Purification method of odor waste gas produced by high-temperature dewatering of sludge

A high temperature, exhaust gas technology, applied in chemical instruments and methods, separation methods, air quality improvement, etc., can solve the problems of low deodorization efficiency, increased energy consumption, difficulty in maintaining activity, etc., achieve good low temperature survival performance, increase wastewater treatment Burden, low-cost odor treatment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

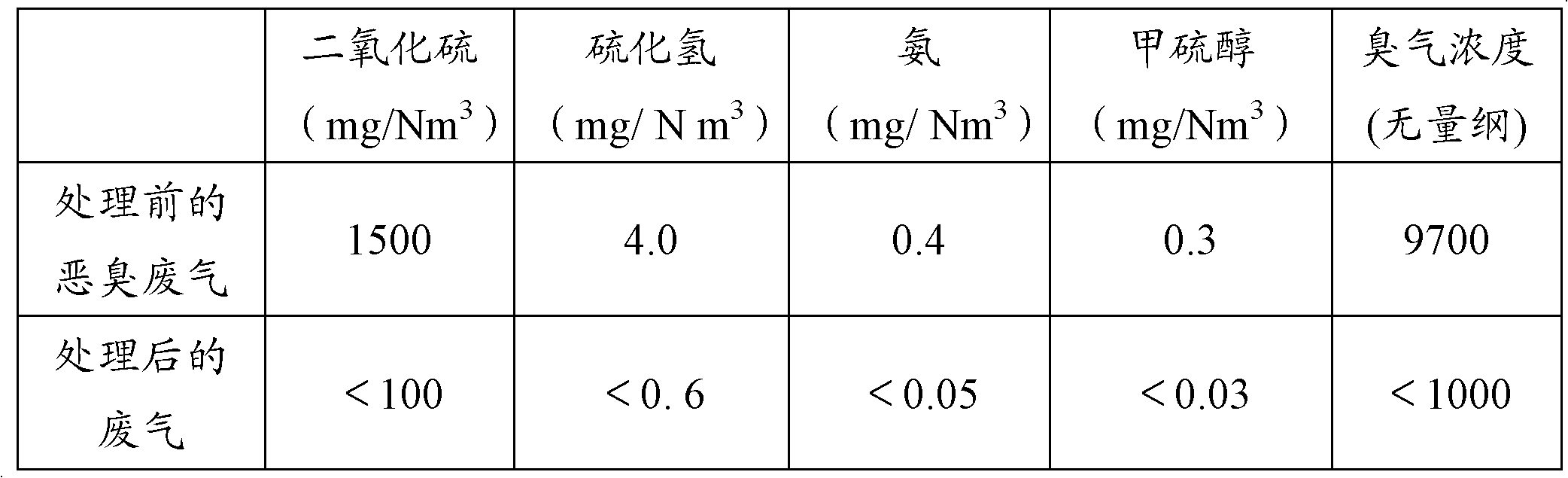

[0040] The method for purifying the malodorous waste gas produced by high-temperature dehydration of sludge described in this embodiment comprises the following steps:

