Patents

Literature

35results about How to "Small draft" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

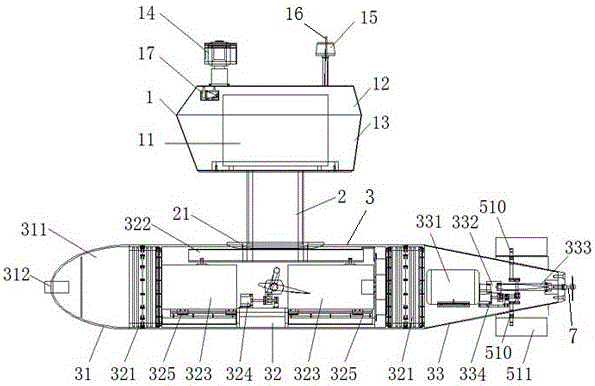

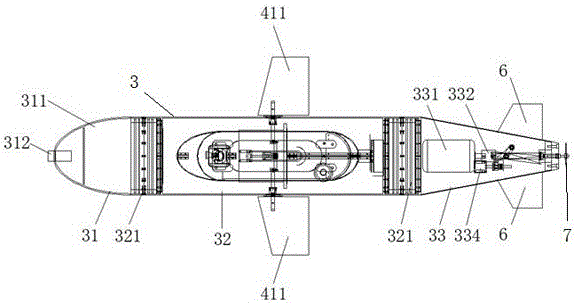

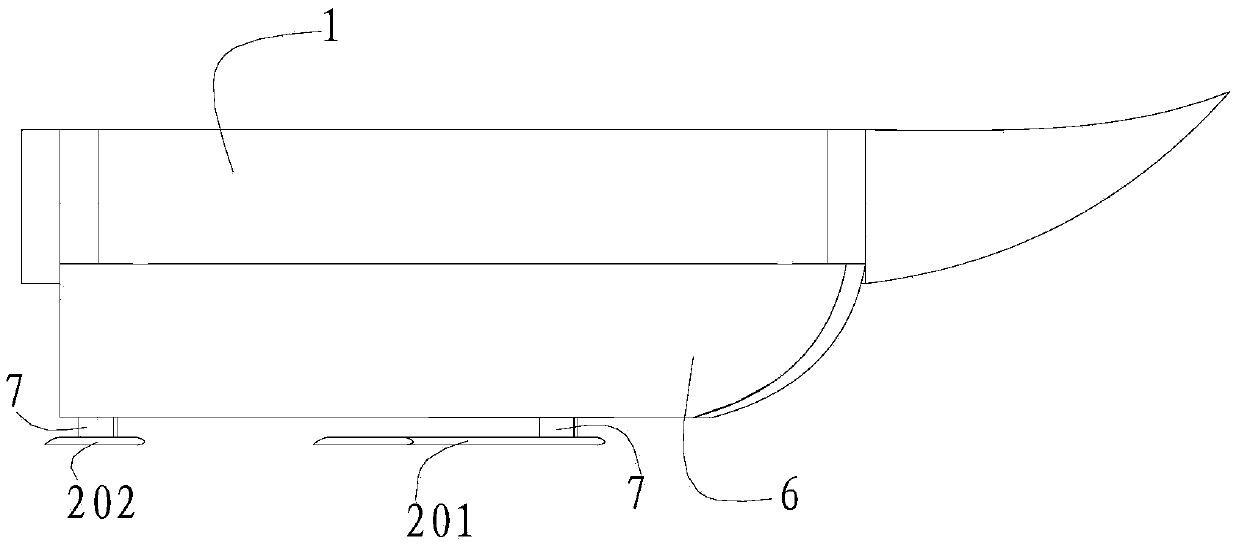

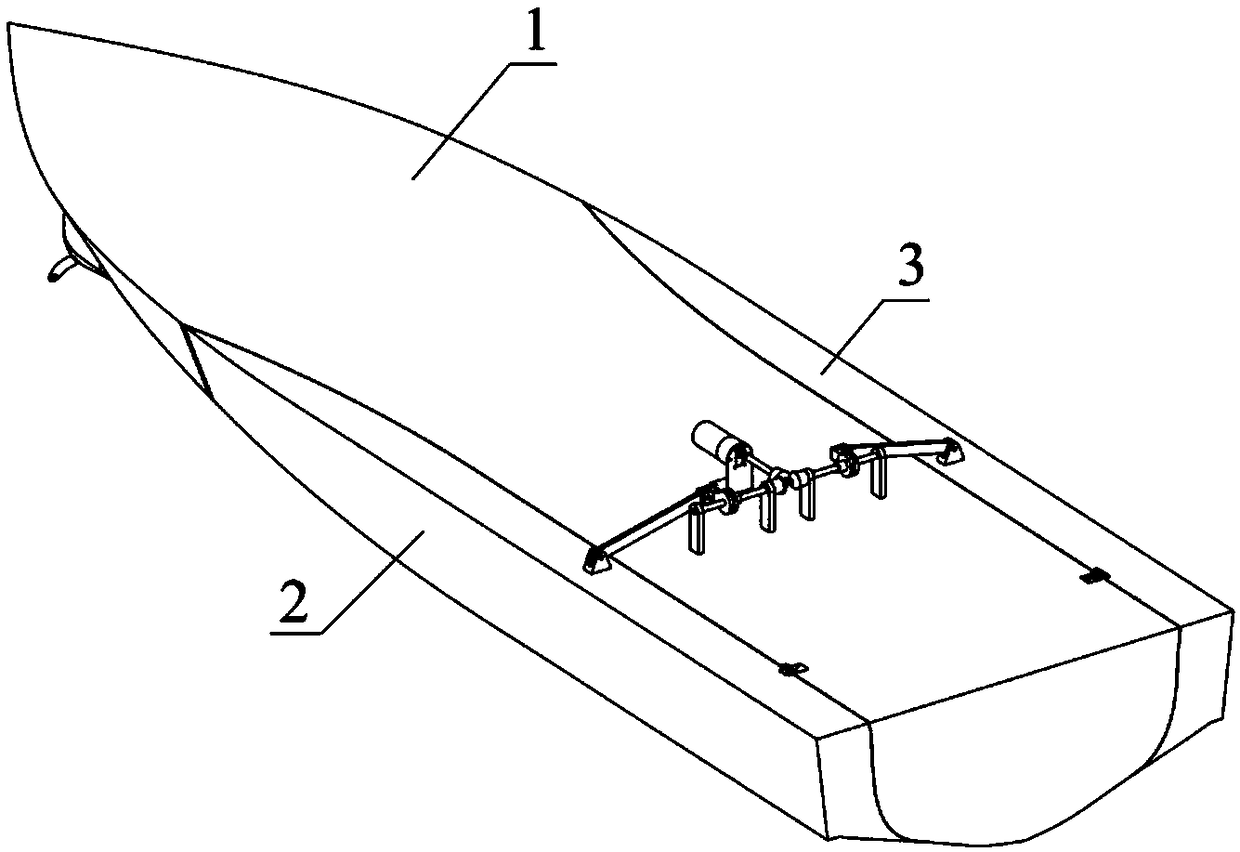

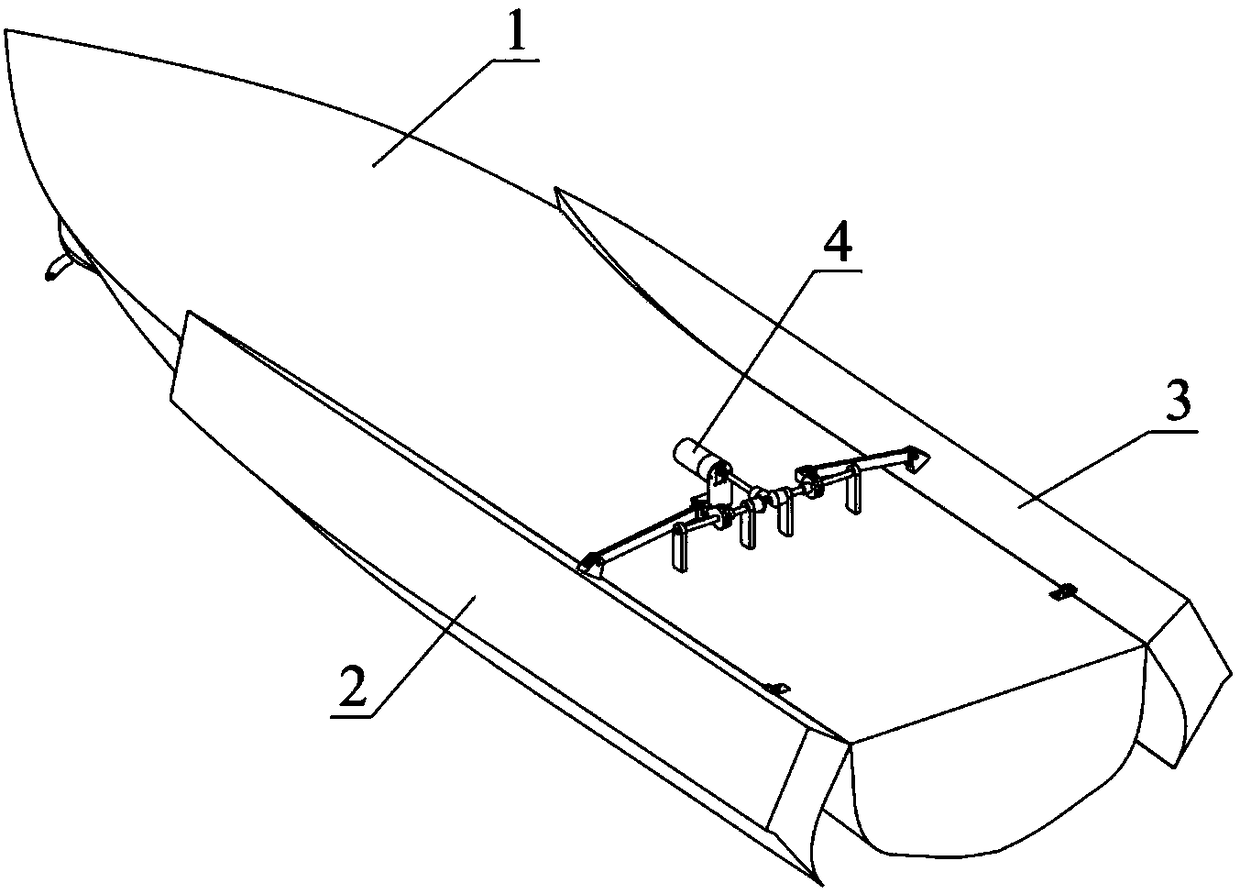

Stealth single-hull small waterline area hydrofoil unmanned ship and sailing method

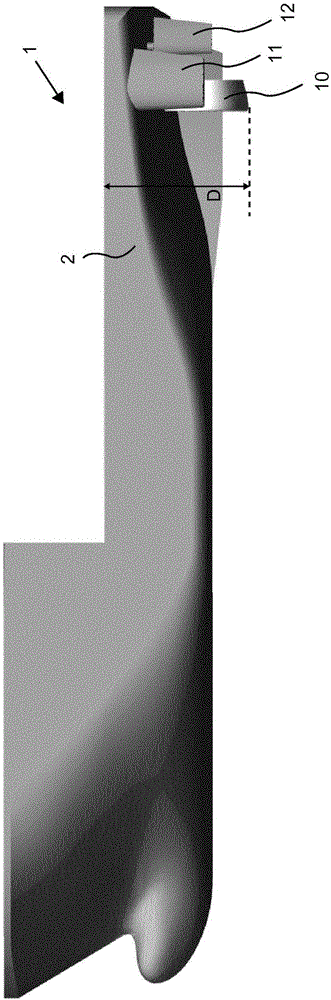

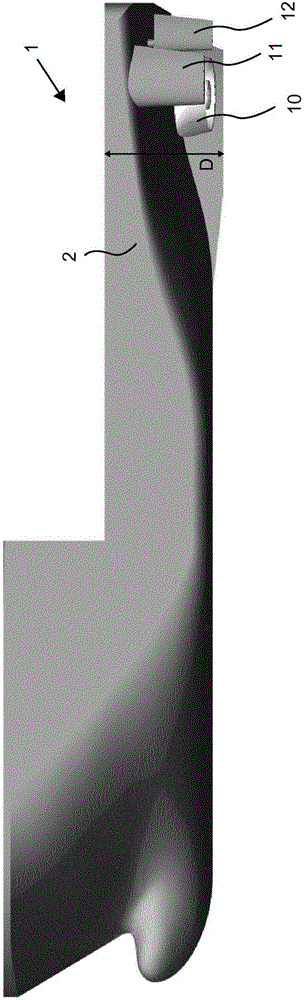

The invention discloses a stealth single-hull small waterline area hydrofoil unmanned ship sailing on water and a sailing method. The upper portion of the stealth single-hull small waterline area hydrofoil unmanned ship is provided with a control cabin, the middle portion comprises posts, and the lower portion is a submerged body. The front section of the submerged body is a submerged body bow, the middle section of the submerged body is a submerged body middle part, and the rear section of the submerged body is a submerged body stern. Two water ballast spaces, two power supply cell boxes and a hydrofoil control mechanism are arranged inside the submerged body middle part of a hull. The two water ballast spaces are symmetrically arranged front and back; the two power supply cell boxes symmetrical front and back are arranged between the two water ballast spaces; and the hydrofoil control mechanism is arranged in the center of the space between the two power supply cell boxes. A pair of hydrofoils is symmetrically arranged on the left side and the right side outside the submerged body middle part of the hull. A main motor, a coupler, a main shaft and a tail vane control mechanism are arranged inside the submerged body stern of the hull. A pair of tail vanes is symmetrically arranged on the left side and the right side outside the submerged body stern of the hull. The stealth single-hull small waterline area hydrofoil unmanned ship has excellent seakeeping, speedability and resistance properties, and can achieve the three navigational statuses of body navigation, winging operation and submerge navigation.

