Vacuum pipeline fluid film suspension vehicle system

A technology of vacuum pipes and fluid membranes, applied in tunnel systems, sliding/floating railway systems, roads, etc., can solve problems such as increasing train weight, system complexity, and loud noise, and achieves elimination of induced resistance, reduction of interference resistance, and high efficiency driving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

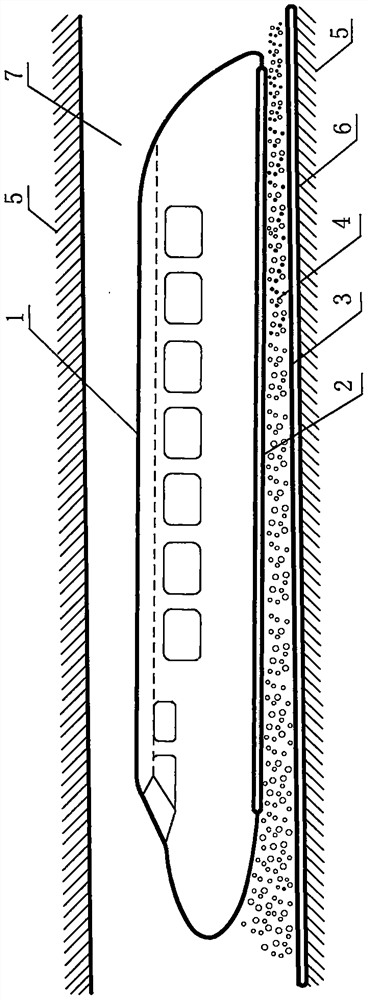

[0017] Combine below figure 1 To illustrate this embodiment, the embodiment of the vacuum pipeline fluid film suspension vehicle of the present invention includes: a fluid film suspension vehicle compartment 1, a linear motor primary 2, a linear motor secondary 3, a fluid film 4, a vacuum pipeline 5, a track surface 6, and a vacuum tube The low pressure space in the road 7, etc. The basic idea of the present invention is to combine the low-pressure vacuum pipeline train with the fluid film suspension vehicle, reduce the running resistance of the train to the greatest extent, and realize the high-speed, high-efficiency, stable and reliable suspension running of the train.

[0018] Such as figure 1 As shown, the power device of the fluid film suspension vehicle is composed of the primary 2 of the linear motor installed on the train chassis and the secondary 3 of the linear motor installed on the track surface, and the electromagnetic driving force is generated by controlling ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com