Polymerization esterification residual heat utilization method and apparatus

A technology of polymerizing ester and waste heat, applied in the field of polyester production, can solve problems such as energy waste, achieve the effects of reducing waste, obvious economic and social benefits, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

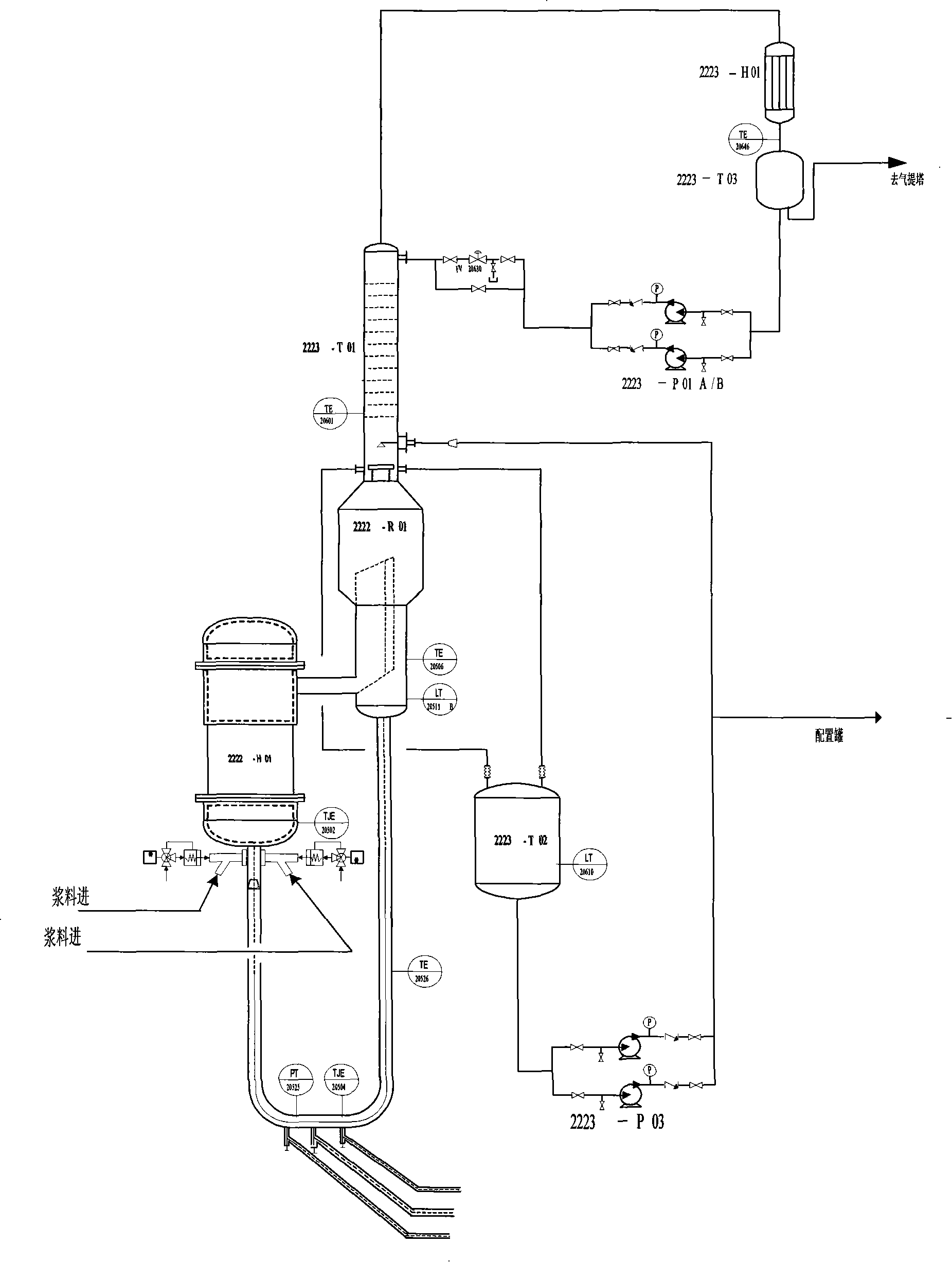

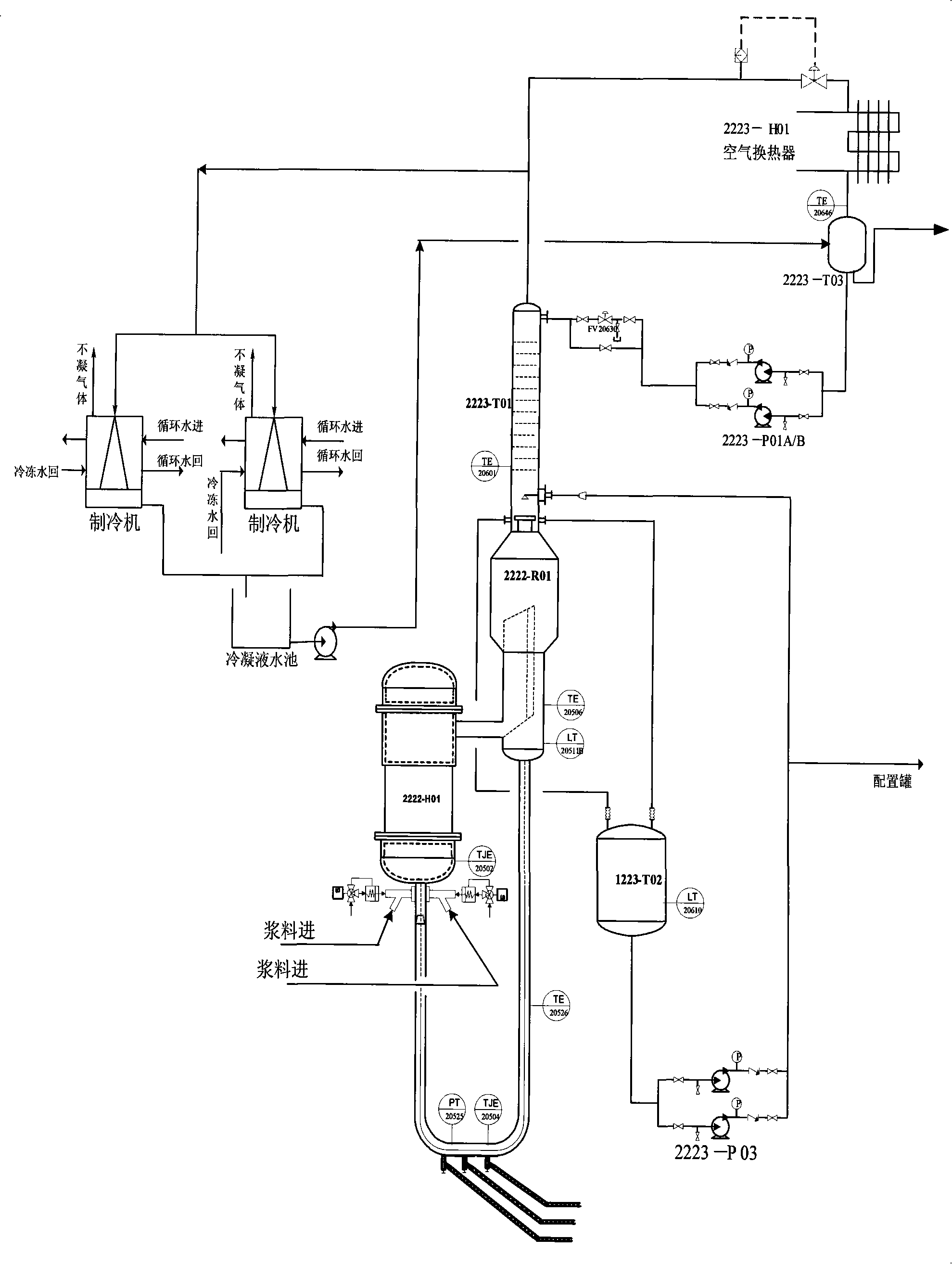

[0023] The present invention will be described in detail below in conjunction with the accompanying drawings: the present invention is an improvement to the prior art. network connection, so the attached figure 2 The esterification reactor, auxiliary equipment and separation tower in the figure 1 same as shown in .

[0024] The invention is attached figure 1 On the basis shown, a waste heat utilization device for polymerization esterification is added, and the waste heat utilization method for polymerization esterification is as follows: the waste steam at the top of the separation tower on the upper part of the esterification reactor is drawn and supplied to at least one lithium bromide refrigerator as a heat source, And set a collection tank at the condensed water outlet of the refrigerator, use a pump to send this part of water to the waste water collection tank, part of it is used as the return water at the top of the tower, and the rest overflows to the stripping tower...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com