Owner:JIANGSU UNIV OF SCI & TECH +1

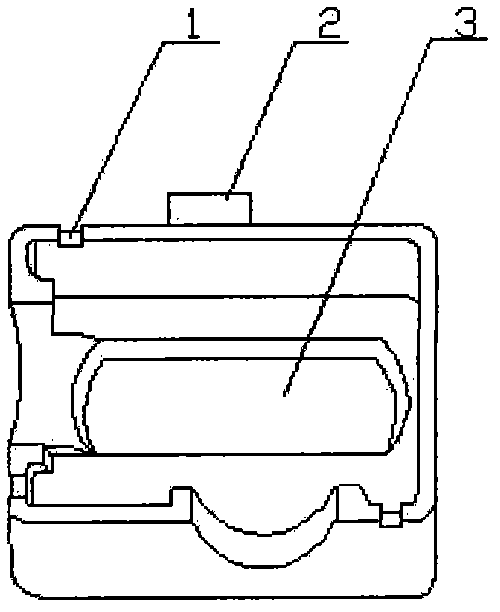

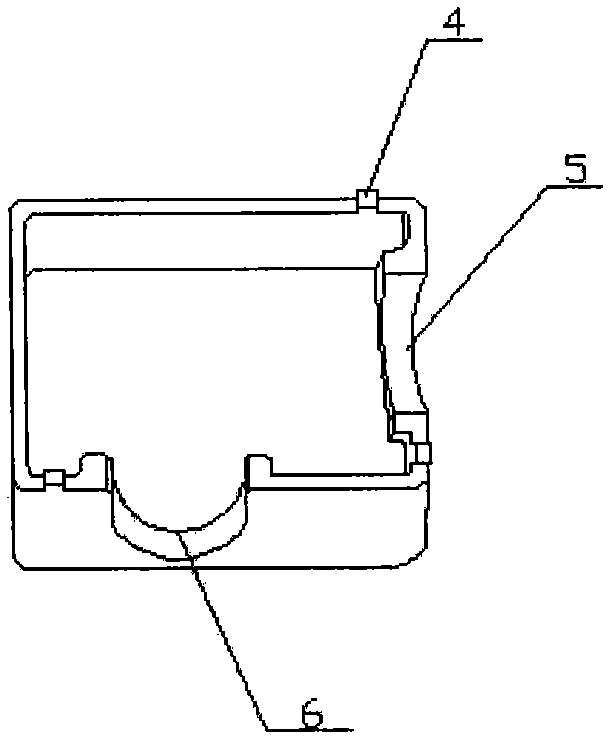

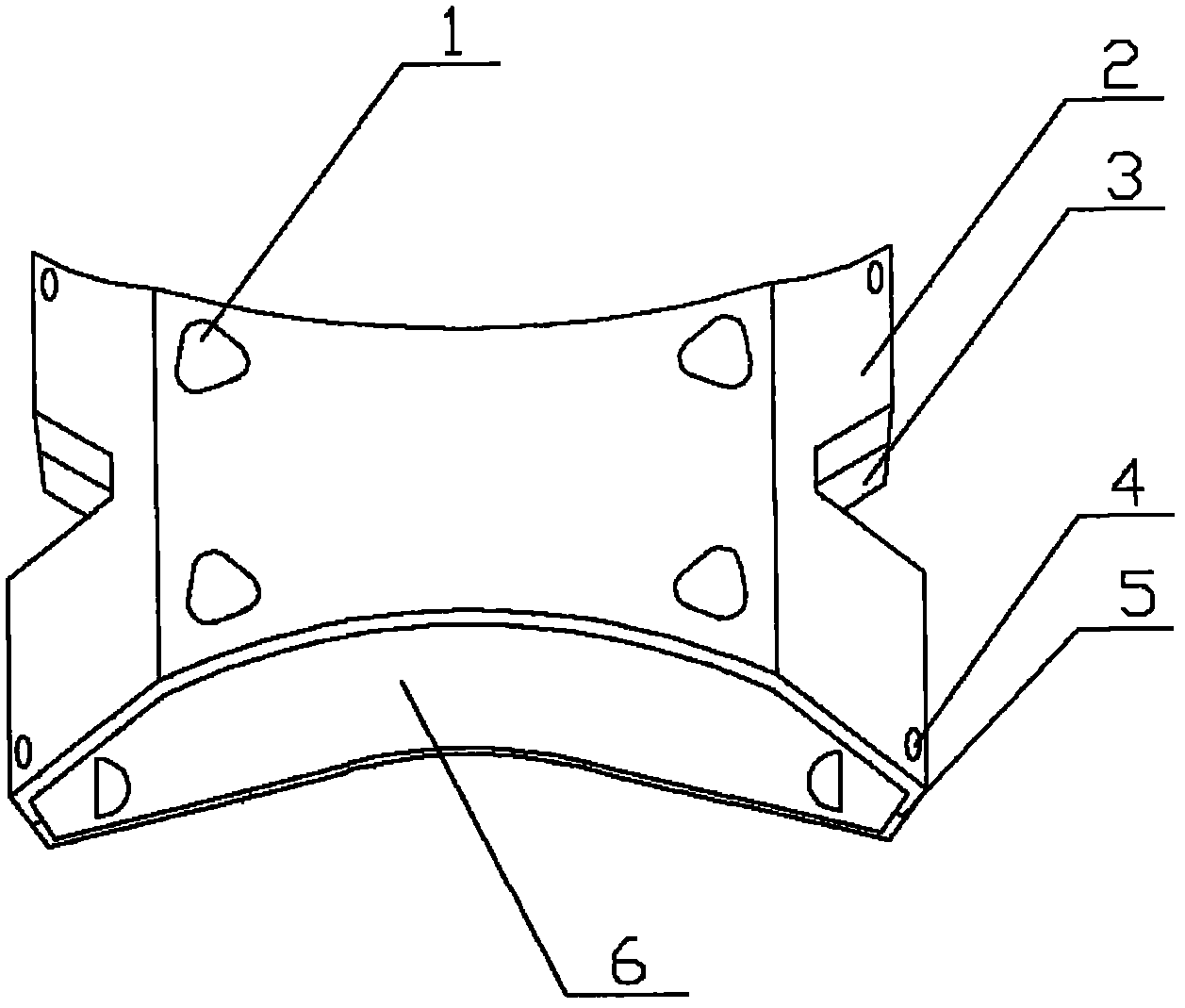

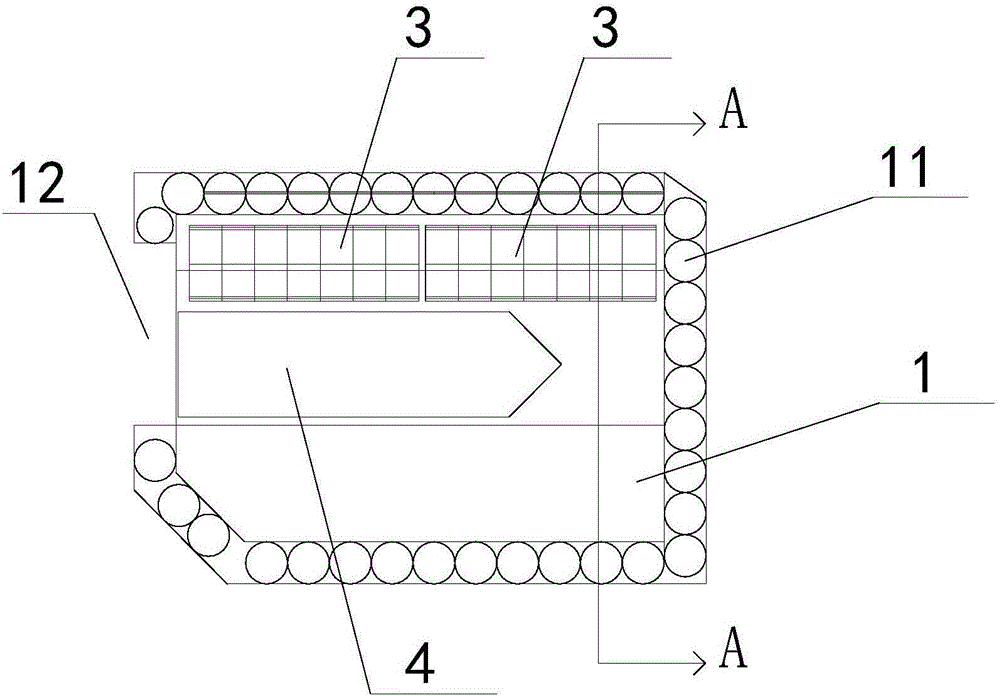

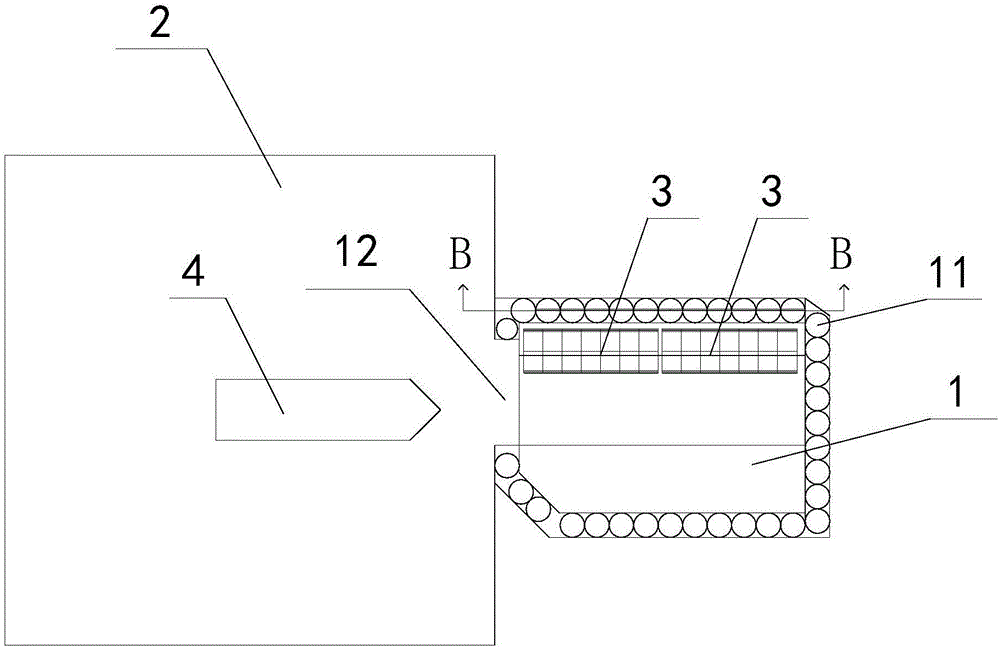

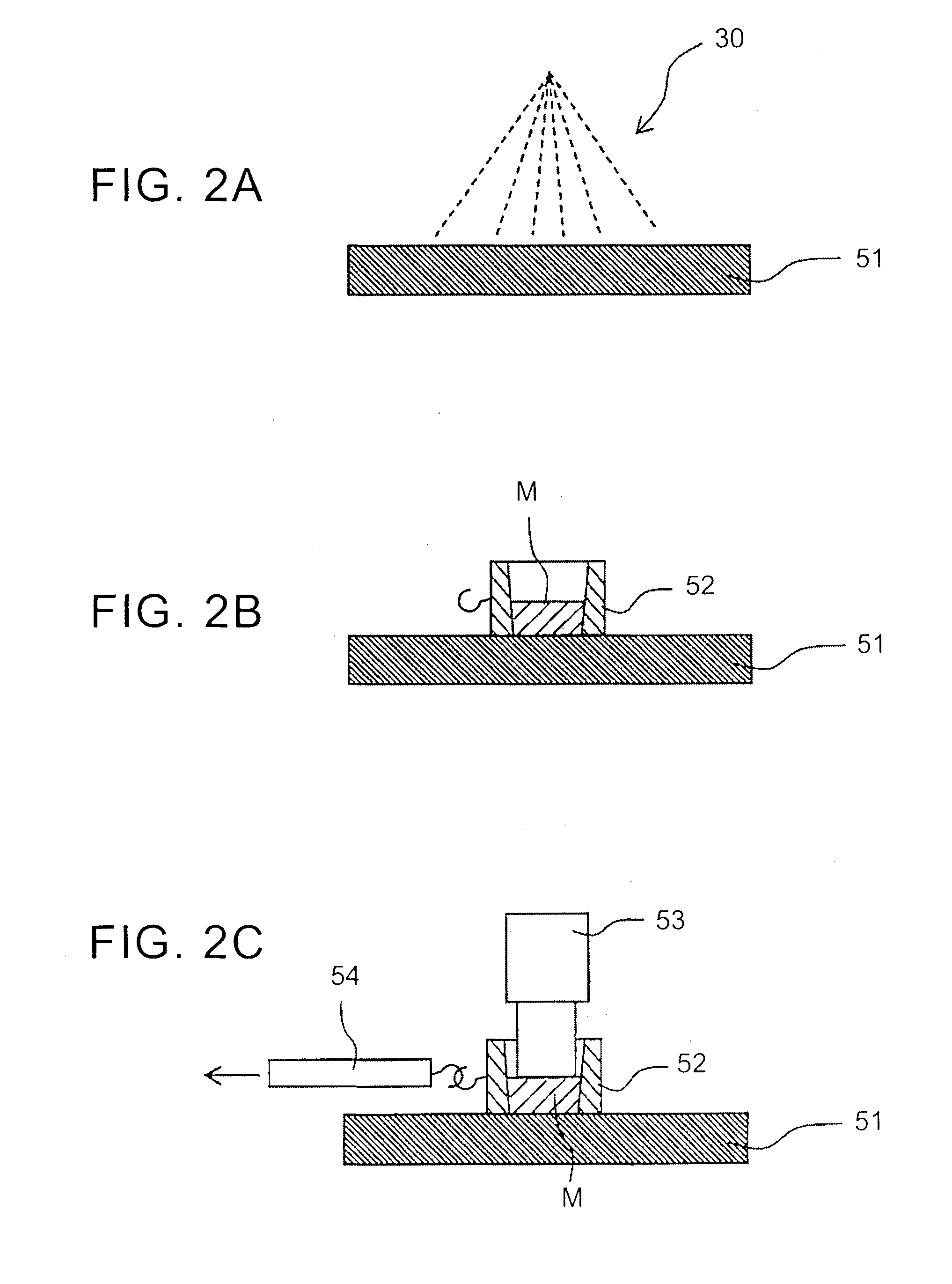

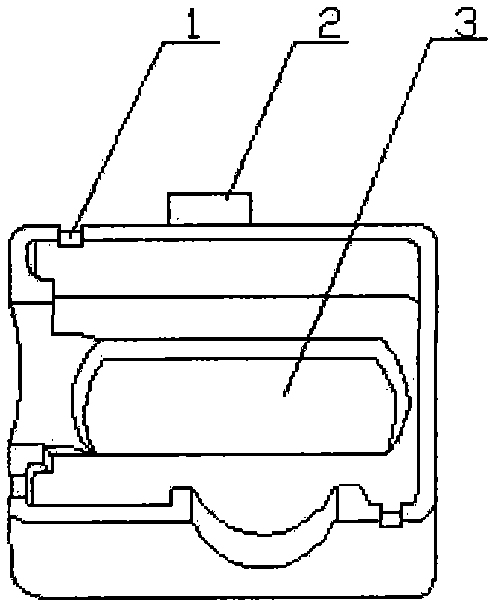

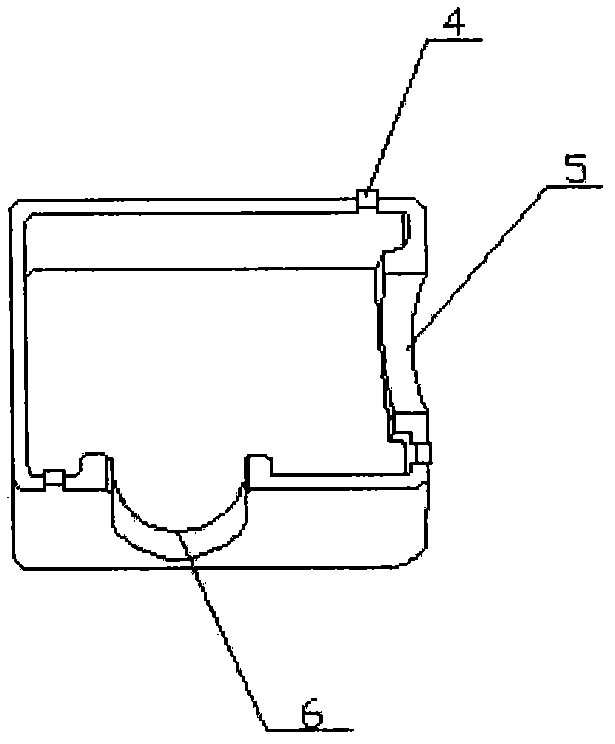

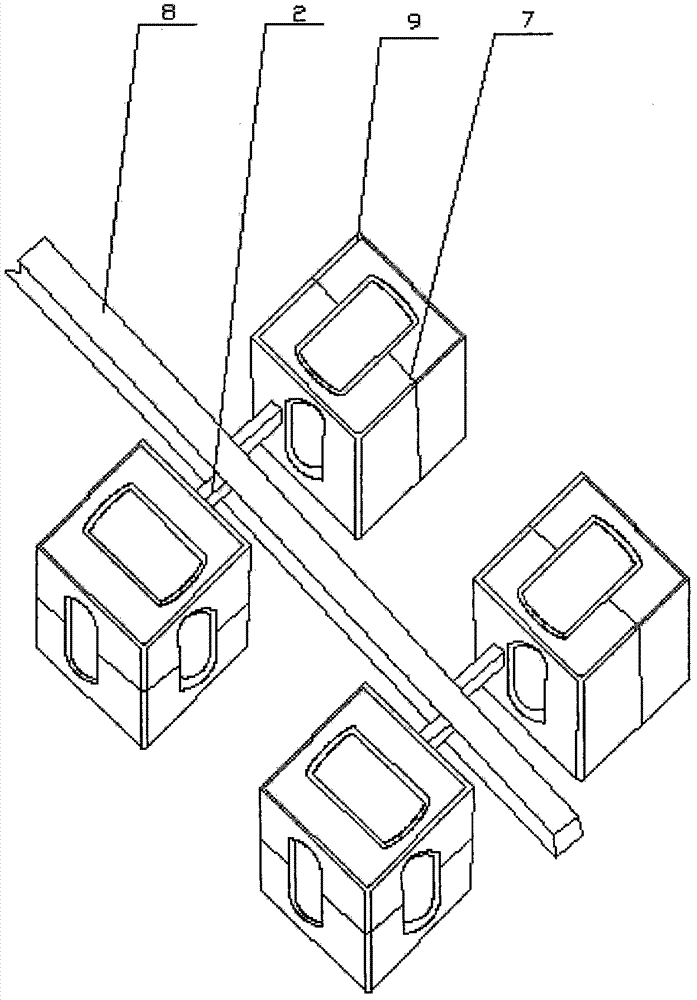

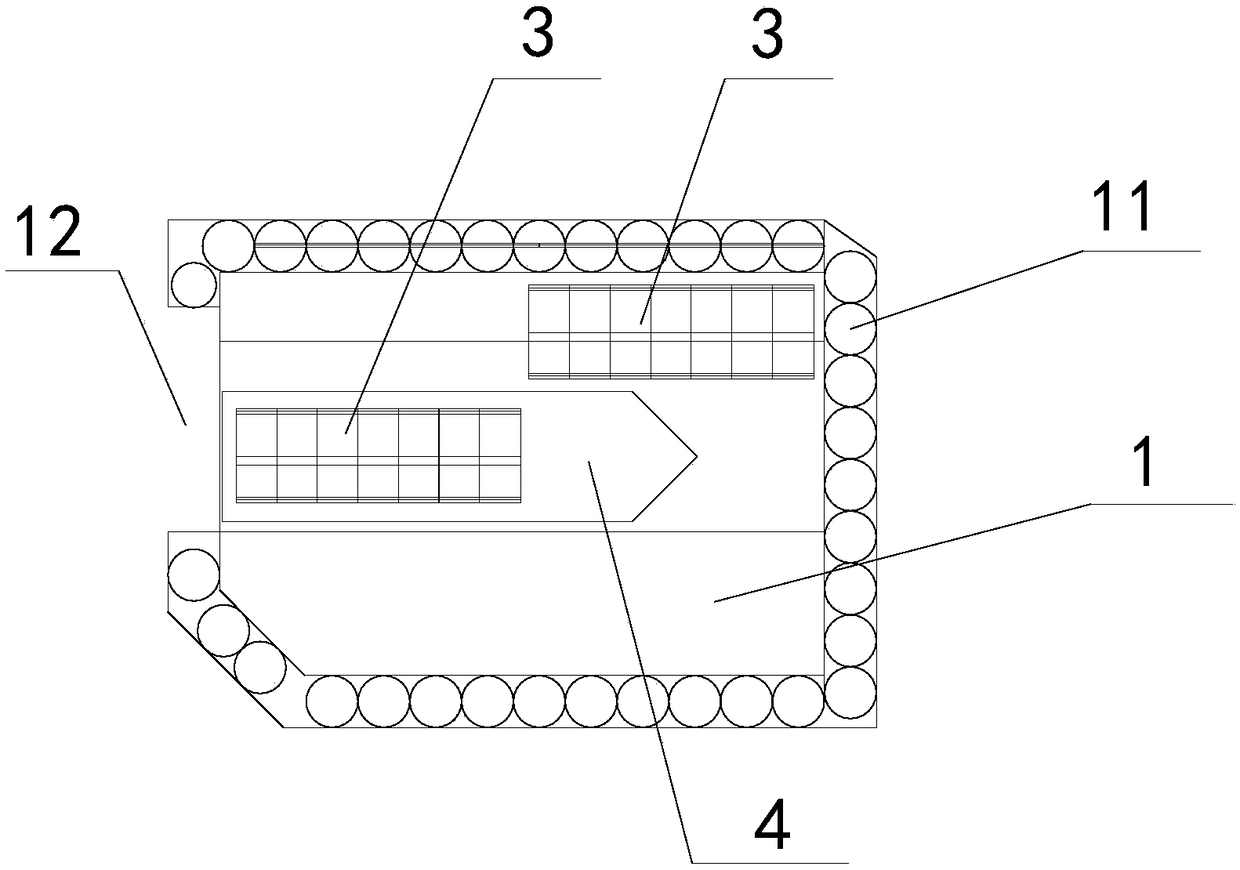

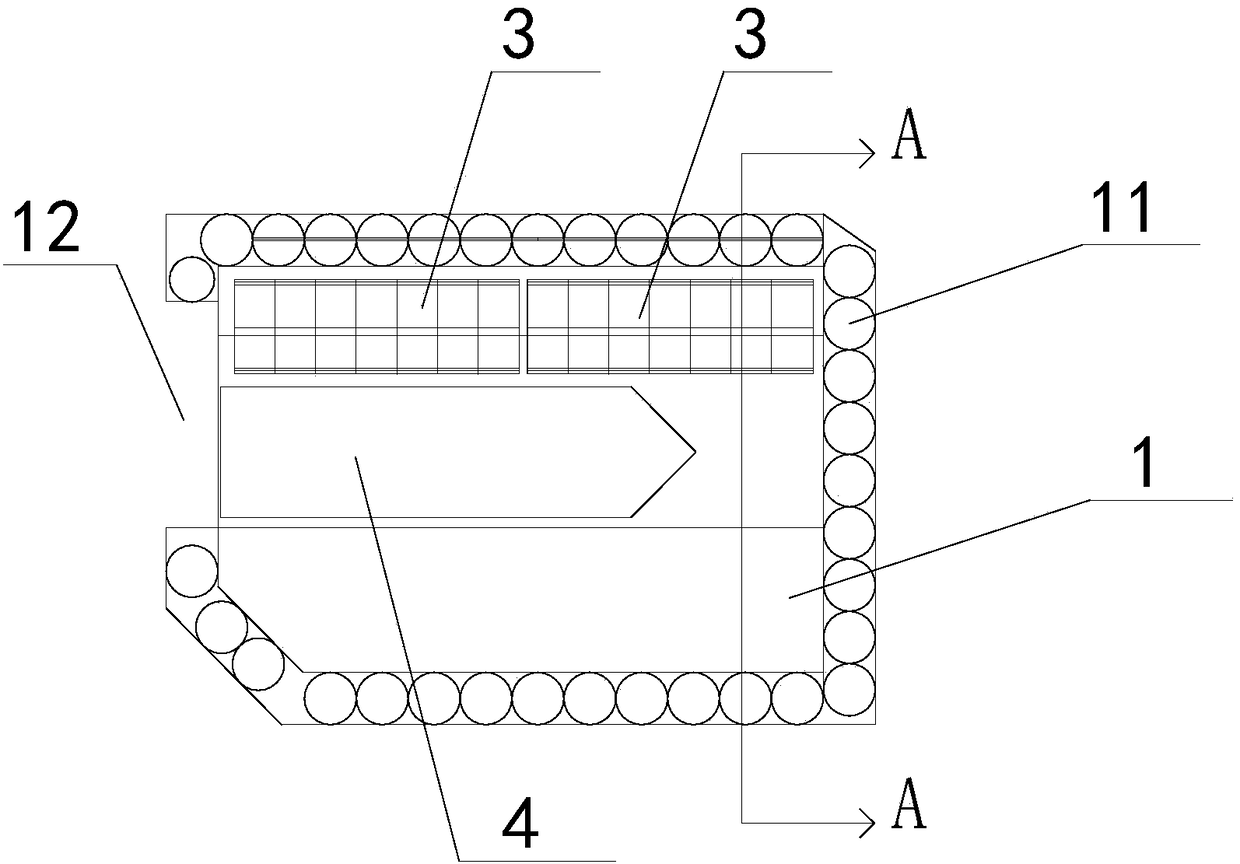

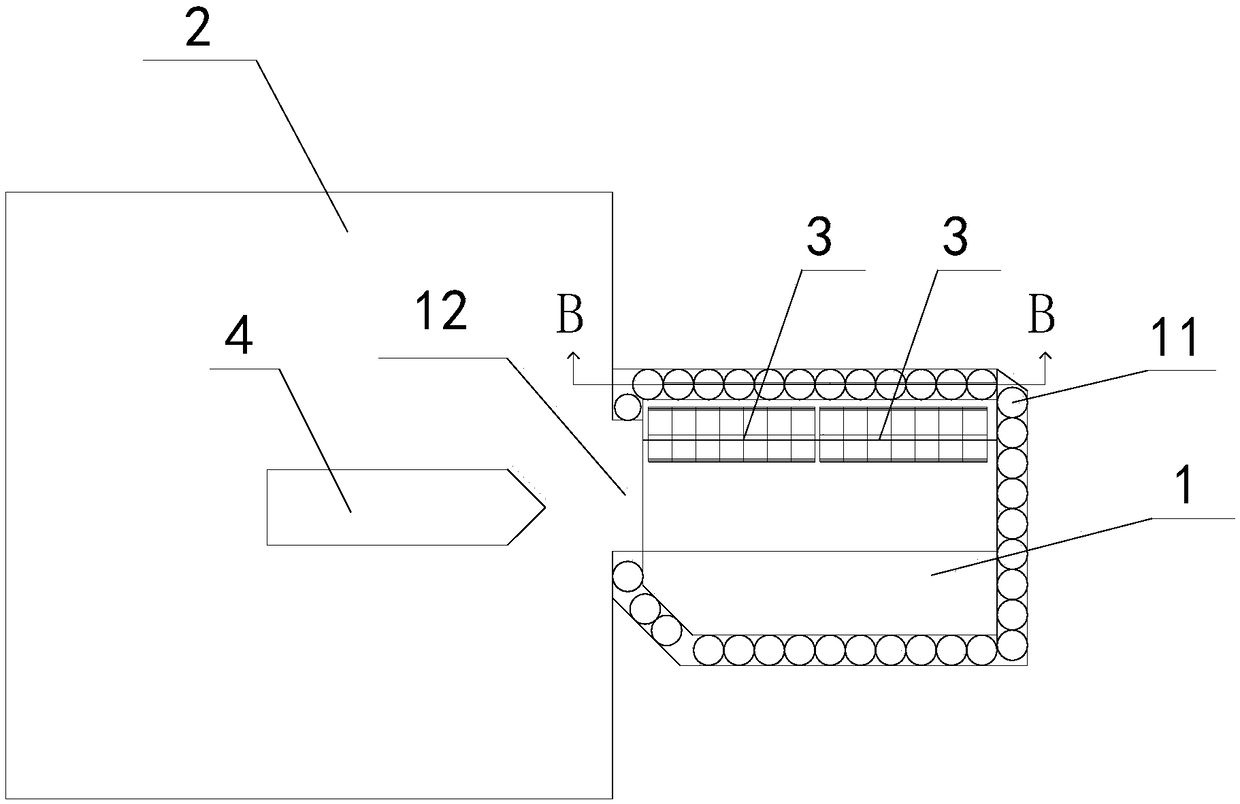

Expendable pattern for manufacturing corner fittings of container and manufacturing method and using method thereof

InactiveCN102029358ACasting high added valueSolution to short lifeFoundry mouldsFoundry coresEngineeringElectrical and Electronics engineering

The invention provides an expendable pattern for manufacturing corner fittings of a container. The expendable pattern comprises a casting latex channel, a first expendable pattern and a second expendable pattern, wherein an expendable pattern latex channel is formed on a side external wall of the first expendable pattern; a first through hole and a plurality of grooves are formed on the first expendable pattern; a second through hole and a third through hole are formed on a wall of the second expendable pattern; a plurality of connecting bumps are formed on the second expandable pattern; the grooves and the connecting bumps are in inserted joint; the expendable pattern latex channel and the casting latex channel are in glued and fixed connection; the casting latex channel is prismatic; the connection position of the grooves and the connecting bumps is provided with gummed paper which is glued and fixed with the first