Multistage centrifugal high pressure liquefied hydrocarbon pump

A centrifugal, liquefied hydrocarbon technology, used in non-variable-capacity pumps, non-displacement pumps, pumps, etc., can solve the problems affecting the self-flushing pressure stability of mechanical seals, mechanical seal damage, leakage, etc., to improve operation reliability. performance and service life, reduce energy consumption, and ensure safe and reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

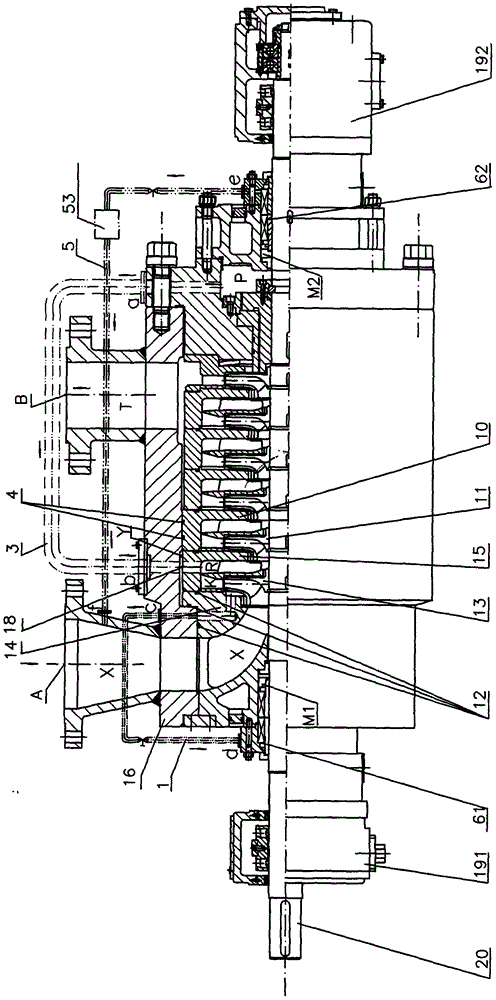

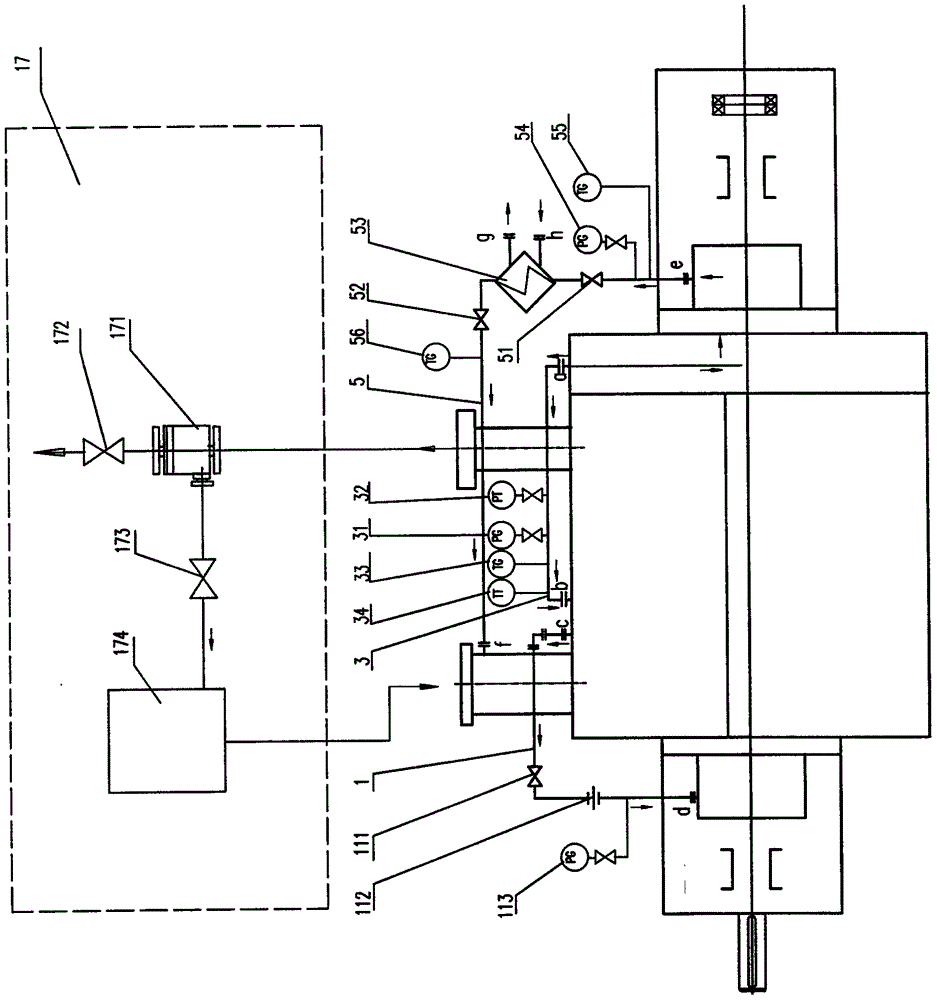

[0014] Such as figure 1 As shown, the multistage centrifugal high-pressure liquefied hydrocarbon pump of the present invention includes an axial force balance mechanism, a mechanical seal self-flushing mechanism, bearing components (including a left bearing assembly 191 and a right bearing assembly 192), and a rotating shaft 20. The axial force balance The mechanism includes the balance return pipe assembly 3, the middle section of the pump (including the first-stage middle section 15 and the second-stage middle section 10), the impeller (including the first-stage impeller 13 and the second-stage impeller 11), the balance drum 7 (and the balance drum sleeve 8), the suction Body 14, pump cover 9, outer cylinder 16, the mechanical seal self-flushing mechanism includes forward flushing pipe assembly 1, reverse flushing pipe assembly 5, mechanical seal components (including driving side mechanical seal assembly 61 and non-driving side mechanical Seal assembly 62), which has a bala...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com