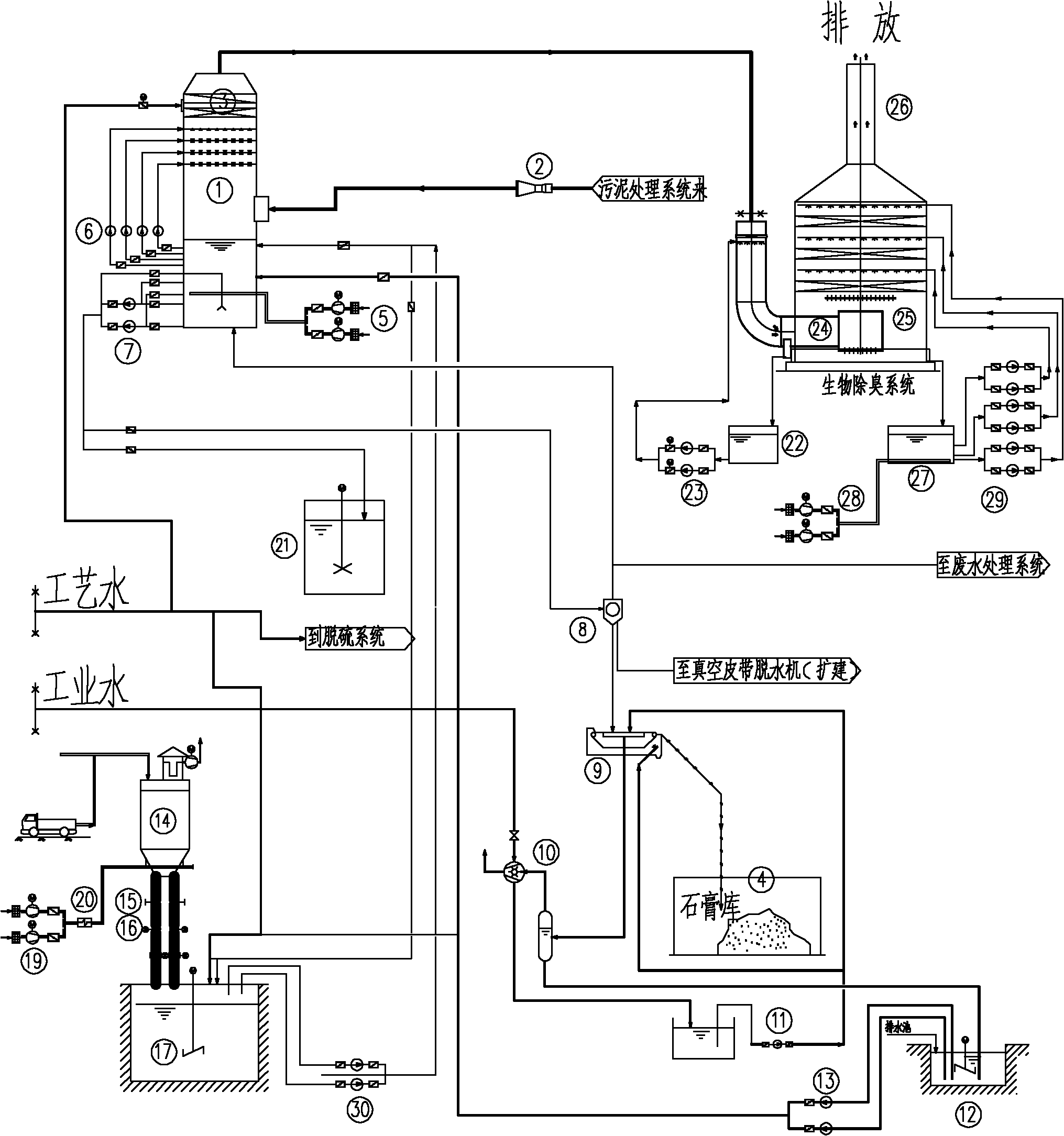

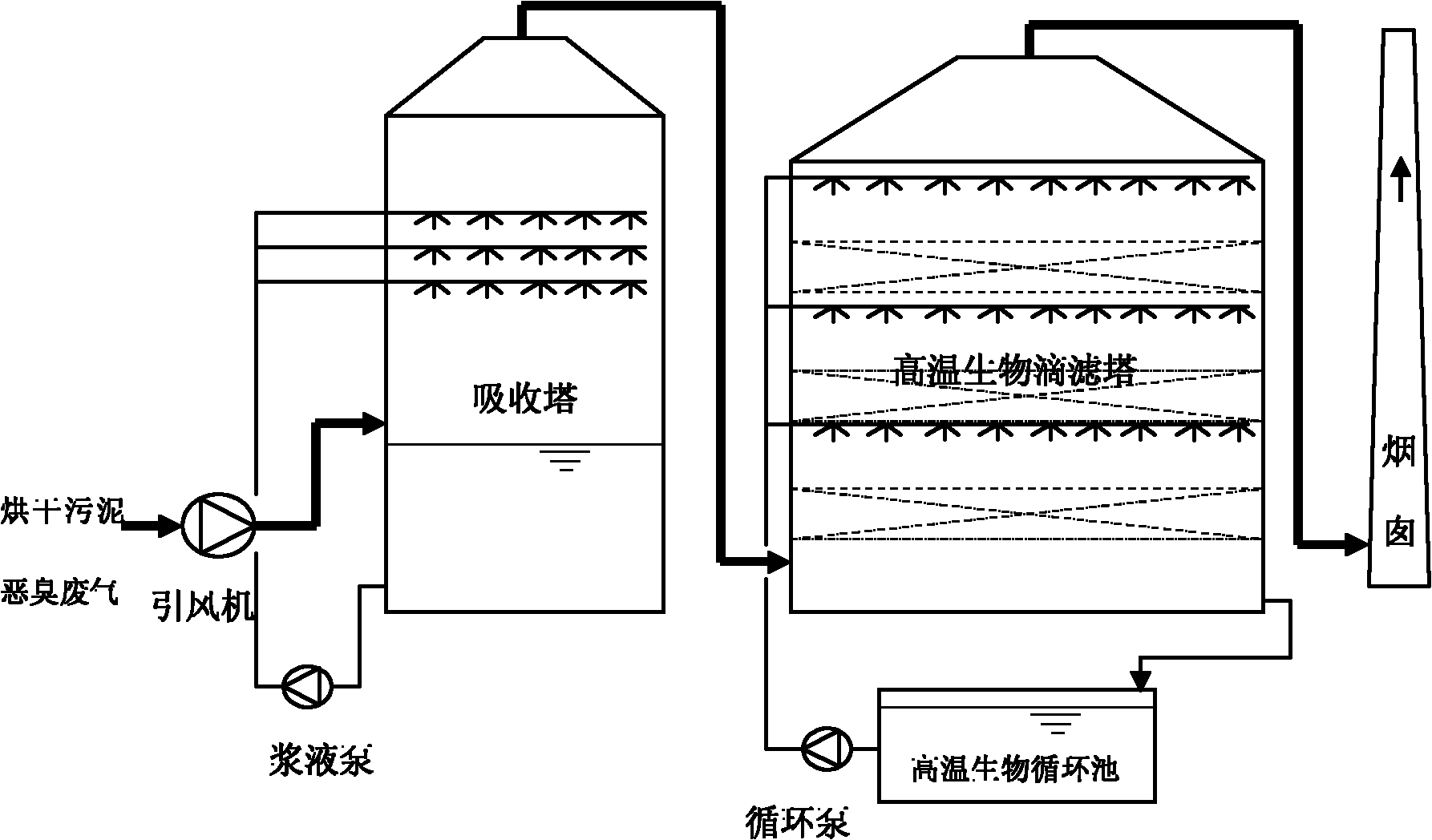

[0041] (1) Limestone-gypsum desulfurization system to remove SO 2 ;Limestone-gypsum desulfurization system mainly includes absorption tower, limestone slurry circulating spray system, flue system, defogging system, limestone slurry preparation system and gypsum dehydration system;

[0042] The malodorous exhaust gas is sent from the bottom of the absorption tower to the absorption tower through the pressurization of the induced draft fan, and the temperature of the smoke entering the tower is controlled at 110-130°C, and the slurry spray volume is 15L / Nm 3 , the number of demisters is two, and the tower height is 32m. Measure SO in tower exhaust gas 2 Less than 50mg / L, and the temperature of the malodorous exhaust gas is between 55 and 64°C;

[0043] (2) High-temperature biological trickling filter deodoriz...

Embodiment 2

[0053] The method for purifying the malodorous waste gas produced by high-temperature dehydration of sludge described in this embodiment comprises the following steps:

[0054] (1) Limestone-gypsum desulfurization system to remove SO 2 ;Limestone-gypsum desulfurization system includes absorption tower, limestone slurry circulating spray system, flue system, demisting system, limestone slurry preparation system and gypsum dehydration system;

