Acid-resistant glass fiber and fabric prepared by glass fiber

A glass fiber and acid-resistant technology, which is applied in the field of acid-resistant glass fiber and fabrics prepared therefrom, can solve the problems of unsatisfactory filtration of flue gas, requirement of flue gas emission rate, and increased energy consumption, etc. High temperature resistance and corrosion resistance, ensuring post-processing processability and good high temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

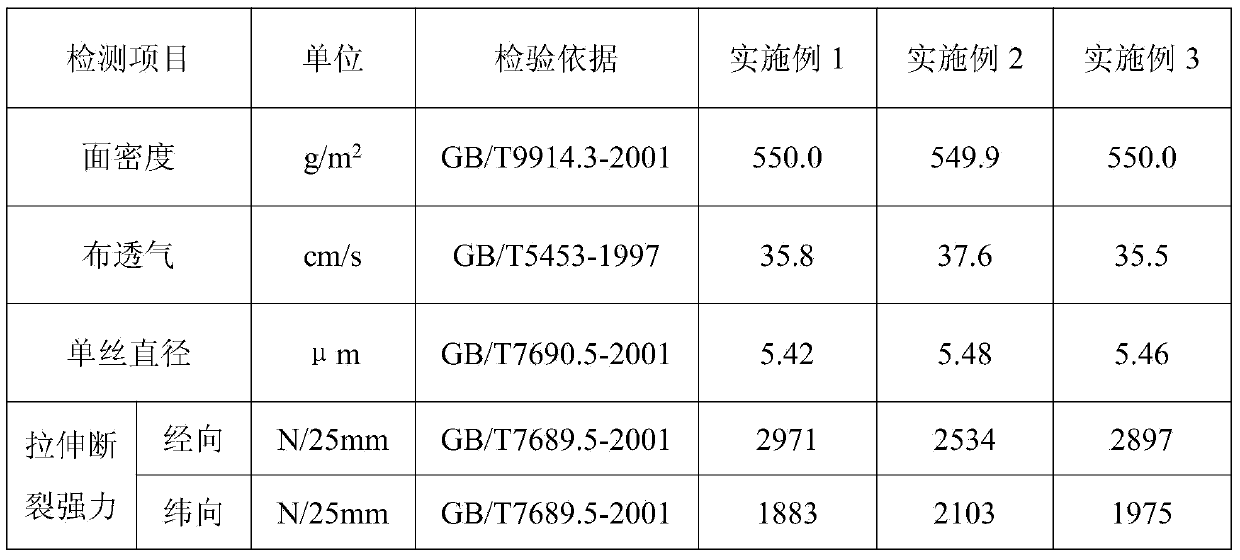

[0026] 1) The raw material components of glass fiber are listed in Table 1. The fiber is drawn by a general-purpose crucible or pool kiln, and the glass fiber is drawn into a 37.5tex raw silk, and the raw silk is coated with a textile-type compound emulsion (brand TS -1101, produced by the Special Fiber Division of Sinoma Science and Technology), and then made into 150tex warp yarns through the process of unwinding and twisting, and warping the finished warp yarns, and drawing them into warp yarn heads;

[0027] 2) Use the same composition of glass fiber to draw 37.5tex raw silk, the raw silk is coated with the same proportion of textile-type compound emulsion, and the raw silk is decomposed to make 75tex unidirectional twisted yarn; drawn with the same composition of glass fiber Make the 31.5tex raw silk, the raw silk is coated with bulking textile type sizing agent, and make 126tex yarn through de-solution and twisting process, and then go through bulking treatment; Plying a...

Embodiment 2

[0034] 1) The raw material components of the glass fiber are listed in Table 3, and the fiber is drawn by using a general-purpose crucible or a pool kiln, and the glass fiber is drawn into a 12.5tex precursor, and the precursor is a textile-type compound emulsion (same as Example 1) Coating treatment, and then through the unwinding and twisting process to make 150tex warp yarns; the warp yarns made are warped and harnessed to make warp yarn heads;

[0035] 2) Use the same composition of glass fiber to draw 12.5tex raw silk, and the raw silk is coated with the same proportion of textile-type compound emulsion, and the raw silk is decomposed to make 75tex unidirectional twisted yarn; drawn with the same composition of glass fiber 12.5tex raw silk is made, the raw silk is coated with bulking textile sizing agent, and 125tex yarn is made through the unwinding and twisting process, and then bulked; Plying and twisting into weft yarn; the ratio of the bulking textile sizing agent us...

Embodiment 3

[0042] 1) The raw material components of the glass fiber are listed in Table 5, and the fiber is drawn by using a general-purpose crucible or a pool kiln, and the glass fiber is drawn into a 37.5tex precursor, and the precursor is a textile-type compound emulsion (same as Example 1) Coating treatment, after the process of retreating and twisting to make 150tex warp yarn, warp the finished warp yarn, and draw it into a warp yarn head;

[0043] 2) Use the same composition of glass fiber to draw 37.5tex raw silk, the raw silk is coated with the same proportion of textile-type compound emulsion, and the raw silk is decomposed to make 75tex unidirectional twisted yarn; drawn with the same composition of glass fiber 12.5tex raw silk is made, the raw silk is coated with bulking textile sizing agent, and 125tex yarn is made through the unwinding and twisting process, and then bulked; Ply and twist into weft yarn; see Table 6 for the proportion of bulking textile sizing used;

[0044]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com