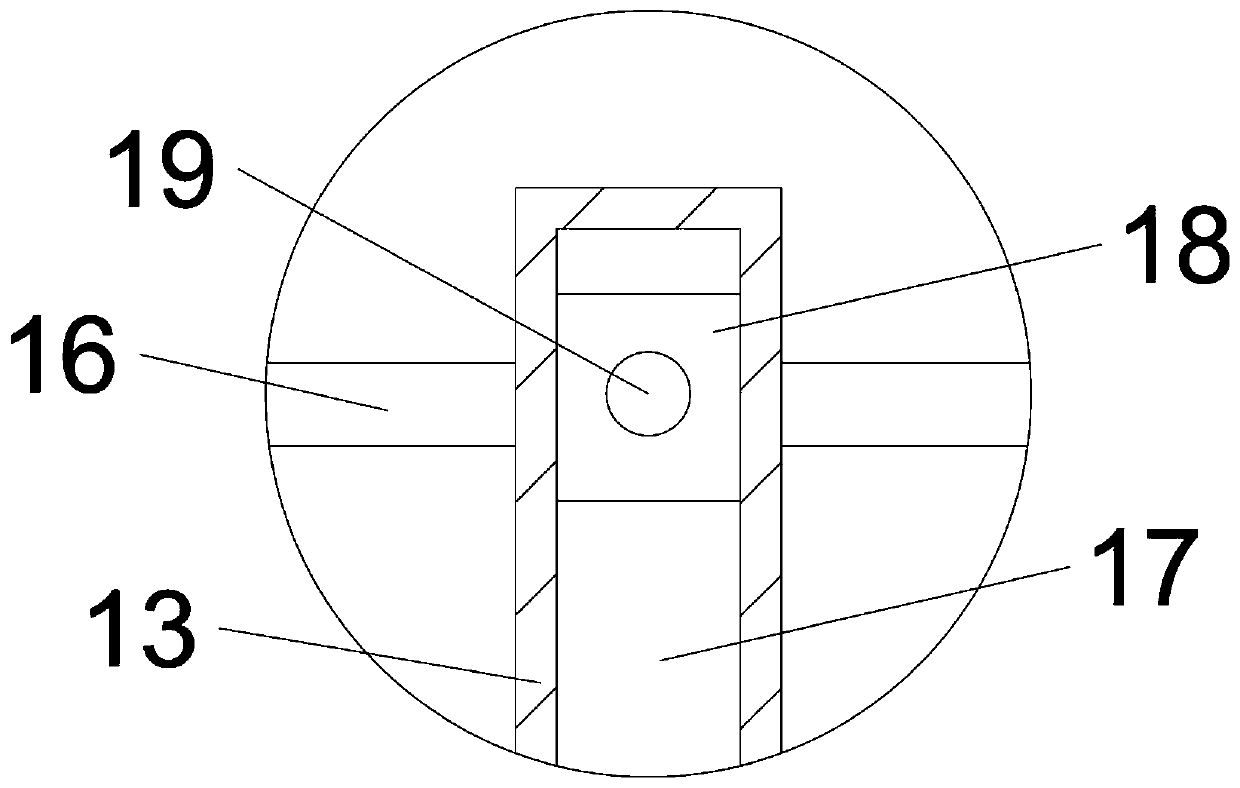

[0026] Further, the lower part of the paint spray pipe 5 is rotated and provided with a clamping assembly for fixing wood; the paint spray pipe 5 is fixed on the bottom of the slider 11, and the slider 11 is slidably matched with the guide rod 12. The guide rod 12 is fixed between two groups of brackets 2; the...

Embodiment 2

[0035] Please refer to the attached Figure 4 In order to facilitate the recovery of excess paint in the painting process, this embodiment is improved on the basis of Embodiment 1. Specifically, a recovery tank 36 is provided under the fixed frame 8, and the recovery tank 36 is connected with a Paint discharge pipe 37. A part of the paint sprayed by the paint spray pipe 5 is sprayed on the wood, and the remaining part is sprayed into the recovery tank 36, thereby reducing the waste of paint.