[0055] The malodorous exhaust gas is sent from the bottom of the absorption tower to the absorption tower through the pressurization of the induced draft fan, and the temperature of the smoke entering the tower is controlled at 110-130°C, and the slurry spray volume is 10L / Nm 3 , the number of demisters is two, and the tower height is 29m. Measure SO in tower exhaust gas 2 The concentration is lower than 50mg / L, and the temperature of the malodorous exhaust gas is between 55°C and 64°C; (2) The high-temperature biological trickling filt...

Embodiment 3

[0065] The method for purifying the malodorous waste gas produced by high-temperature dehydration of sludge described in this embodiment comprises the following steps:

[0066] (1) Limestone-gypsum desulfurization system to remove SO 2 ;Limestone-gypsum desulfurization system includes absorption tower, limestone slurry circulating spray system, flue system, demisting system, limestone slurry preparation system and gypsum dehydration system;

[0067] The malodorous exhaust gas is sent from the bottom of the absorption tower to the absorption tower through the pressurization of the induced draft fan, and the temperature of the smoke entering the tower is controlled at 110-130°C, and the slurry spray volume is 15L / Nm 3 , the number of demisters is two, and the tower height is 35m. Measure SO in tower exhaust gas 2 The concentration is lower than 50mg / L, and the temperature of the malodorous exhaust gas is between 55 and 64°C;

[0068](2) High-temperature biological trickling f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com