expendable pattern and the second expendable pattern. The process issimple; the expandable pattern has a rational pattern structure, low cost and high production efficiency; and the produced corner fittings of the container have smooth surfaces and low casting defectrate.

Owner:青岛顺联集装箱部件制造有限公司

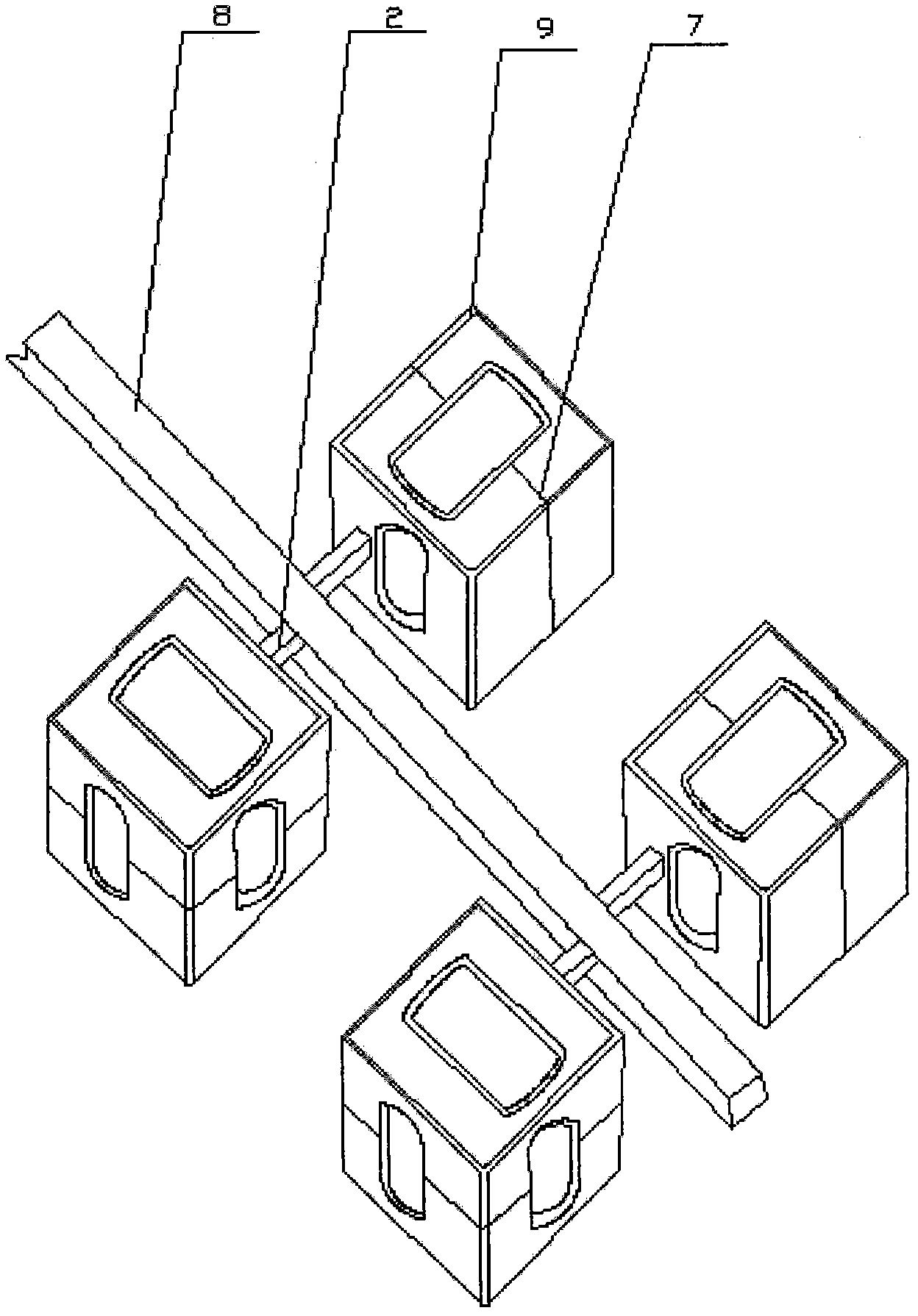

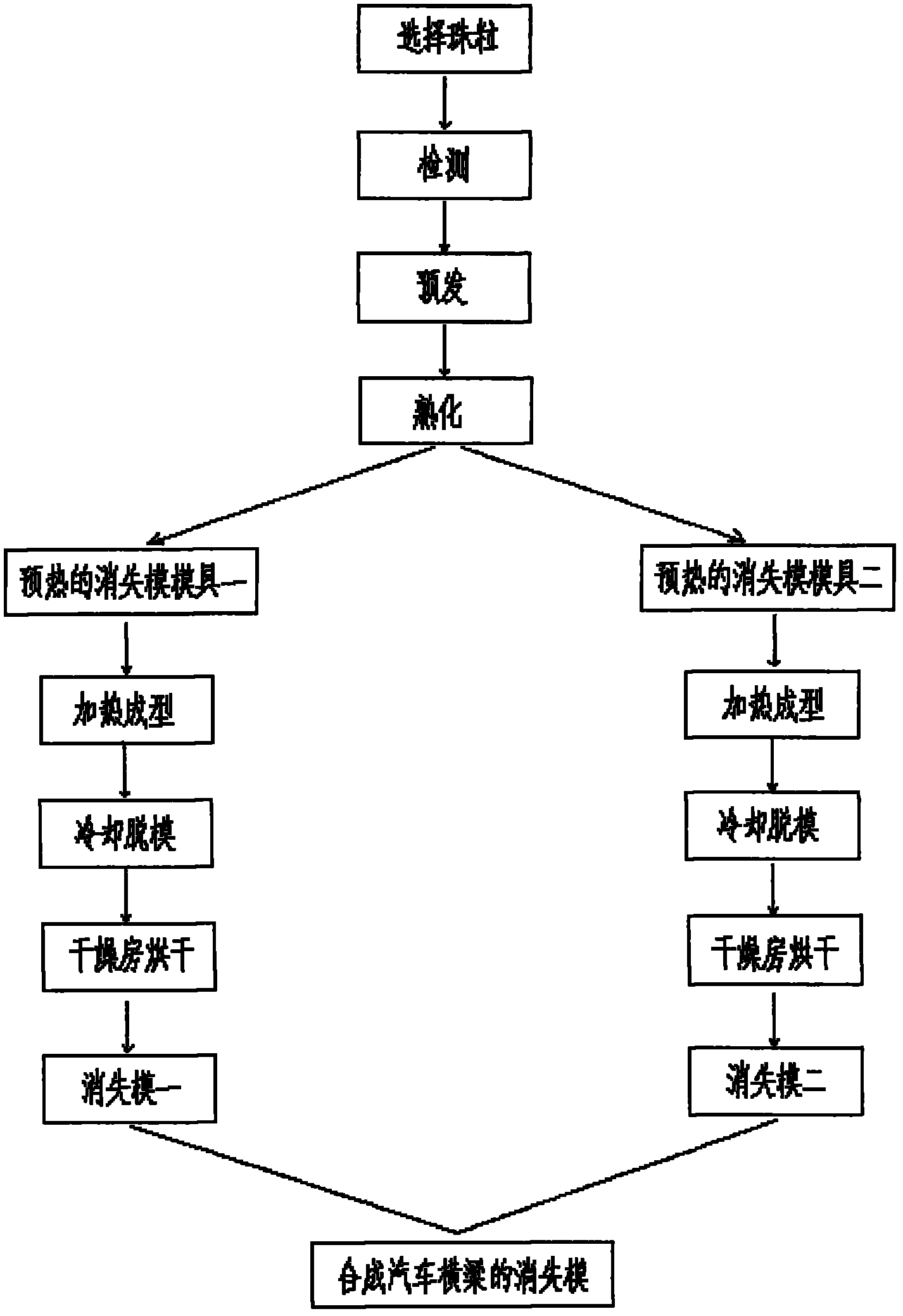

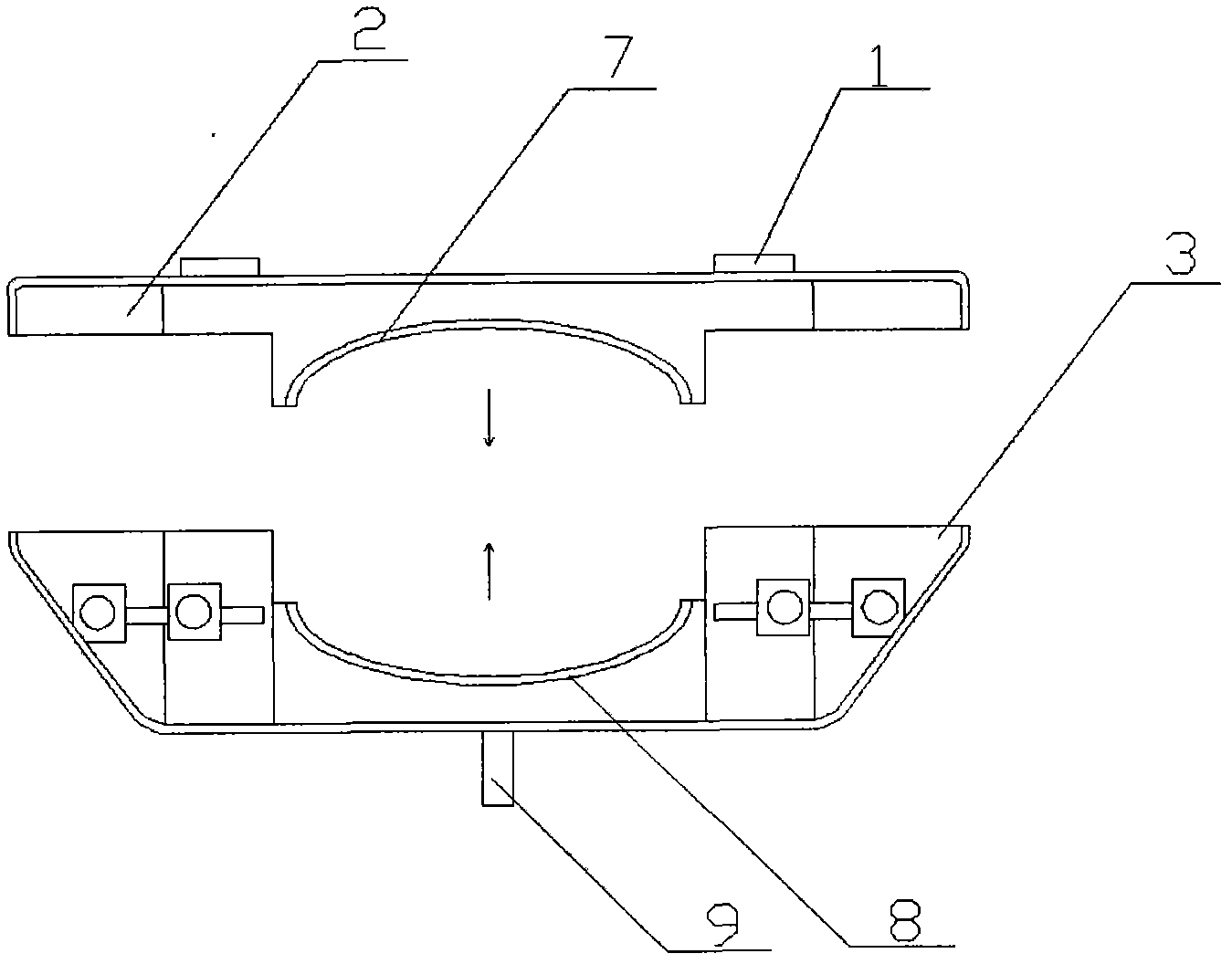

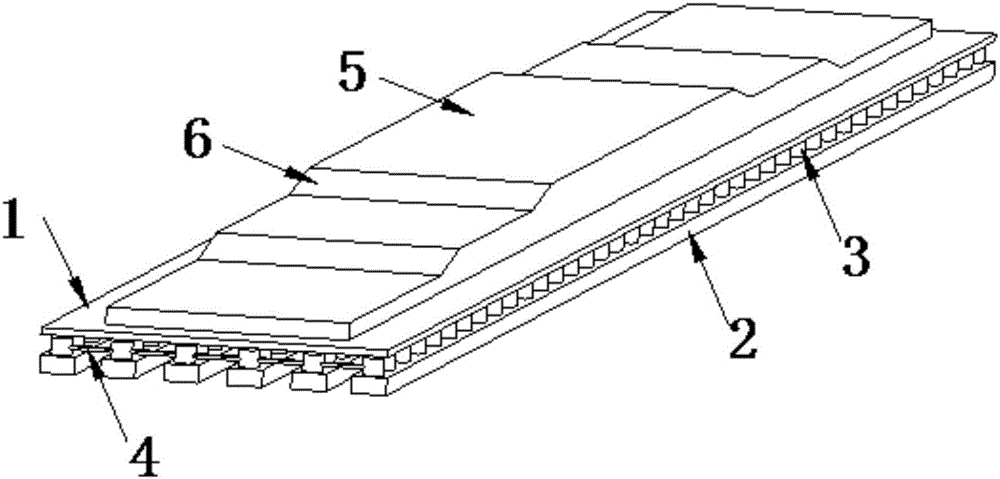

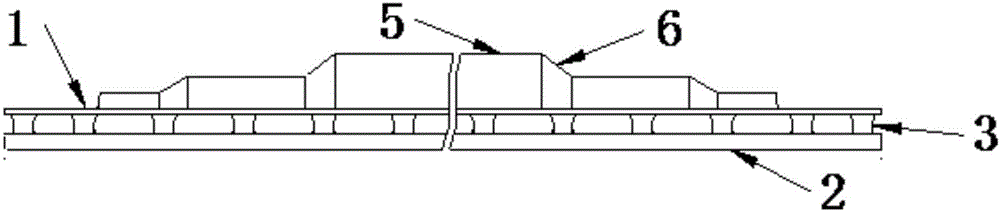

Method for manufacturing automobile cross beam lost foam and using method

InactiveCN102009123ASolution to short lifeReduce or eliminate cleanupFoundry mouldsFoundry coresCasting defectMoisture

The invention provides a method for manufacturing an automobile cross beam lost foam. The method comprises the following steps of: a, selecting proper STMMA beads, and detecting moisture and volatile content of the beads; b, pre-expanding: fully removing the redundant moisture from an intermittent steam pre-expander through a steam-water separation device, and then delivering the STMMA beads intothe intermittent steam pre-expander; c, curing: controlling the curing time of the beads to be between 12 and 48 hours; d, filling the cured beads into a lost foam die, and cooling and molding to obtain a lost foam I and a lost foam II; e, delivering the lost foams into a drying room; and f, inserting and connecting the lost foam I and the lost foam II together to synthesize the automobile cross beam lost foam. The method has simple process; the lost foam die has a reasonable structure; the method has low cost and high production efficiency; and the produced automobile cross beam has smooth surface and low casting defect rate.