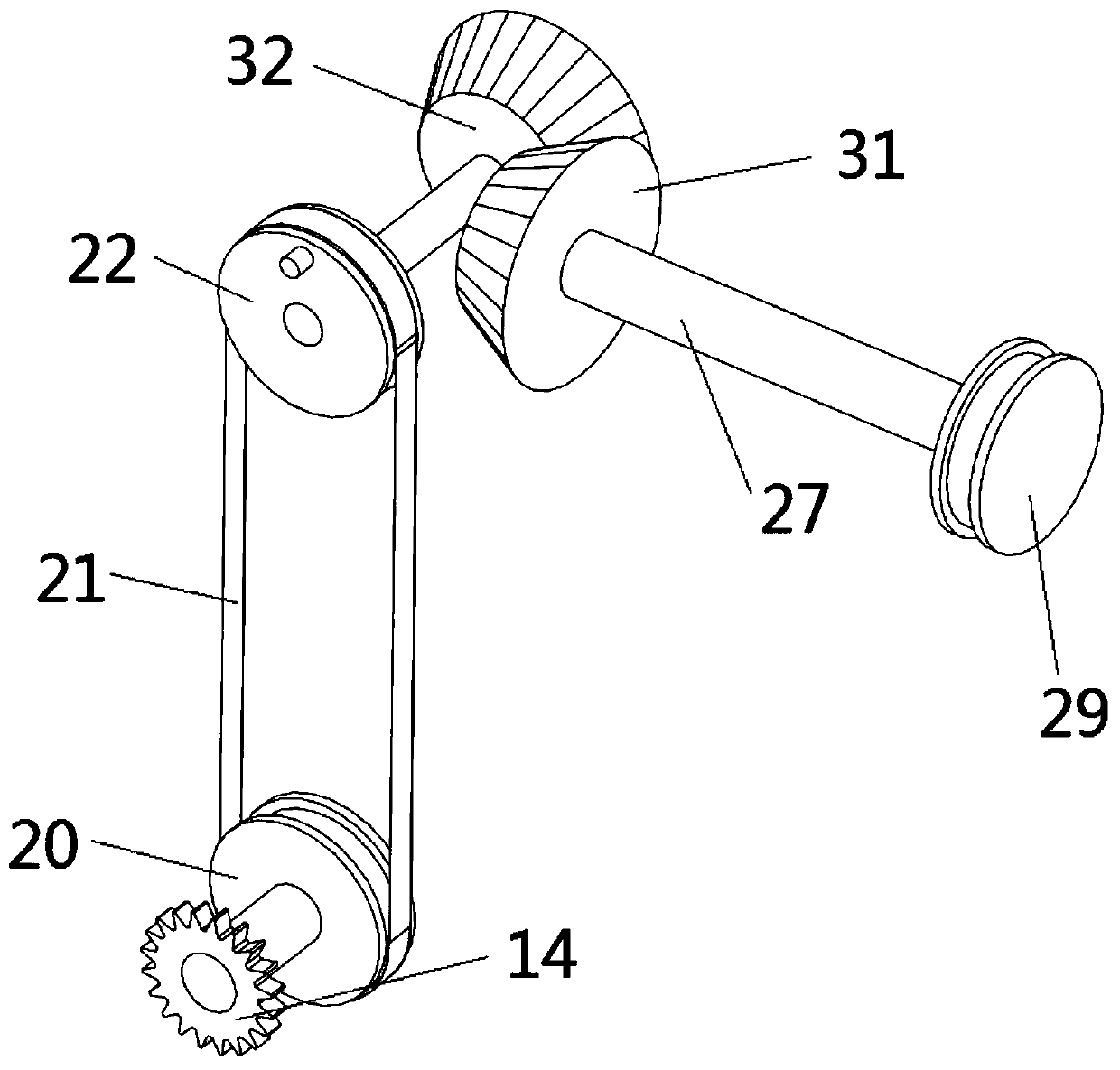

[0036] In summary, the paint spraying device provided by the embodiment of the present invention connects the paint spray pipe 5 with the slide block 11, and connects the slide block 11 with the connecting plate 13, the first transmission wheel 14, the second transmission wheel 15 and the traction The reciprocating assembly of the part 16 is connected, and the paint spraying pipe 5 can be driven to reciprocate on the horizontal plane through the driving mechanism and the transmission as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com