Cooling method used for directional solidification and cooling device therefor

A technology of directional solidification and cooling method, applied in the field of spray cooling devices, can solve the problems of slow cooling rate, complex production conditions, high cooling rate and other problems of single crystal, and achieve the effect of large temperature gradient, large temperature gradient and not easy to vaporize

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

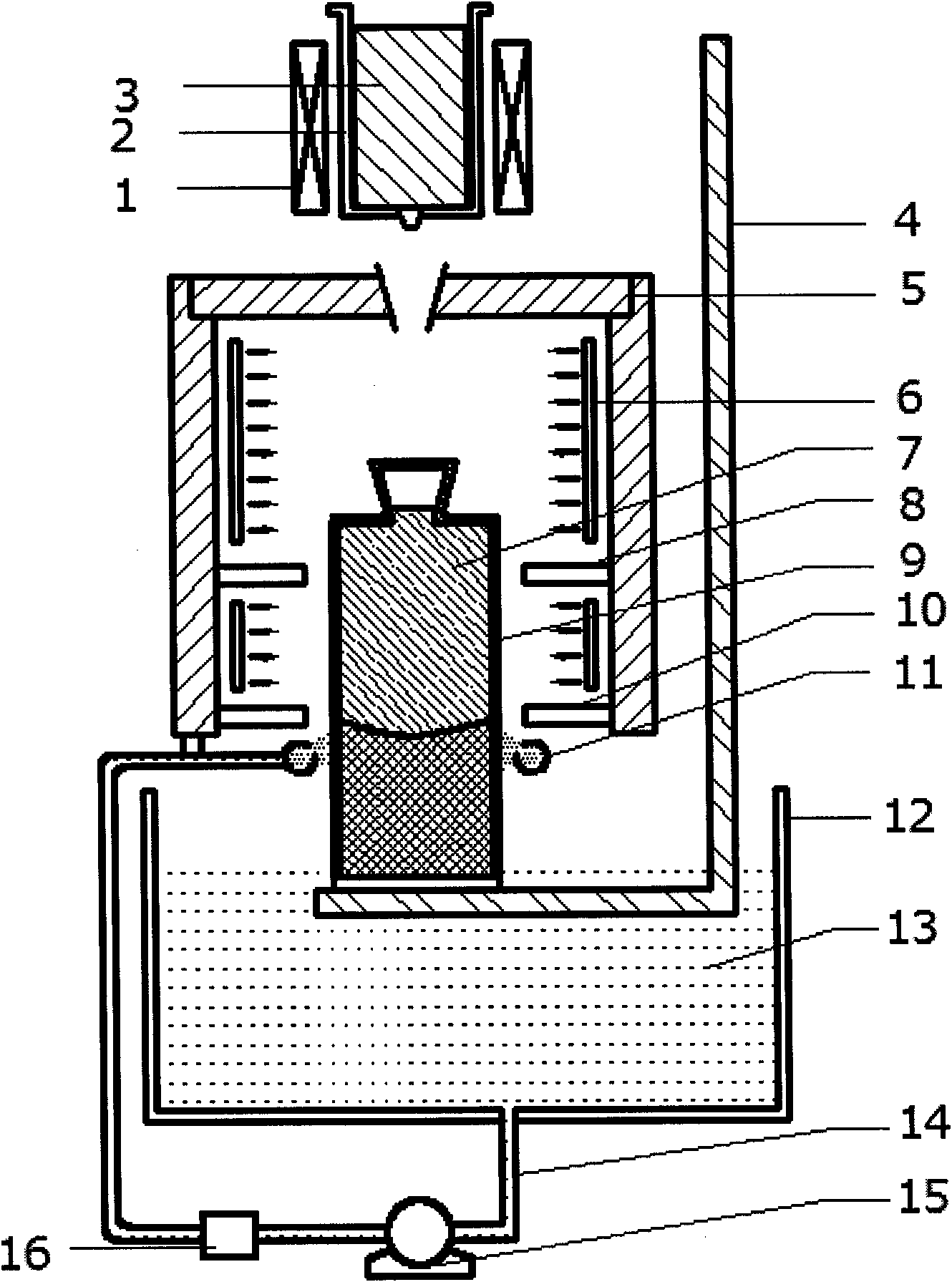

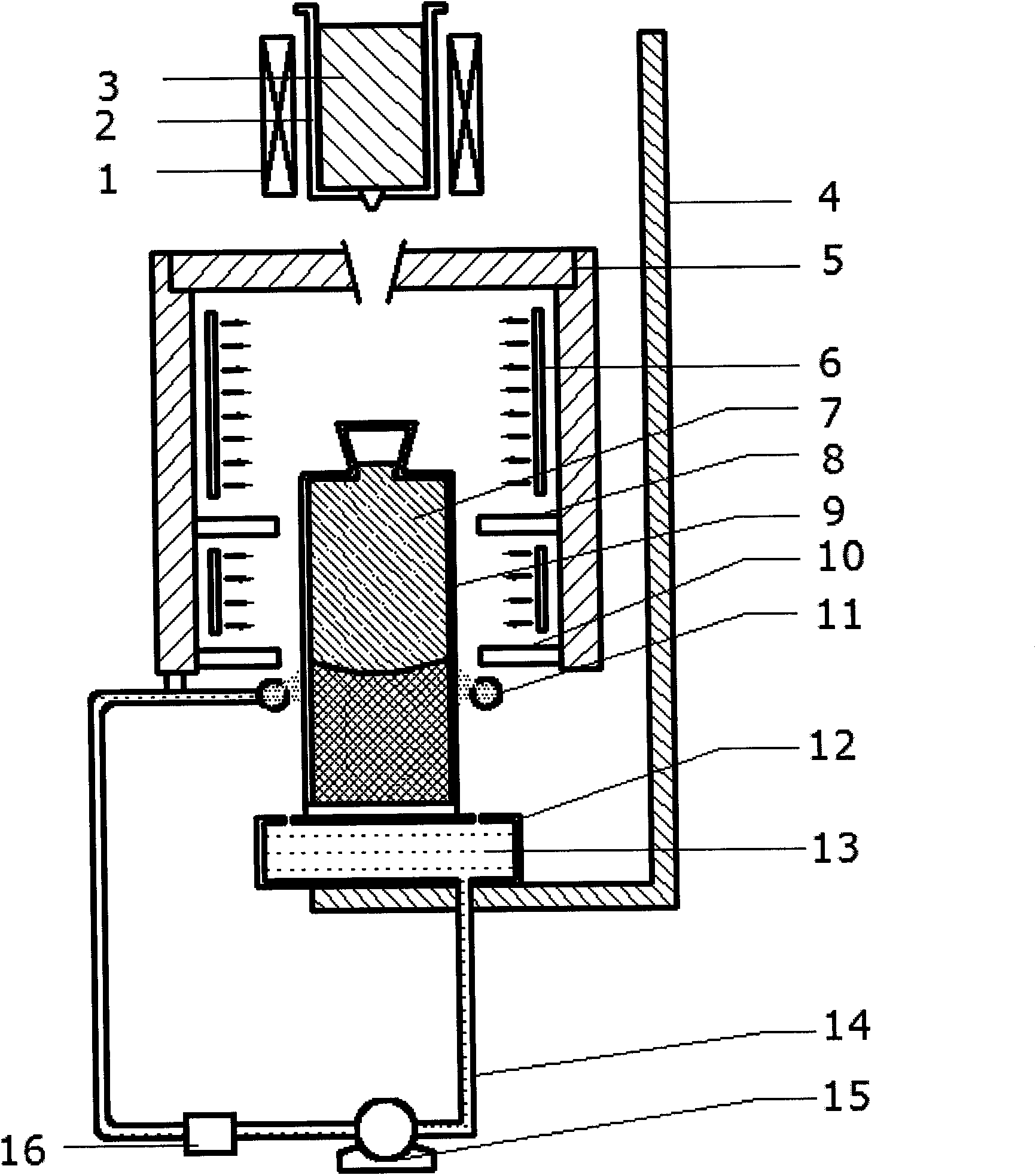

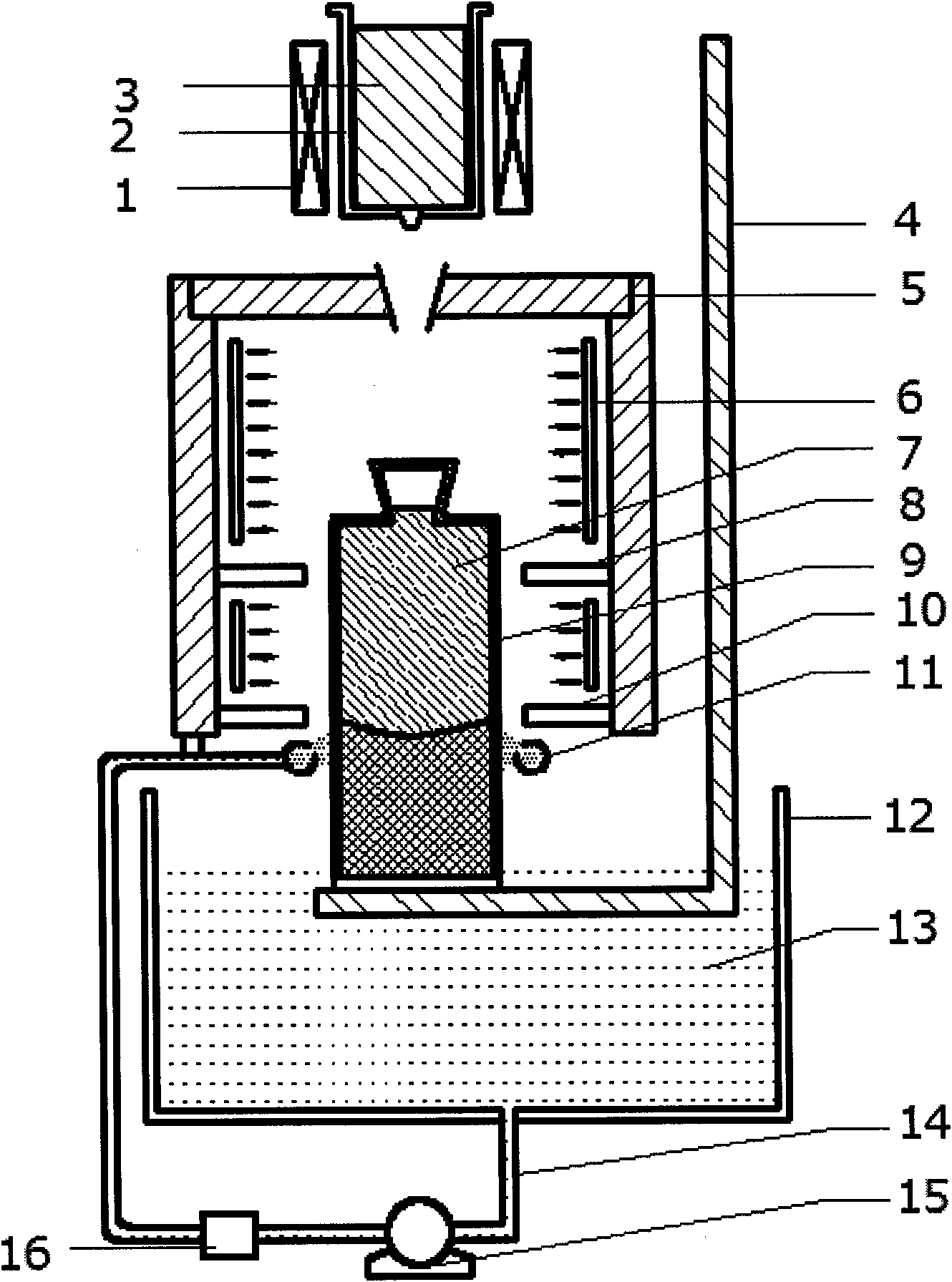

[0034] Embodiment one: see figure 1 and figure 2 , This cooling method for directional solidification uses liquid metal as the cooling liquid, and the mold shell is sprayed alone, or the spray cooling method and the immersion cooling method are carried out at the same time.

Embodiment 2