Owner:青岛顺联集装箱部件制造有限公司

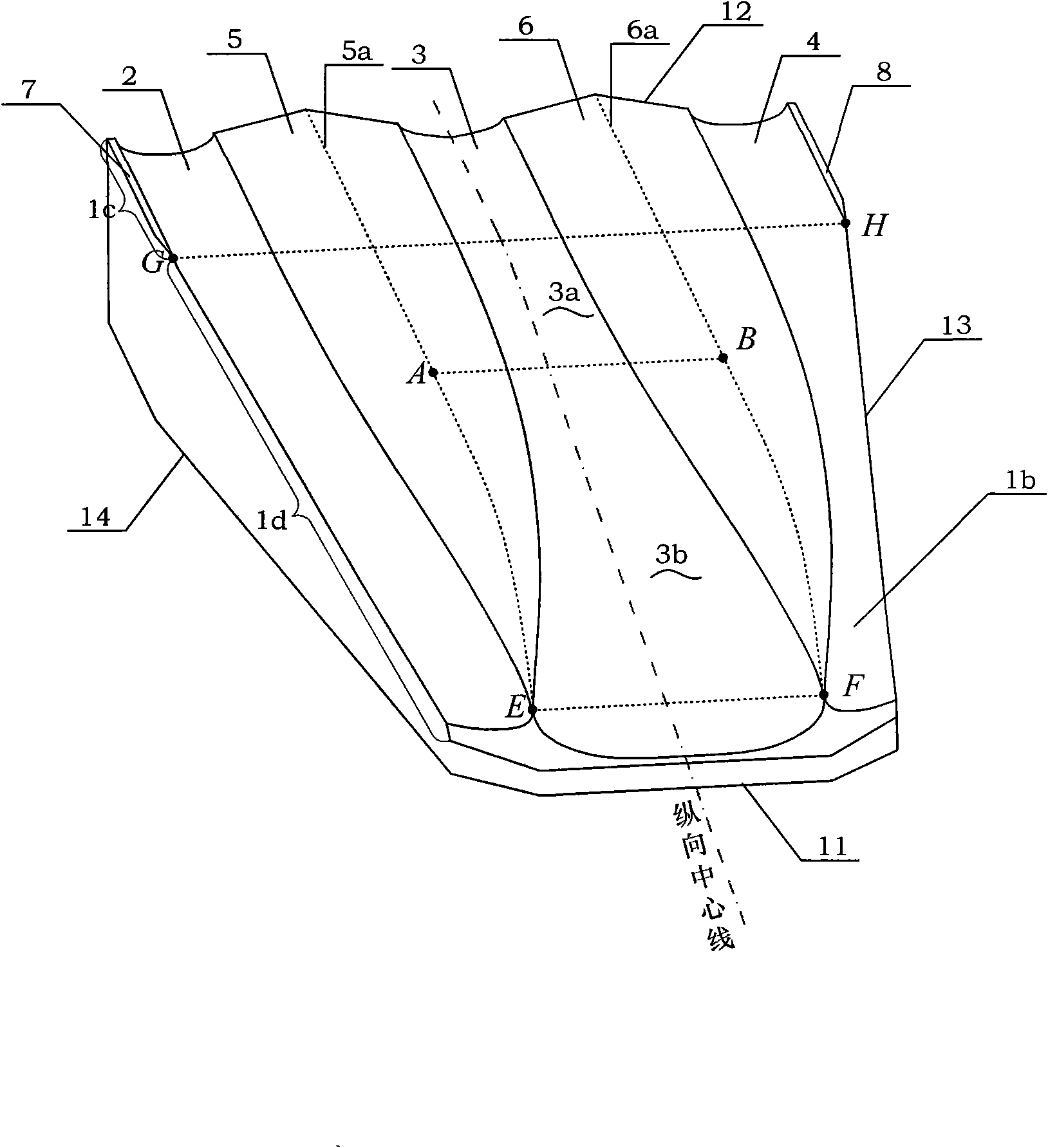

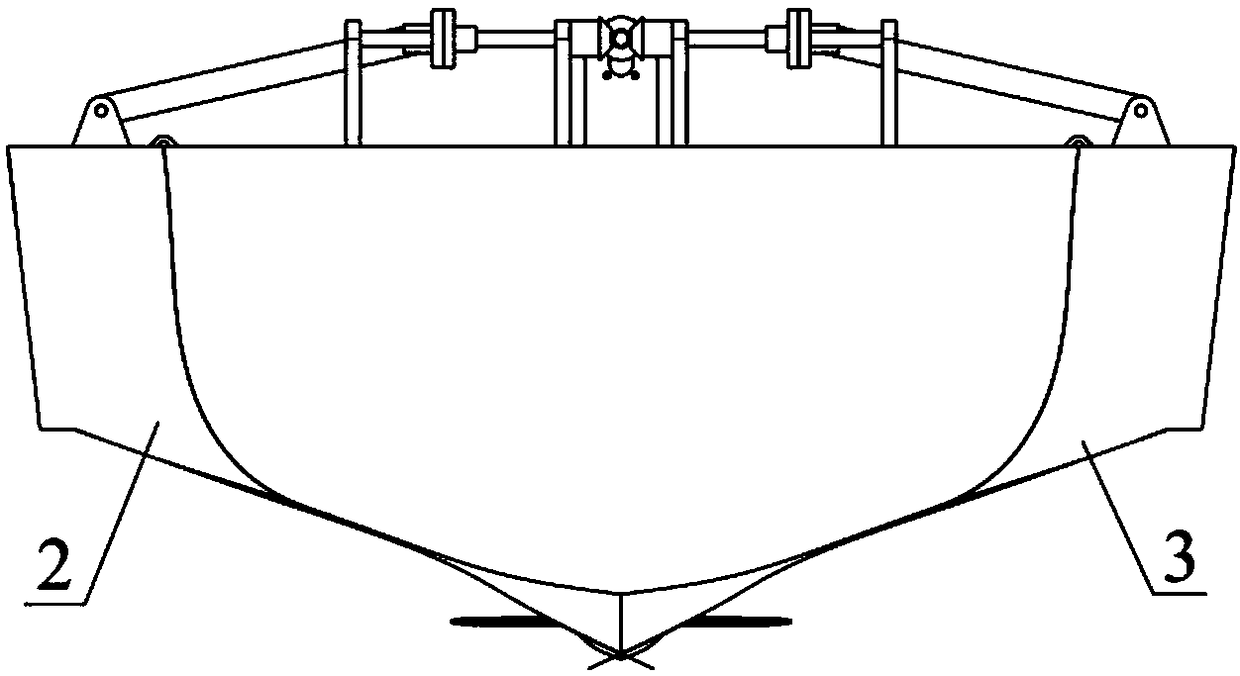

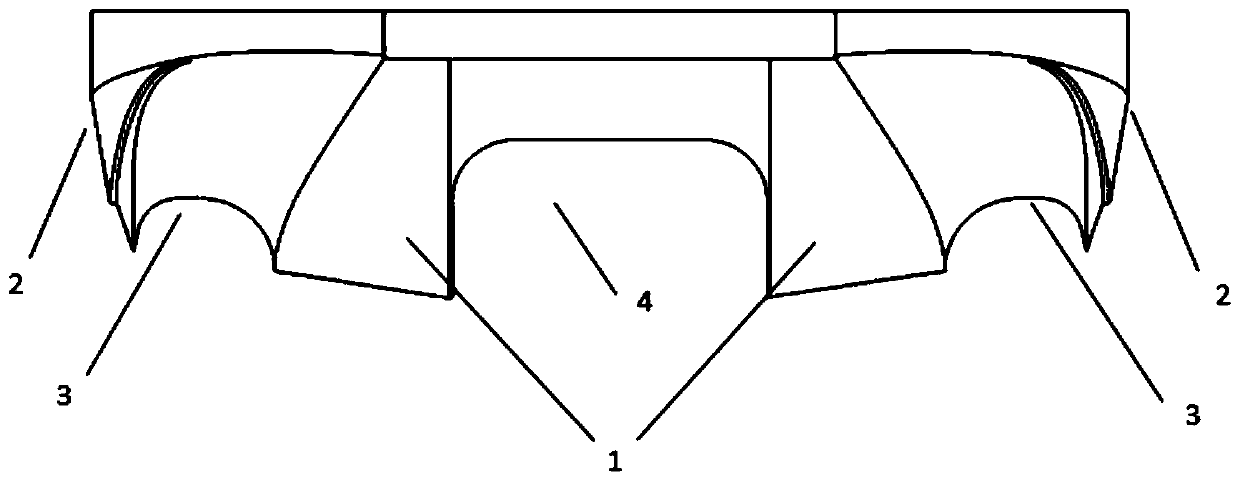

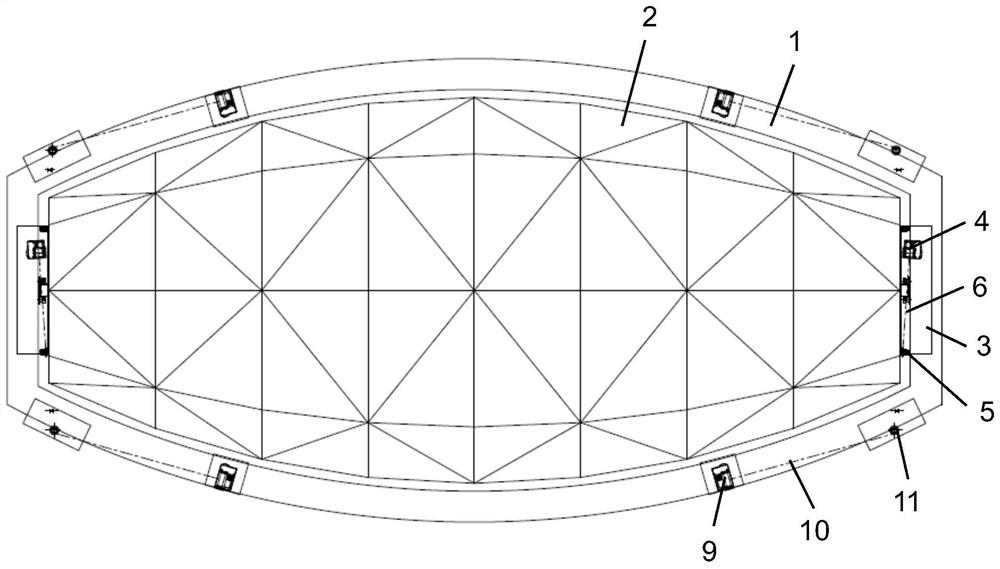

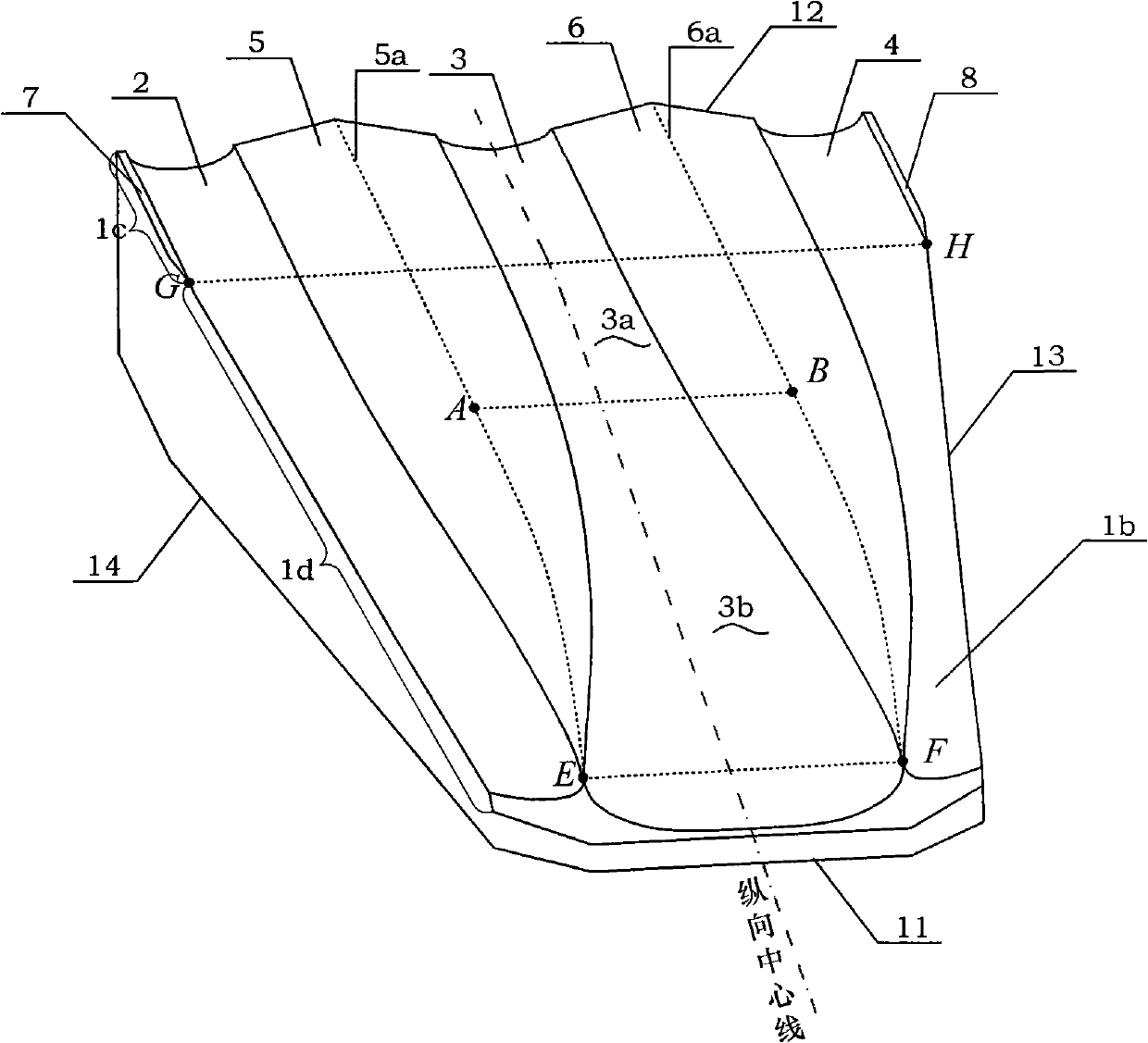

Planing boat with catamaran three-channel hull

InactiveCN101554918AReduced sailing draftSuppressing wavesHull stemsHydrodynamic/hydrostatic featuresStress concentrationStress Problem

The invention discloses a planing boat with a catamaran three-channel hull. The planing boat is provided with a hull and a board at least. The bottom of the hull is provided with an A trunk bulkhead end surface, a B trunk bulkhead end surface, an A slideway, a B slideway, a C slideway, an A planing surface and a B planing surface; the B slideway is arranged along a central line and is a sector structure; the A planing surface and the B planing surface are arranged at two sides of the B slideway; the A slideway is arranged between the A planing surface and a right trunk bulkhead which is provided with the A trunk bulkhead end surface at the stern; and the C slideway is arranged between the B planing surface and a left trunk bulkhead which is provided with the B trunk bulkhead end surface at the stern. The catamaran three-channel hull adopts oval channel section conformation to solve the concentrative stress problem of the hull effectively.simultaneously, on the basis of common channel planing boats, the invention adds two outer side channels at two sides of the stern and changes single channel type into three-channel type, thus greatly increasing the width of the stern, not only improving the effective use area of the board, but also enhancing the transversal stability of the planing boat and being capable of reducing the wave making of the boat.

