Horizontal pinned hydraulic system of crawler crane counterweight

A technology of crawler crane and hydraulic system, applied in the field of hydraulic control system and crawler crane, can solve the problems of self-pulling out, crane body tilting, hidden dangers, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

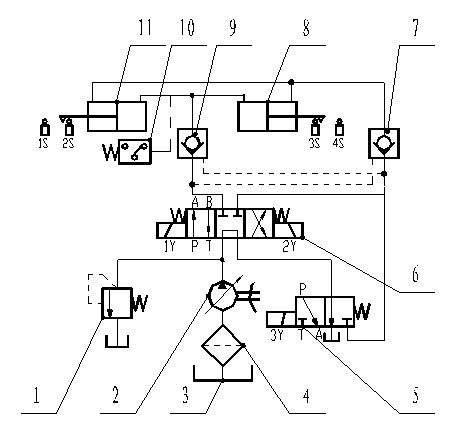

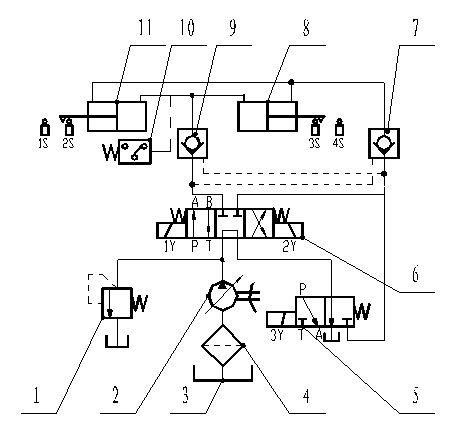

[0010] An embodiment of the present invention will be further described below in conjunction with accompanying drawing: (straighten out the following content)

[0011] The horizontal pinning hydraulic system of the crawler crane counterweight of the present invention is mainly composed of a variable pump 2, an oil tank 3, an oil filter 4, a three-position four-way electromagnetic reversing valve 6, a two-position three-way electromagnetic reversing valve 5, a hydraulic control unit Directional valve, pressure relay 10 and thread pin oil cylinder 11,8 constitute. The two pin-through cylinders 11 and 8 are arranged symmetrically on the vertical plate at the rear of the turntable of the crawler crane. The piston rod sides of the two pin-through cylinders 11 and 8 are respectively provided with travel switches for controlling the travel of the piston rods, and the travel switches are respectively fixed on the crawler belts. On the counterweight of the crane, the inlet pipelines of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com