Energy-saving power generating and heating system using submerged arc furnace waste heat

An energy-saving power generation and heating system technology, applied in the field of waste heat recovery and utilization in the metallurgical process, can solve the problems of structural load and high manufacturing cost of waste heat power generation system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

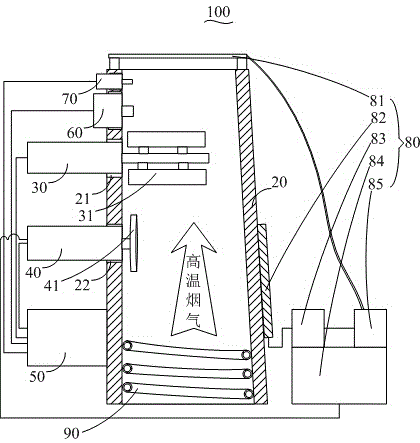

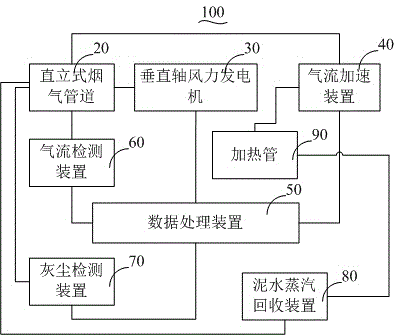

[0015] Please see also figure 2 and image 3 The submerged arc furnace waste heat energy-saving power generation heating system 100 includes a vertical flue gas pipeline 20 , a vertical axis wind generator 30 , an airflow acceleration device 40 , a data processing device 50 , a muddy water vapor recovery device 80 , and a heat exchange tube 90 .

[0016] The pipe wall of the vertical flue gas pipe 20 is provided with a first fixing hole 21 and a second fixing hole 22, the first fixing hole 21 is located above the second fixing hole 22, and the vertical axis wind generator 30 passes through the first fixing hole 21 and fixed with the vertical flue gas duct 20, the blade 31 of the vertical axis wind power generator 30 is located in the vertical flue gas duct 20, and the rotation axis of the wind wheel of the vertical axis wind power generator 30 is connected with the vertical flue gas duct 20 The central axis is vertical, the airflow accelerating device 40 passes through the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com