Owner:BEIHANG UNIV

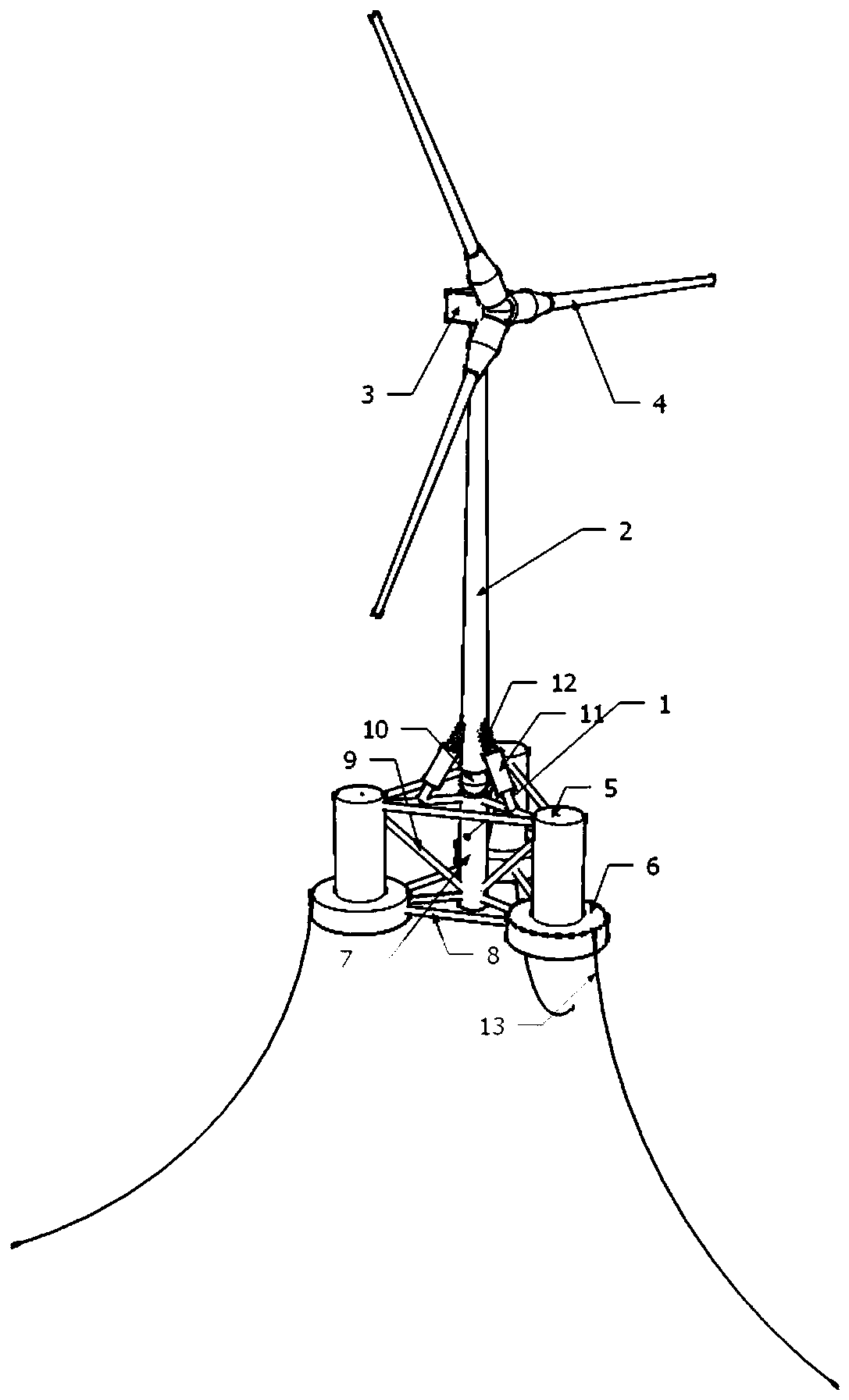

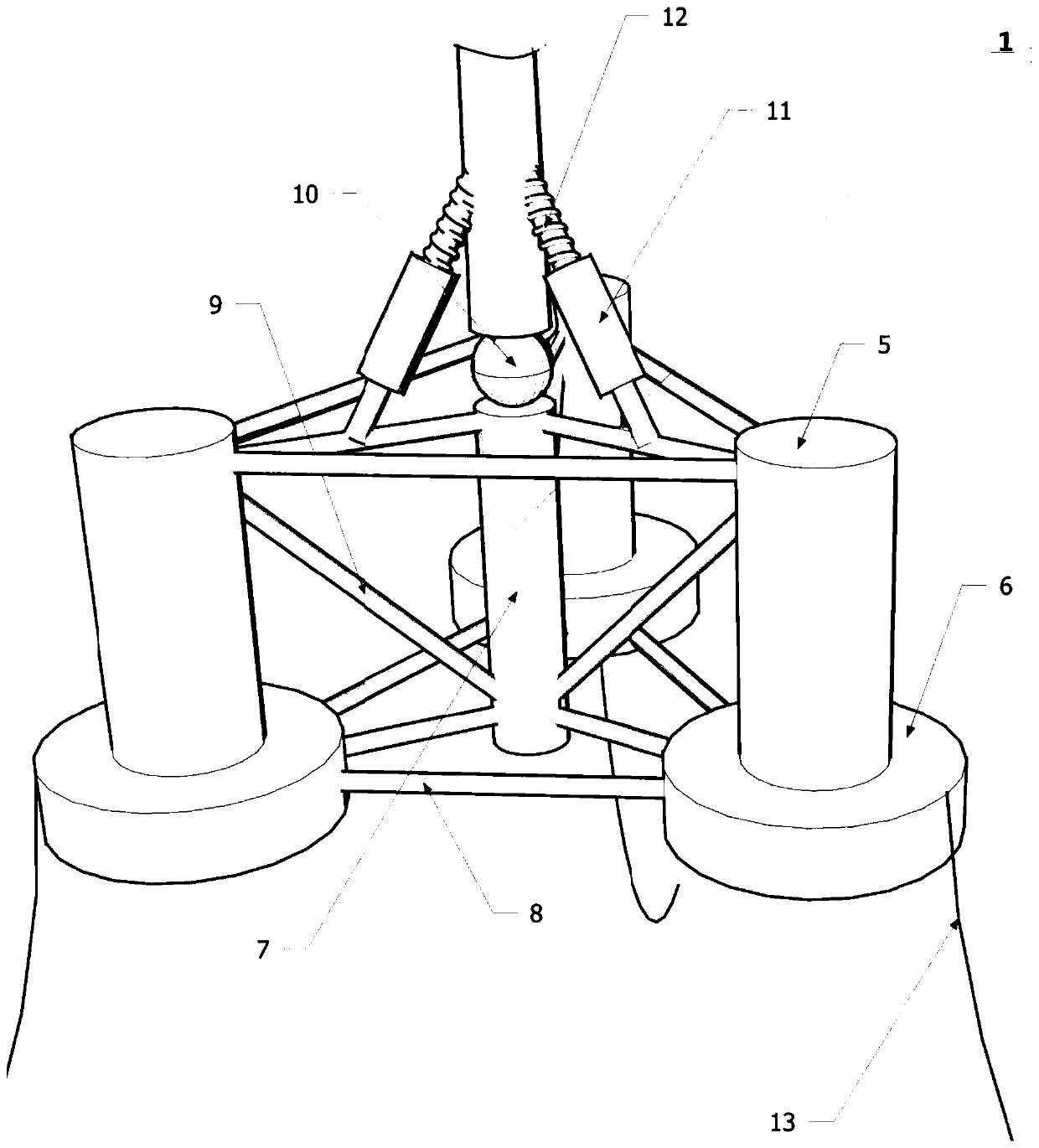

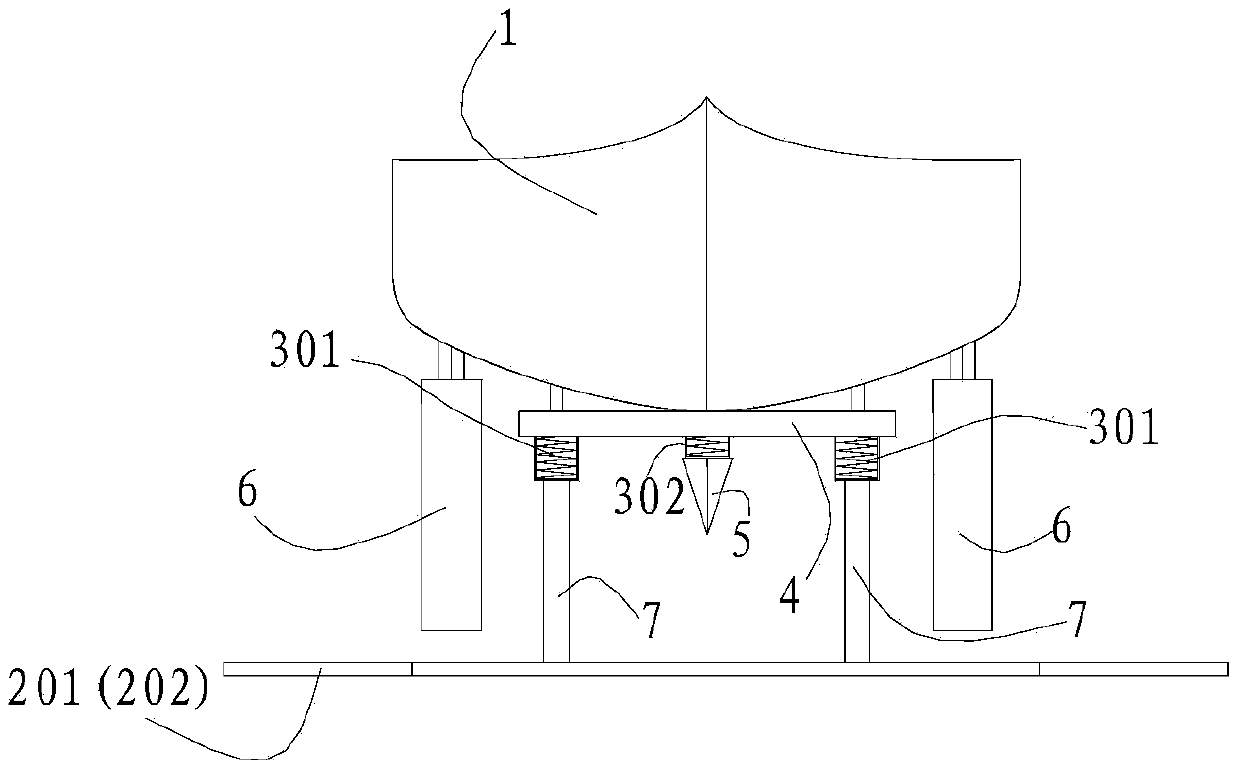

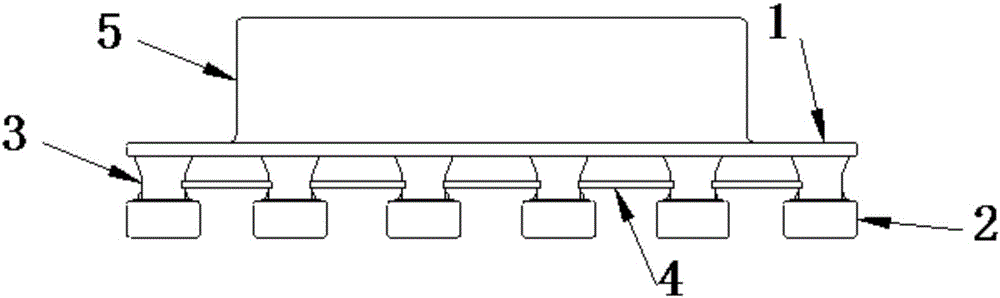

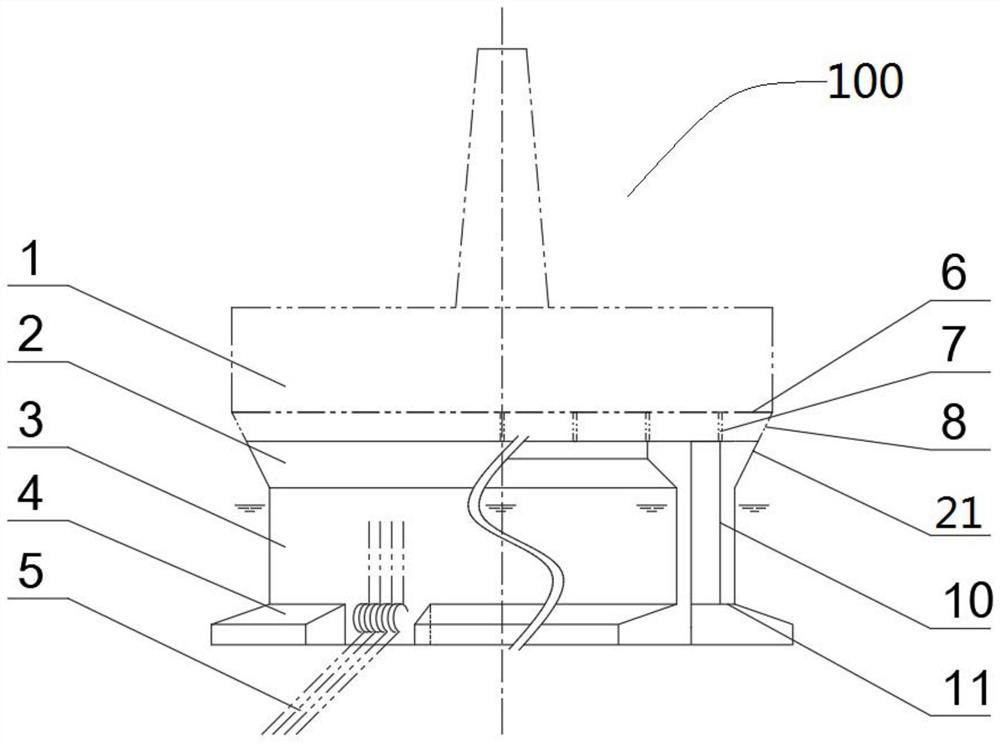

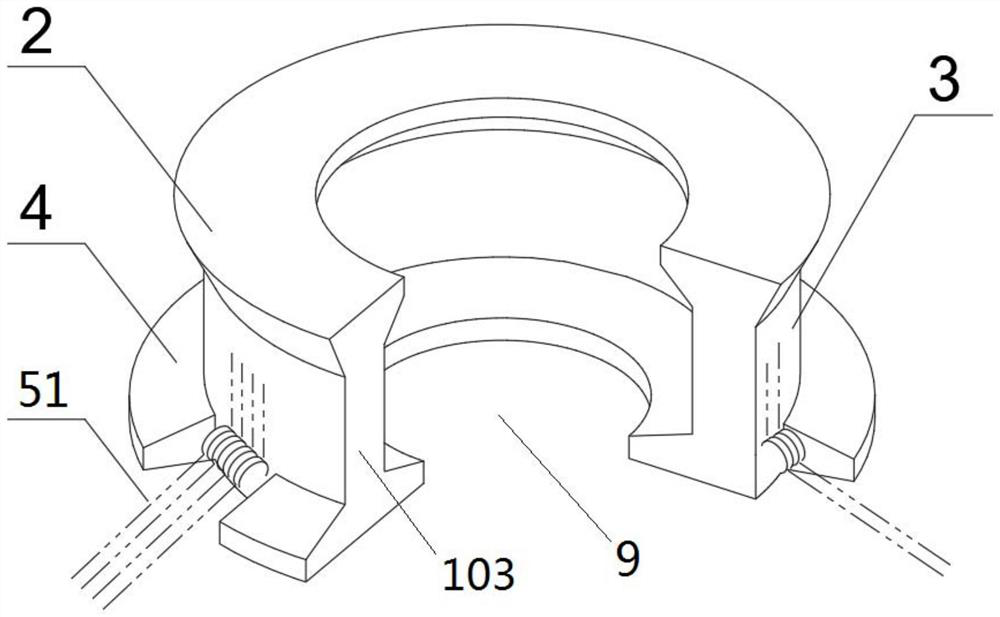

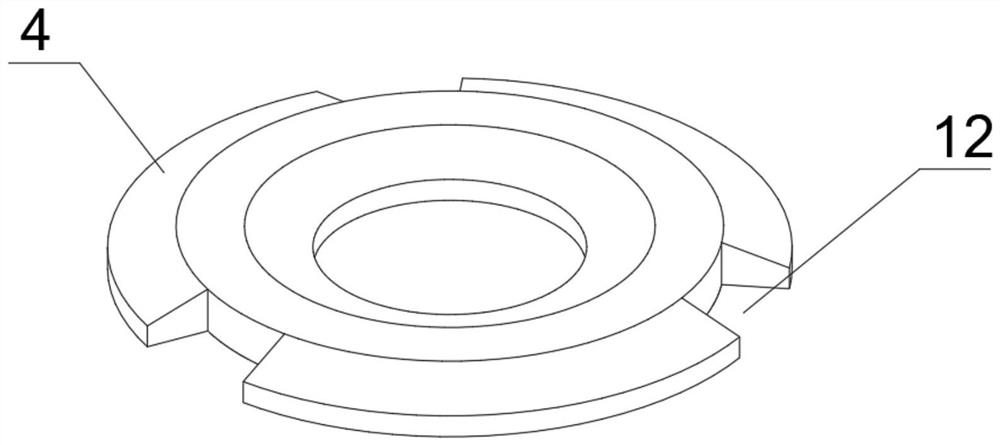

Semi-submersible wind power generator platform with vibration reduction and isolation function

InactiveCN110182326ASmall range of motionLow maintenanceWaterborne vesselsEngine fuctionsEngineeringSnubber

The invention belongs to the related technical field of floating offshore wind power generators, and discloses a semi-submersible wind power generator platform with a vibration reduction and isolationfunction. The semi-submersible wind power generator platform comprises a supporting structure, a vibration reduction and damping assembly and a spherical hinge, wherein the supporting structure is ofan upper layer and a lower layer frame structure, and the upper layer of the supporting structure is connected with a generator assembly through the spherical hinge; the vibration reduction and damping assembly is connected with the generator assembly and the supporting structure, and is used for reducing vibration suffered by the generator assembly; the vibration reduction and damping assembly comprises a plurality of dampers and a plurality of springs, wherein the dampers are uniformly distributed around the generator assembly; and one ends of the dampers are connected to the supporting structure, and the other ends of the dampers are connected to the generator assembly through the springs. According to the semi-submersible wind power generator platform, the motion amplitude of an offshore wind power generator is can obviously reduced, so that the stability of the whole generator platform is increased, and a safe and reliable platform supporting infrastructure is provided for high-power floating offshore wind power generation equipment.