[0035] Embodiment two: if figure 1 As shown, the immersion cooling device used for directional solidification includes a melting furnace 2 with a heating coil 1, a holding furnace 5, a mold shell 9 and a liquid reservoir 12, and the upper cover of the holding furnace 5 has a pouring The smelting furnace 2 with the heating coil 1 is arranged above the pouring port, the liquid outlet at the bottom of the smelting furnace 2 is aligned with the pouring port on the upper cover of the holding furnace 5, and the inner chamber of the holding furnace 5 It can accommodate the formwork 9, and there is an upper heat insulation board 8 in the middle of the inner cavity to divide the inner cavity of the holding furnace 5 into an upper heating zone 6 and a lower heating zone. There is a lower heat insulation board 10; an annular nozzle 11 is arranged on the lower edge of the holding furnace 5, and the annular nozzle 11 is connected to the outlet of the pump 15 through a cooling system 16, an...

Embodiment 3

[0036] Embodiment three: see figure 1 , the technical process of the immersion cooling method for directional solidification is as follows: the heating coil 1 in the melting furnace 2 melts the solid superalloy 3, and then injects it into the mold shell 9 in the holding furnace 5; after the pouring is completed, the mold shell 9 Move down with the drawing device 4, and immerse in the cooling liquid 13 at the lower part to cool down, so that the temperature gradient inside the mold shell 9 is always upward; at the same time, the annular nozzle 11 starts to work, spraying the cooling liquid 13 around the mold shell, because the cooling liquid 13 is distributed in a ring shape, so it can effectively isolate the heat radiation between the heating zone and the cooling zone; the mold shell moves downward, the heat is absorbed by the cooling liquid on the lower part and the side wall, and the overall temperature gradient is vertically upward, making the melting Superalloy 7 is gradua...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com