Owner:HUAZHONG UNIV OF SCI & TECH

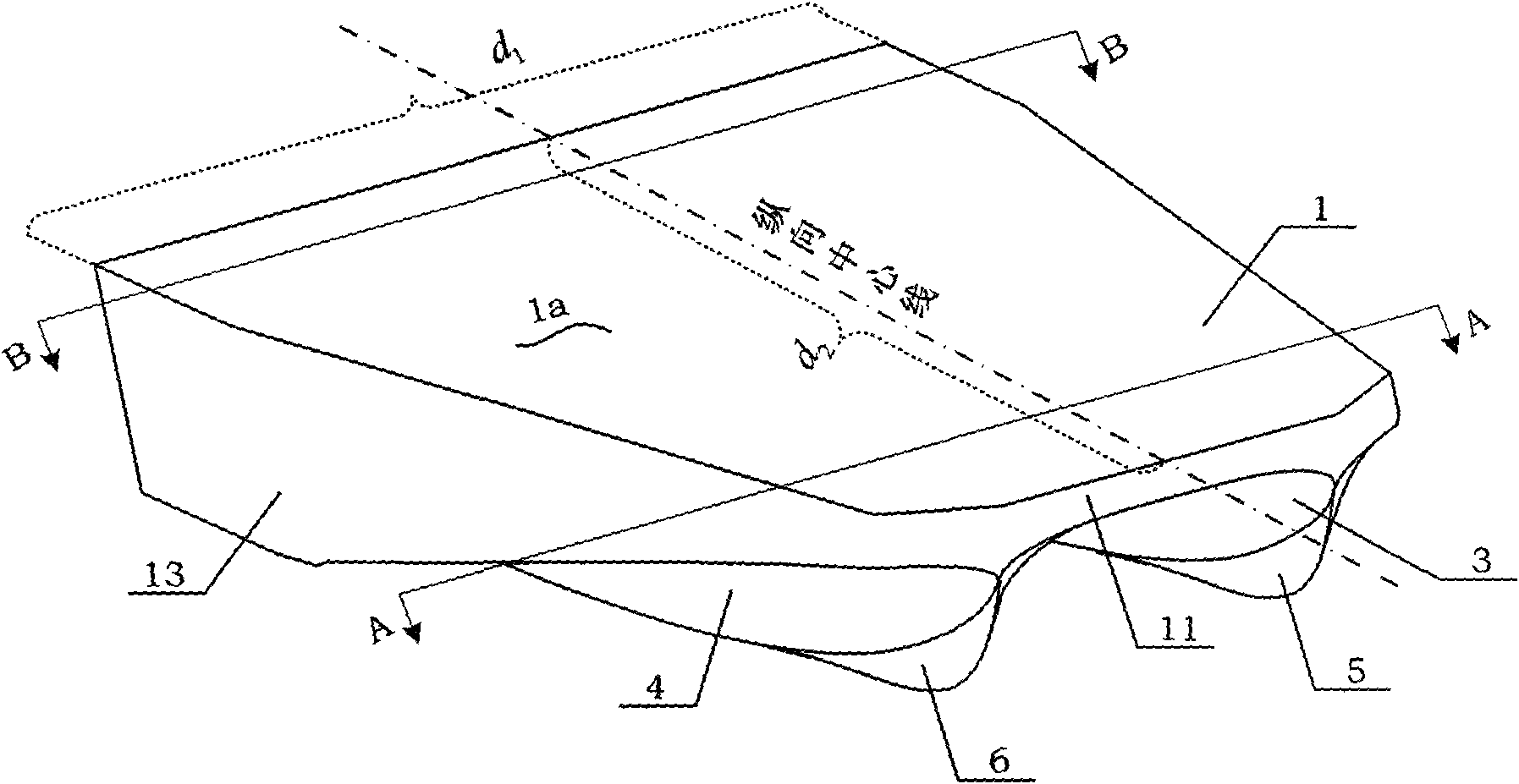

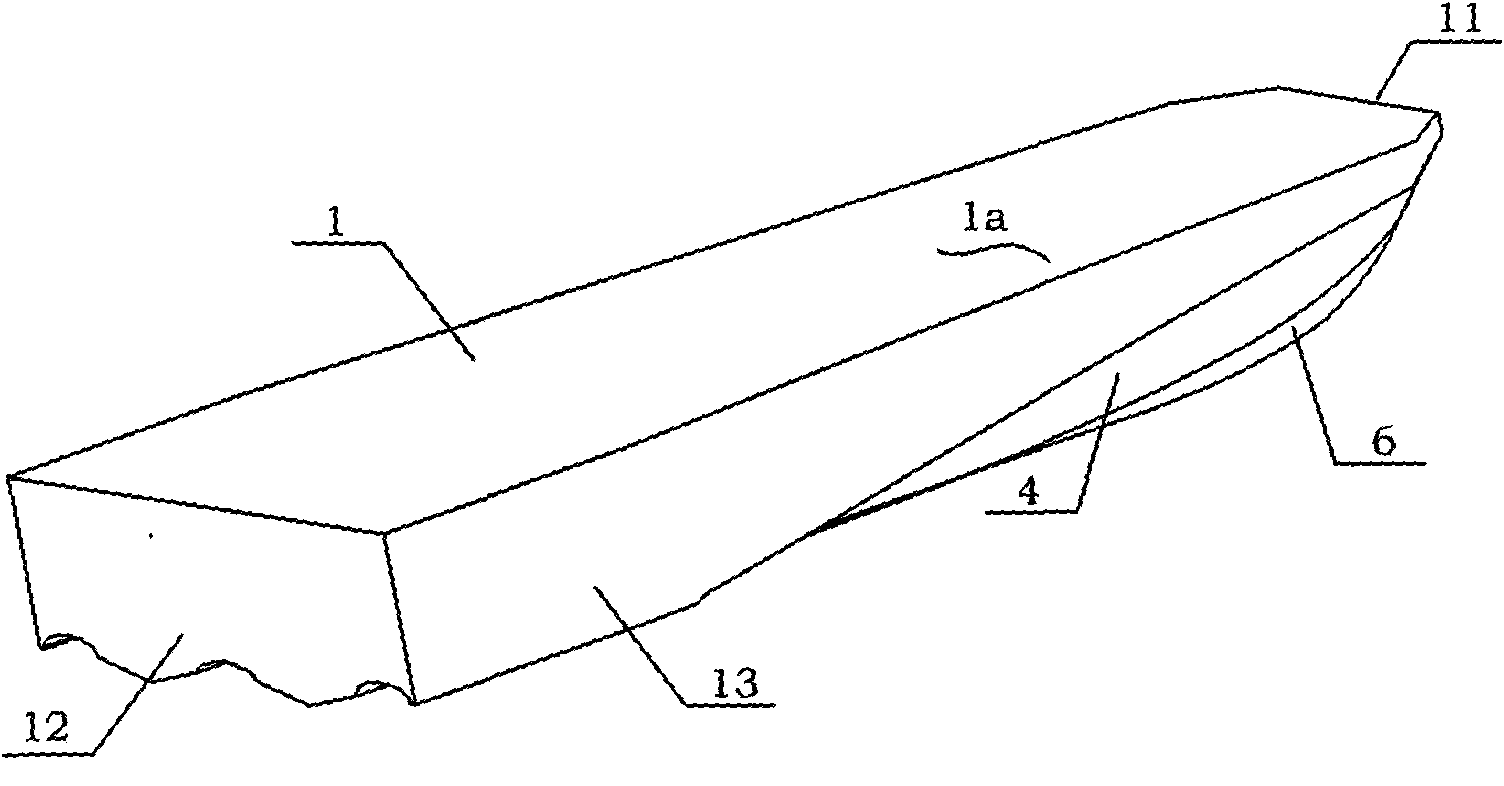

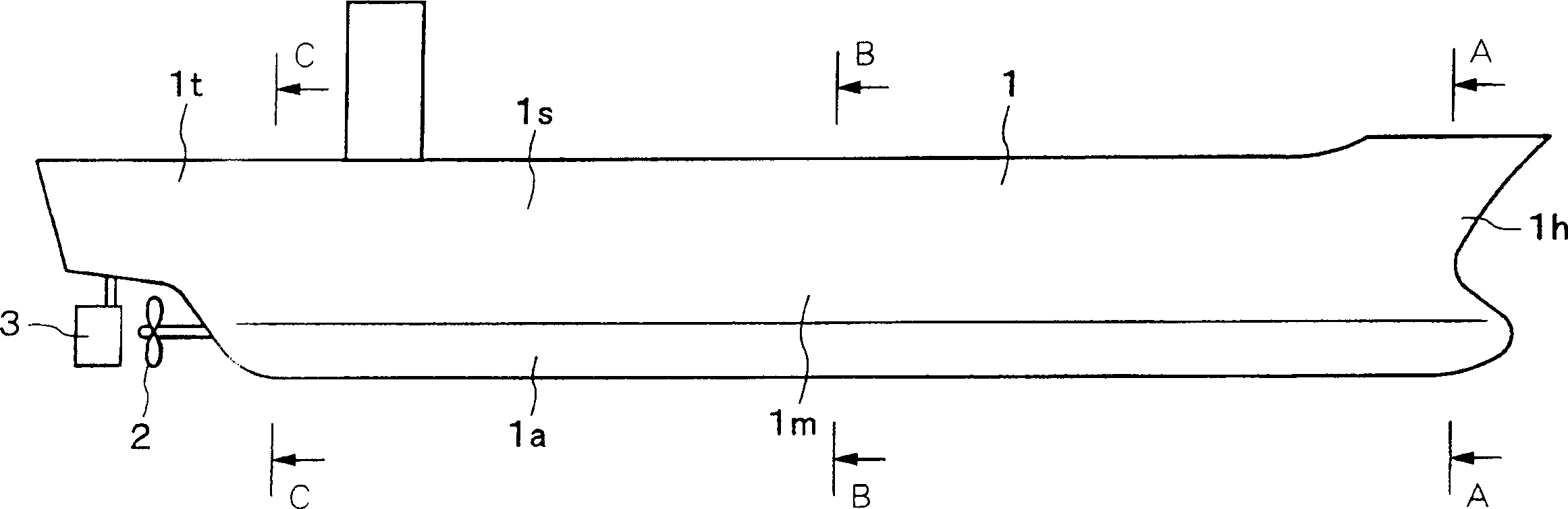

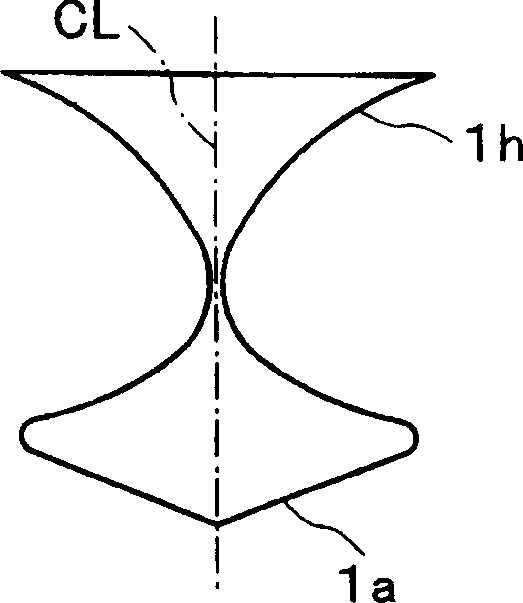

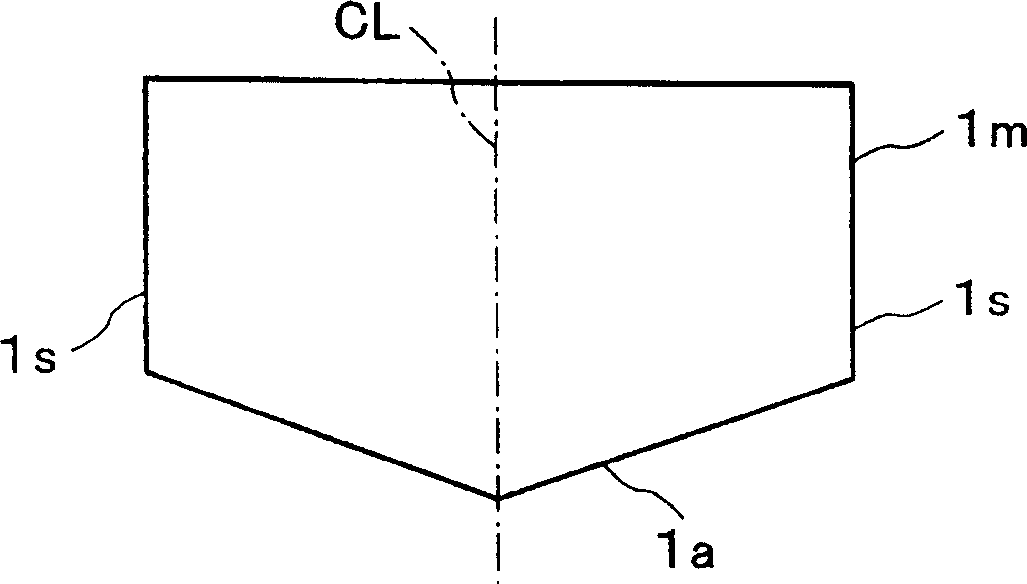

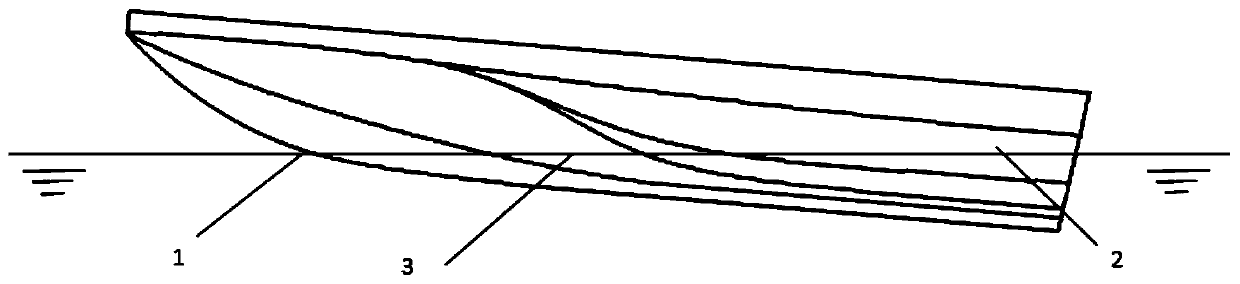

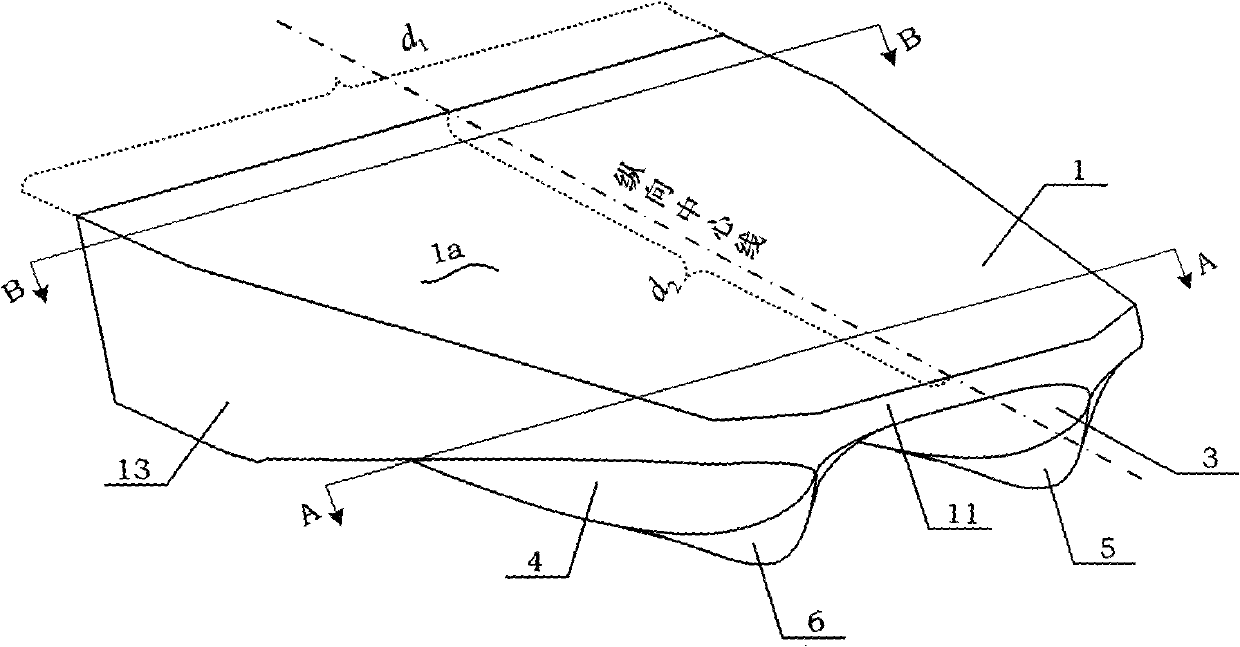

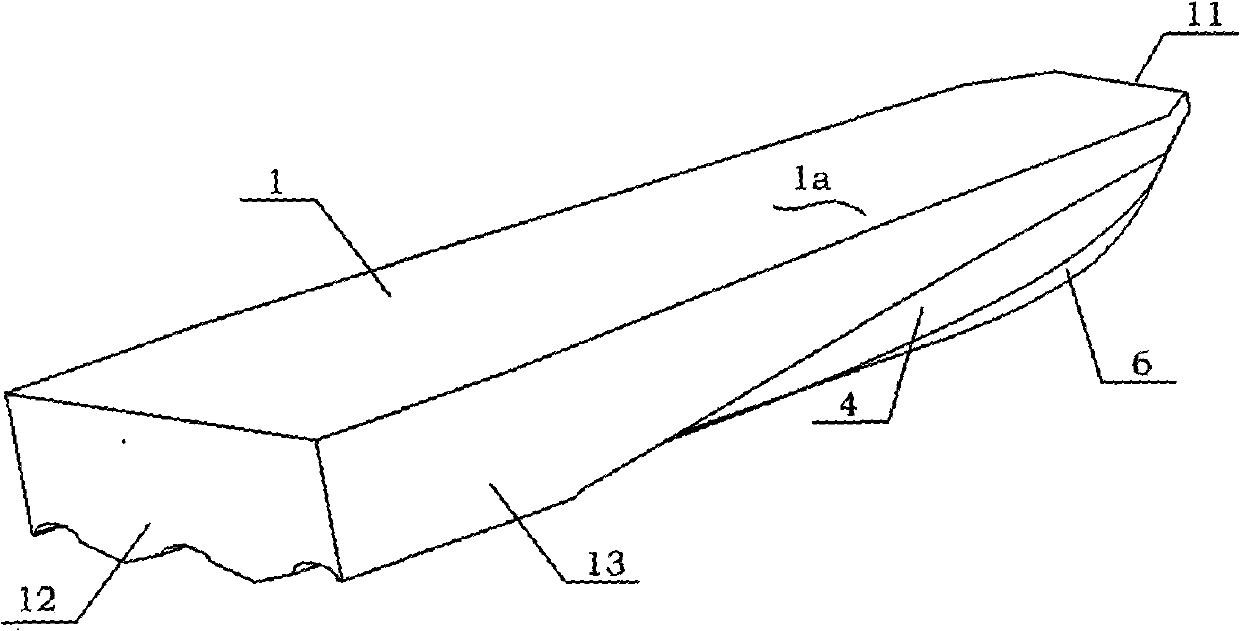

Large transport ship

The present invention provides a large transport ship in which the shape of a ship bottom 1a from a bow 1h to a stem 1t, when viewed on a cross-section perpendicular to the longitudinal direction of the ship bottom 1a, is tapered towards the center CL of the ship bottom in the widthwise direction. Consequently, it is possible to resolve problems associated with changes in the draft corresponding to the state of the load, without using ballast water.

Owner:SHIPBUILDING RES CENT OF JAPAN

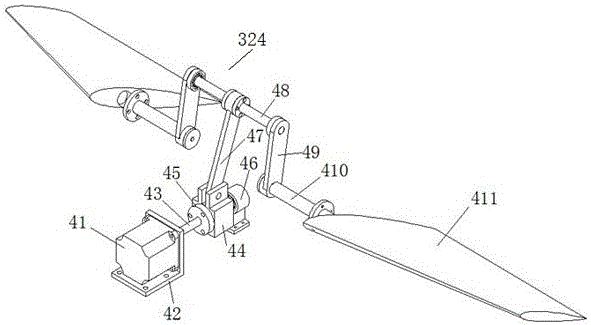

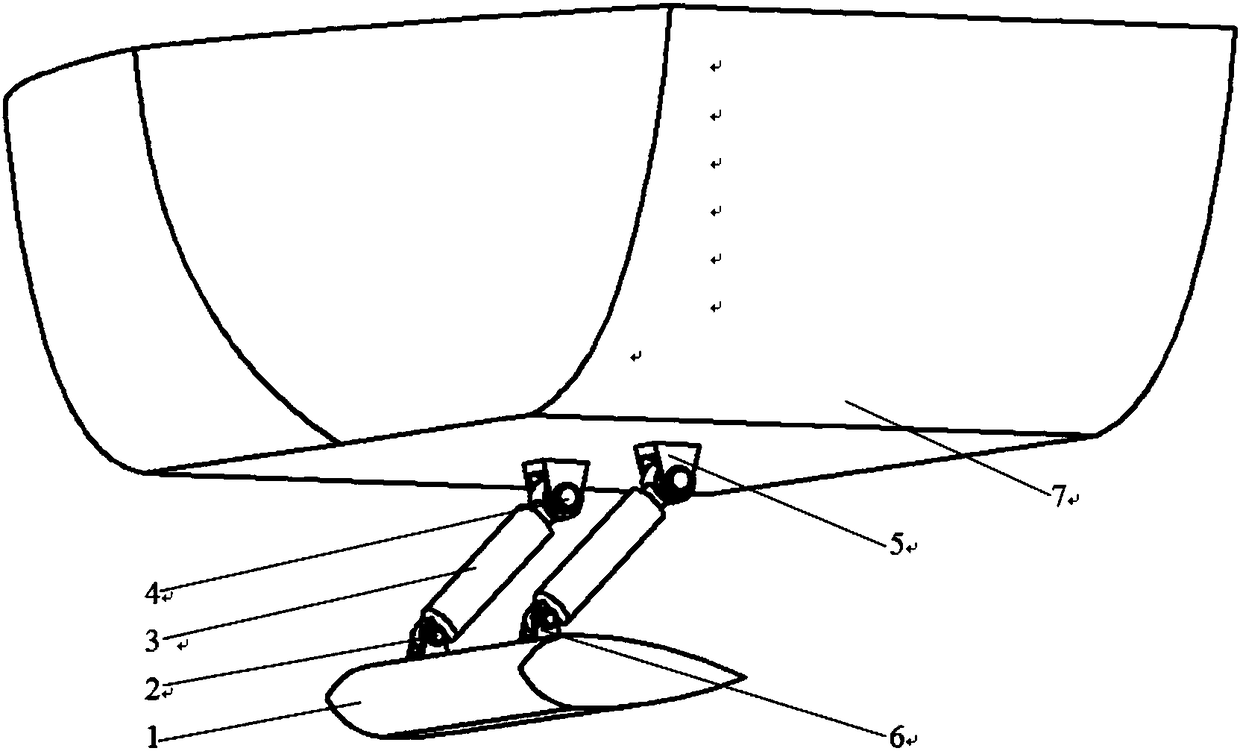

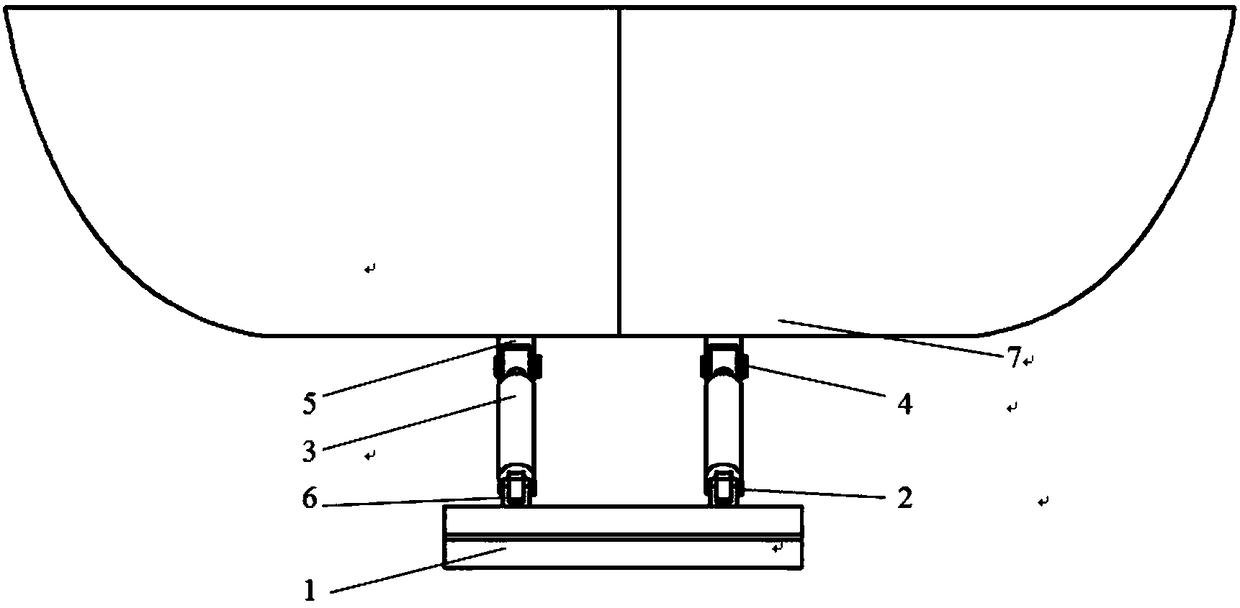

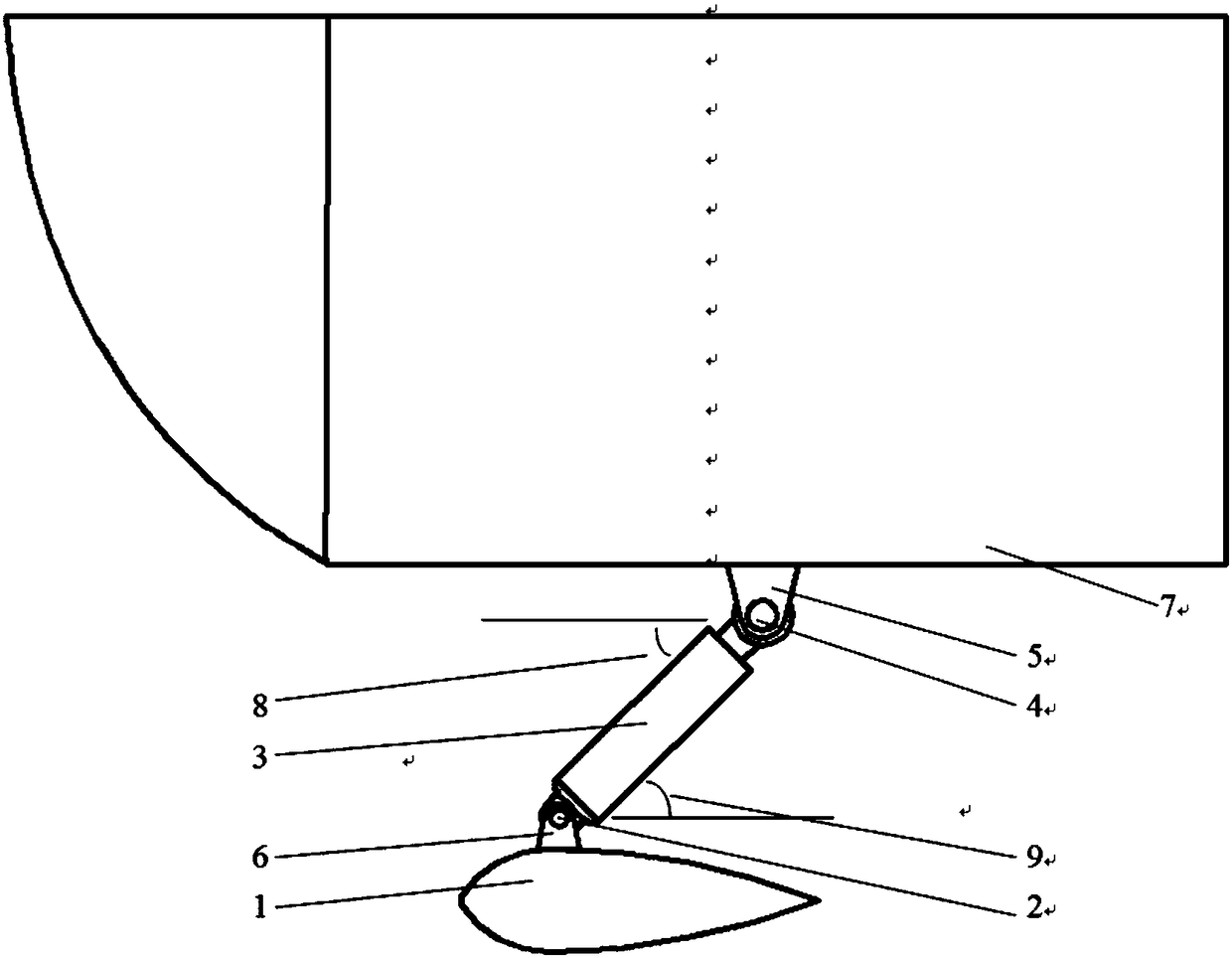

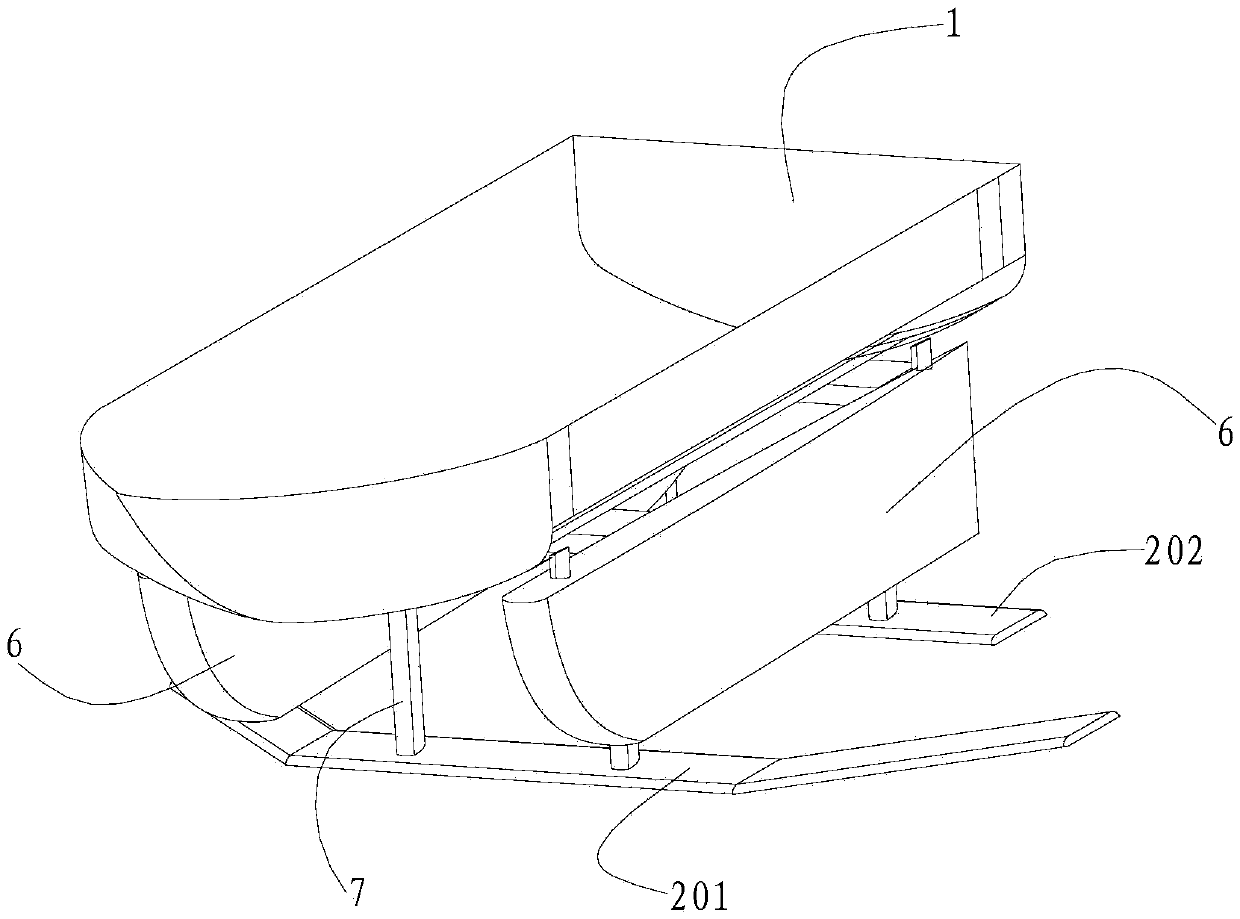

Marine adjustable hydrofoil device

InactiveCN108482575ASmall draftReduce resistanceHydrodynamic/hydrostatic featuresHydraulic cylinderEngineering

The invention provides a marine adjustable hydrofoil device. The marine adjustable hydrofoil device comprises a hull, a hydrofoil, a first hydraulic cylinder and a second hydraulic cylinder. A first hinge support and a second hinge support are fixed to the lower part of the hull, and a third hinge support and a fourth hinge support are fixed to the upper part of the hull. The top end of the firsthydraulic cylinder is connected with the first hinge support through a first rotating shaft, and the bottom end of the first hydraulic cylinder is connected with the third hinge support through a second rotating shaft. The top end of the second hydraulic cylinder is connected with the second hinge support through a third rotating shaft, and the bottom end of the second hydraulic cylinder is connected with the fourth hinge support through a fourth rotating shaft. The marine adjustable hydrofoil device can enable a ship installing the same to control the distance between the hydrofoil and the bottom of the ship and the angle of attack of the hydrofoil under different speed conditions, so as to reduce the draught of the ship and reduce the resistance of the ship in the sailing process to achieve the goal of energy saving and emission reduction.

Owner:HARBIN ENG UNIV

Hull structure with underwater appendage

InactiveCN105365998AReduce shockImprove seakeepingHydrodynamic/hydrostatic featuresHull structureMarine engineering

A hull structure with an underwater appendage comprises an underwater appendage structure arranged below the hull; a suspension is arranged between the underwater appendage structure and the hull; the hull structure arranges the suspension between the hull and the underwater appendage structure so as to buffer the wave impact load on the underwater appendage structure; the suspension can attenuate impact vibrations, can weaken refloating motions caused by posture adjustment, and comprises an elastic piece, a damper and a guide mechanism respectively providing buffering, damping and force transmission effects; the underwater appendage structure receives the impact transferred by the waves; the guide mechanism transfers force and moment between the underwater appendage structure and the bottom of the hull; the elastic piece can be deformed; the damper can provide damping effect for the elastic piece so as to prevent the elastic piece from swinging back and forth, so the impact on the bottom of the hull can be greatly reduced, thus improving hull sea-keeping, and improving passenger comfort level on the hull.

Owner:INST OF IND TECH GUANGZHOU & CHINESE ACADEMY OF SCI

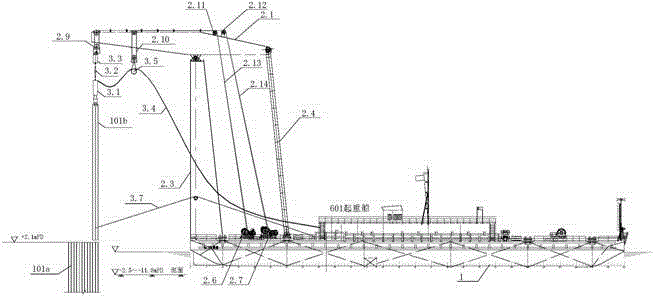

Construction process for shipping large sinking pipes by self-propelled semi-submerged ship

ActiveCN106522275AReduce distanceImprove work efficiencyArtificial islandsUnderwater structuresWork productivityPrefabrication

The invention provides a construction process for shipping large sinking pipes by a self-propelled semi-submerged ship for transporting the sinking pipes from a sinking pipe prefabrication factory to a foundation trench region for sinking pipe mounting construction. A mooring and outfitting region is arranged next to the foundation trench region, the semi-submerged ship loads the sinking pipes in a deep dock of the sinking pipe prefabrication factory and transports the same to the mooring and outfitting region, and after an outfitting step of the sinking pipes in the mooring and outfitting region is finished, the sinking pipes are transported to the foundation trench region in a floating manner through a sinking pipe mounting ship and a tug. According to the construction process for shipping large sinking pipes by the self-propelled semi-submerged ship provided by the invention, the floating transportation distance of the sinking pipe is greatly reduced, and the work efficiency of transporting the sinking pipe to 3-4 times; secondly, as draft of the semi-submerged ship which transports the sinking pipes is smaller compared with that of sinking pipe floating transportation in the prior art, the requirement on channel depth is greatly reduced. The channel needs not to be excavated, so that the time and economical costs are further saved; furthermore, the requirements on natural conditions such as a water wave flow by transporting the sinking pipes by the semi-submerged ship are relatively low, the limiting condition of transporting the sinking pipes is reduced, and the work efficiency of transporting the sinking pipes is further improved.

Owner:NO 2 ENG CO LTD OF CCCC FIRST HARBOR ENG +1

Ultra-large type multi-floating-body semi-submersible floating platform

Owner:DALIAN UNIV OF TECH

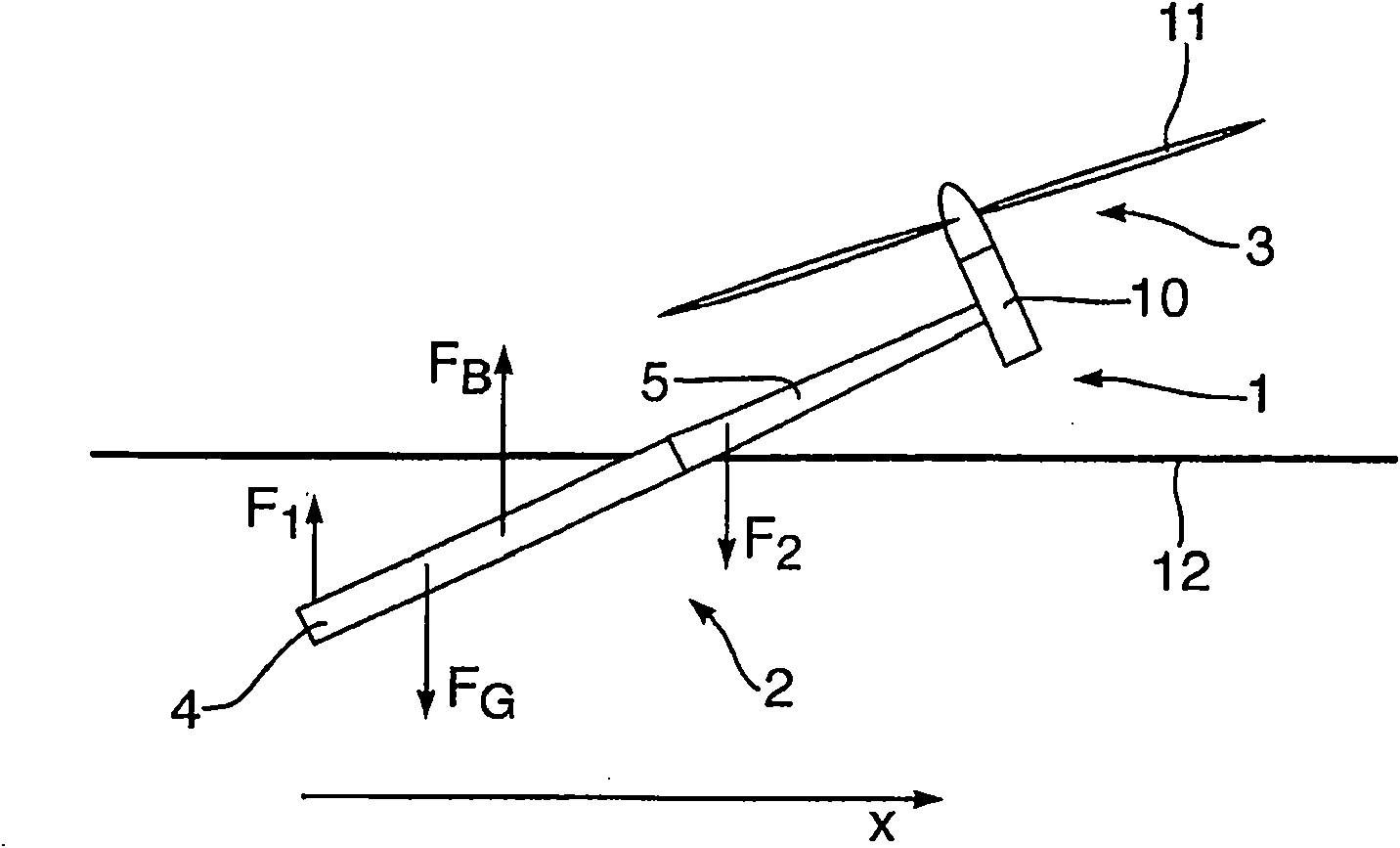

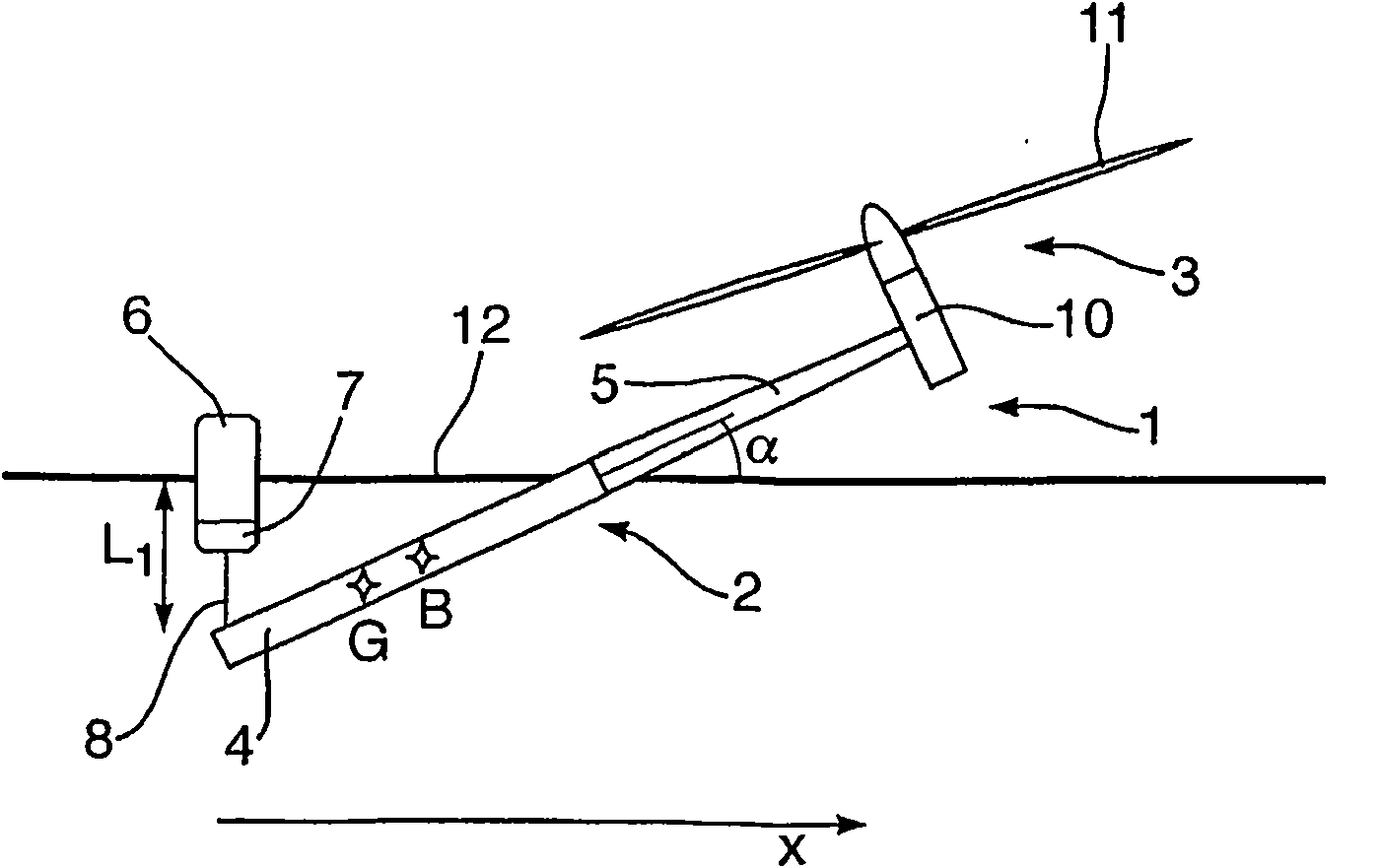

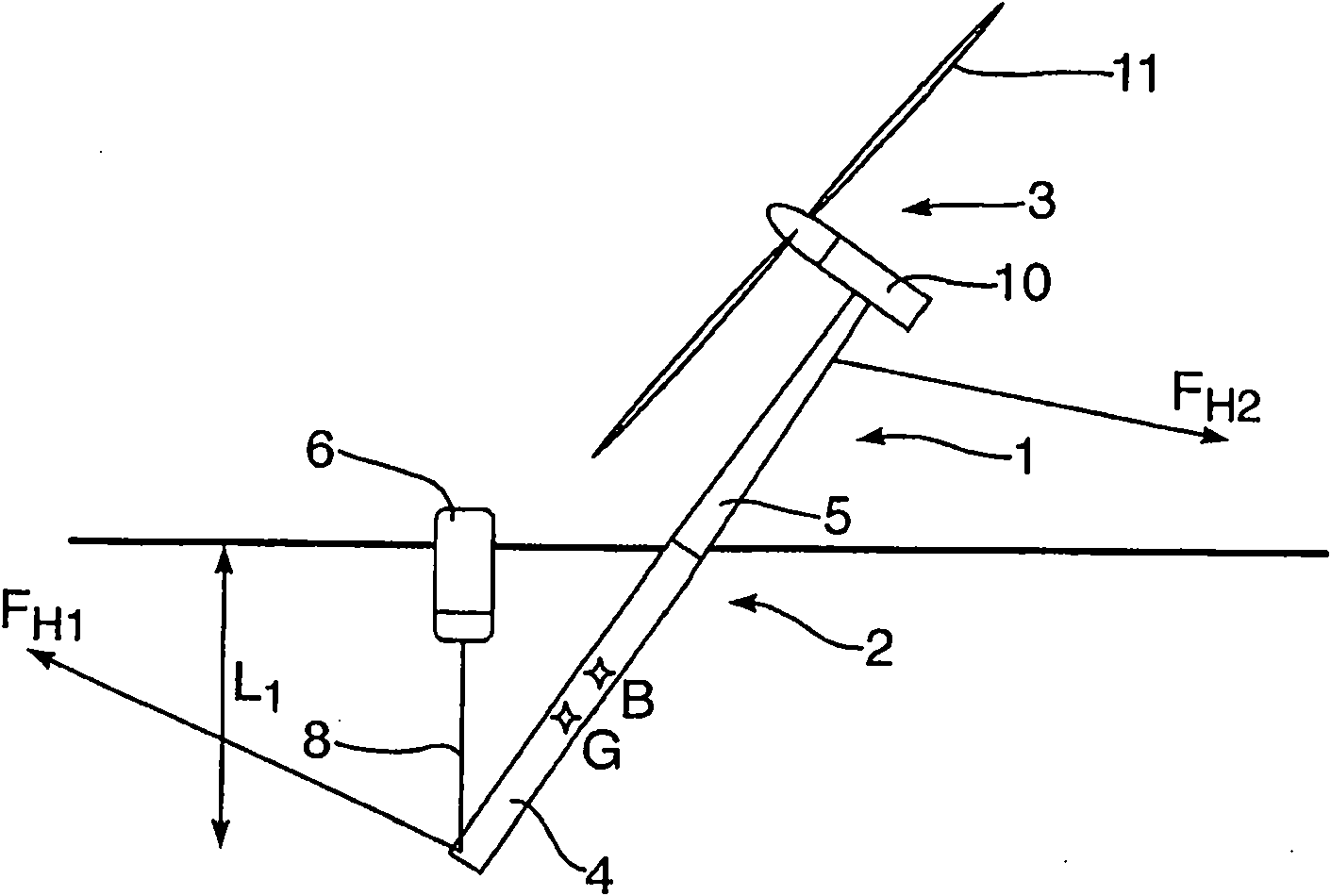

Method and apparatus for towing offshore wind turbines

ActiveCN102171446AIncrease the number ofSmall draftWaterborne vesselsWind motor assemblyNacelleMarine engineering

A method of moving a floating wind turbine (1) relative to a body of water, the floating wind turbine (1) having a buoyant body with a nacelle at the upper end thereof. The method comprises floating the floating wind turbine (1) in the body of water, and towing the floating wind turbine (1) whilst holding the buoyant body in an inclined position, whereby the nacelle is held clear of the water. As the wind turbine (1) is held in an inclined position, it can be towed through regions of shallower water than if it were in a vertical position.

Owner:海维德公司

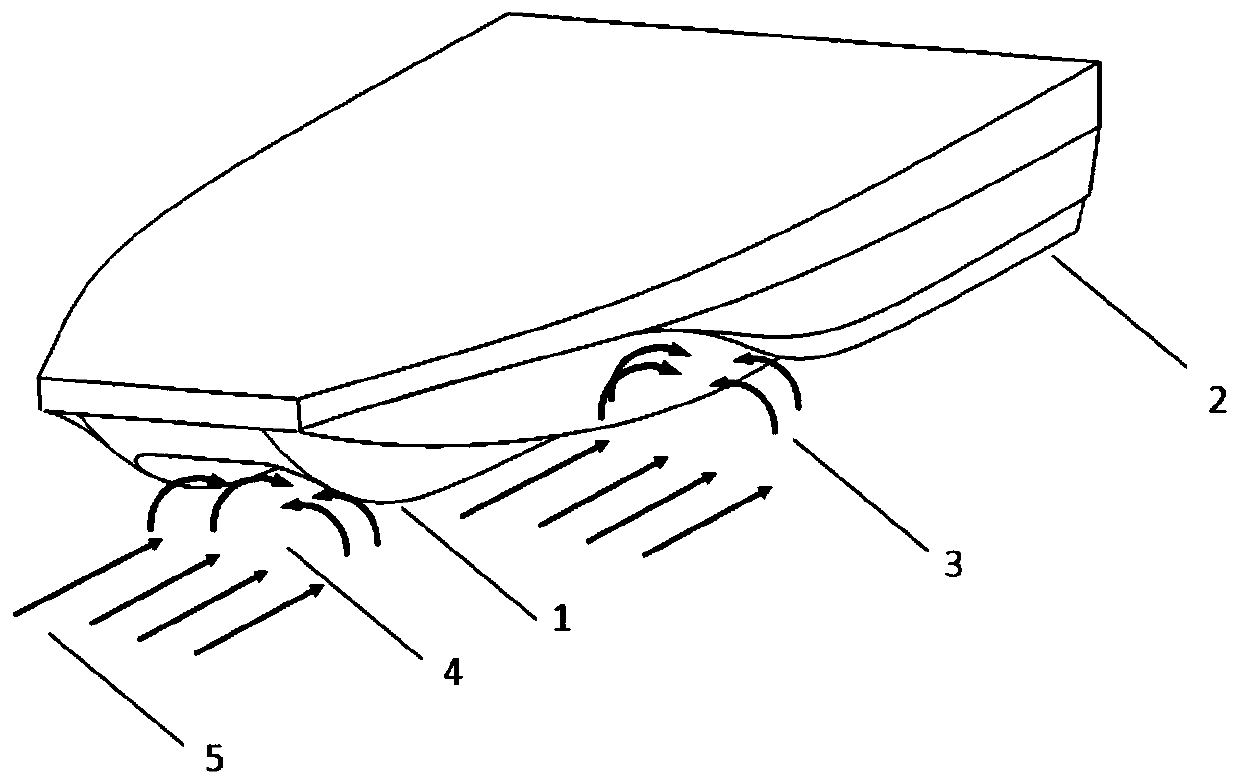

Sea condition self-adaption planing boat capable of adjusting forms

ActiveCN108557004AFastBoth seakeepingWatercraft hull designHydrodynamic/hydrostatic featuresMutual transformationStern

The invention provides a sea condition self-adaption planing boat capable of adjusting forms. The planing boat is composed of a main hull located in the middle and sheets hinged to two sides of the main hull, and the main hull and the sheets are connected through a sheet rotating deploying and retracting device. The sheets on the two sides start at 40% of the length of the boat and extend to a stern, the two sheets are independent, and the deck edges of the sheets are hinged to the main hull. The inner side shape of the sheets is completely attached to the outer side of the main hull, and folding corners are arranged on the outer side. By means of the rotating deploying and retracting device on a deck of the main hull, the sheets can be rotated and self-locked around the hinged position, so that the relative movement of the sheets and the main hull is realized. In response to the sea conditions of different wave levels, the mutual transformation between a single-hull boat form and an M-type boat form of the planing boat can be realized by rotating and deploying and retracting of the sheets, so as to improve the speedability or wave resistance of the planing boat and enhance the ability of the planing boat to complete a task.

Owner:HARBIN ENG UNIV

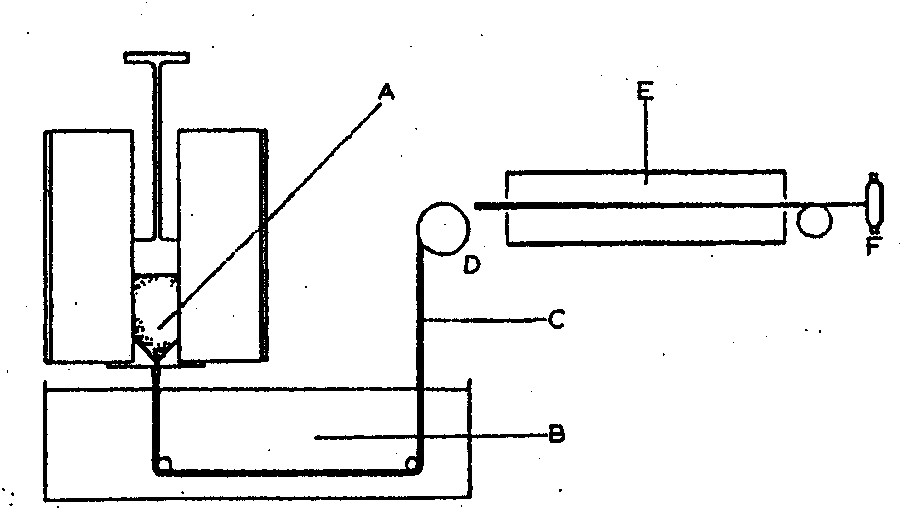

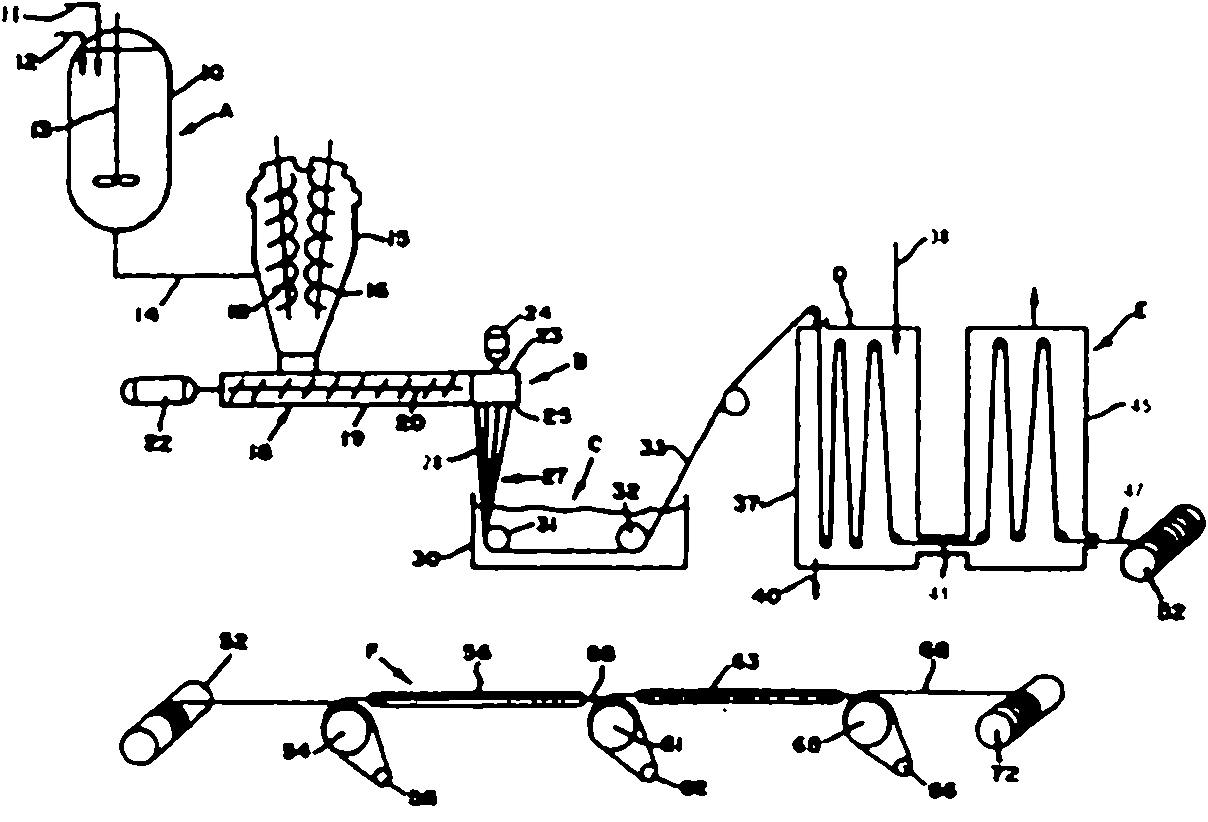

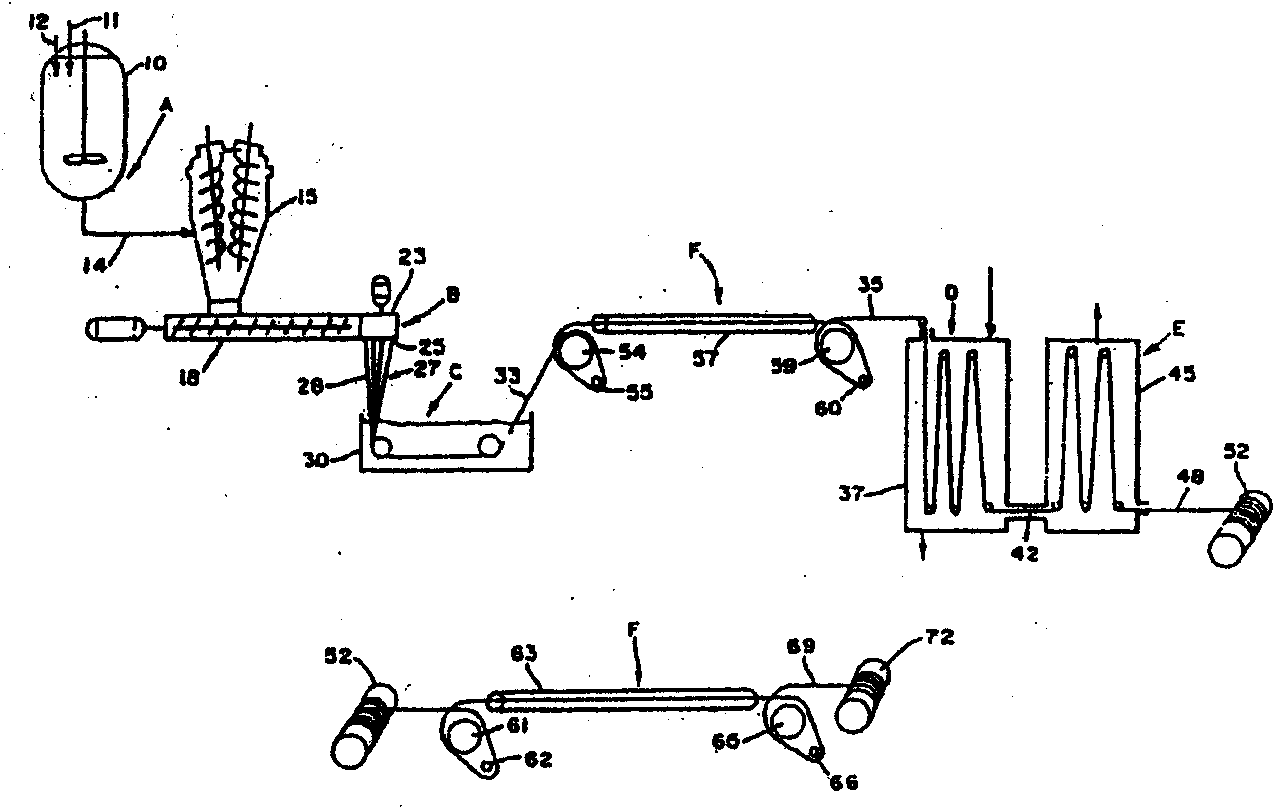

Environment-friendly and energy-saving multi-stage combination type high-performance fiber hyperploid heat drawing device

InactiveCN101775667AEmission reductionImprove stretching efficiencyArtificial thread manufacturing machinesStretch-spinning methodsFiberYarn

The invention relates to an environment-friendly and energy-saving multi-stage combination type high-performance fiber hyperploid heat drawing device, which is characterized in that pre-drawing drying ovens and a plurality of drawing heat drying ovens are independently arranged in a closed heat preservation box; the upper parts of all the pre-drawing drying ovens and the drawing heat drying ovens which are arranged independently are all provided wit air exhaust devices; a pre-drawing machine is arranged in each pre-drawing drying oven; and a drawing machine is arranged in each drawing heat drying oven. The invention has the advantages of environmental protection, energy saving and high drawing efficiency and can reduce pernicious and hazardous gas emission by 95%, save the energy by 50%-75%, and improve the yield by 150%-300%; in addition, the fiber property intensity of the same primary raw silk can be improved greatly by the drawing means. The invention also has the advantages of low drawing multiple per stage, rare yarn break, less waste, low equipment manufacture cost, reliable performance as well as convenient maintenance and use.

Owner:上海博迪纺织新材料有限公司 +1

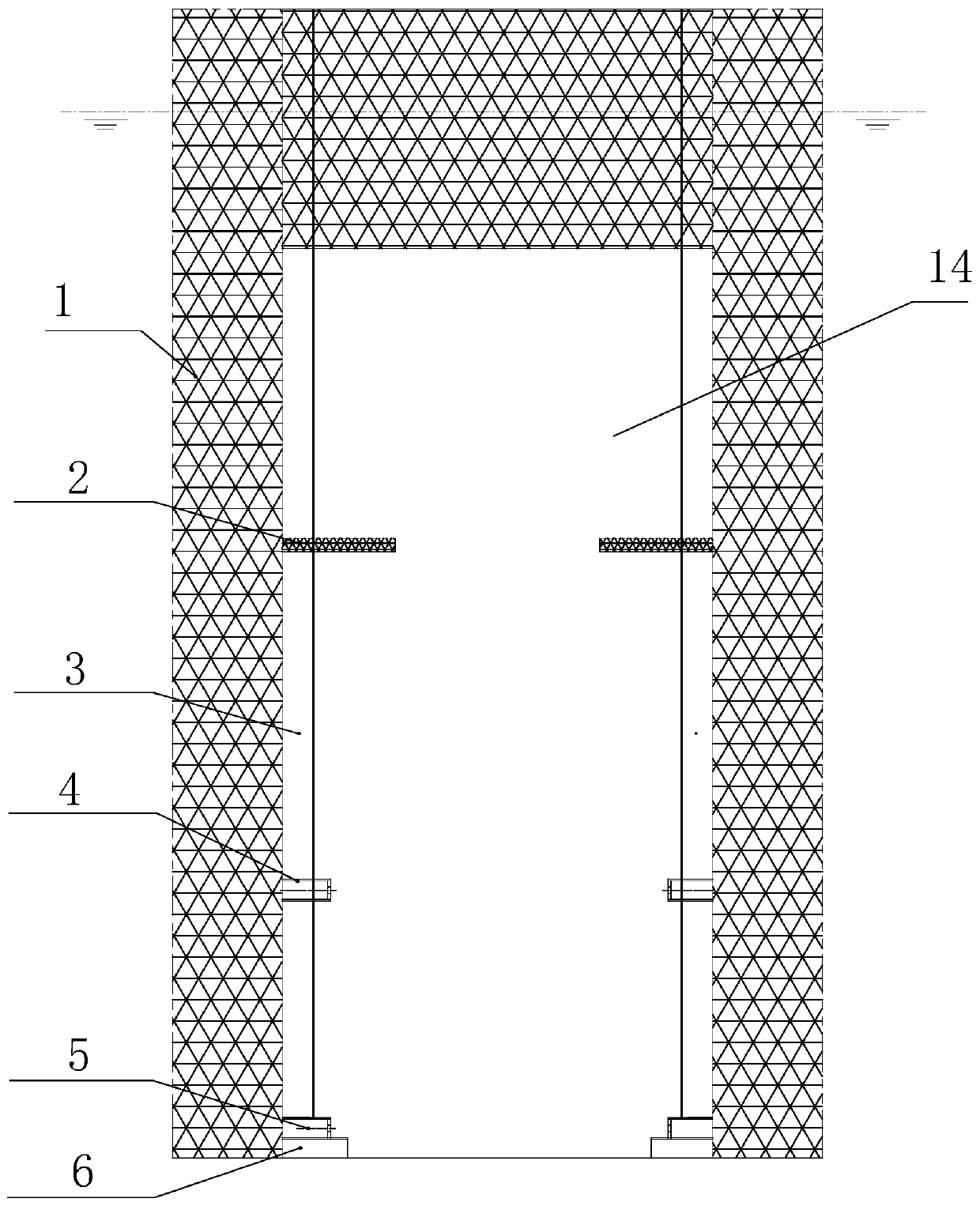

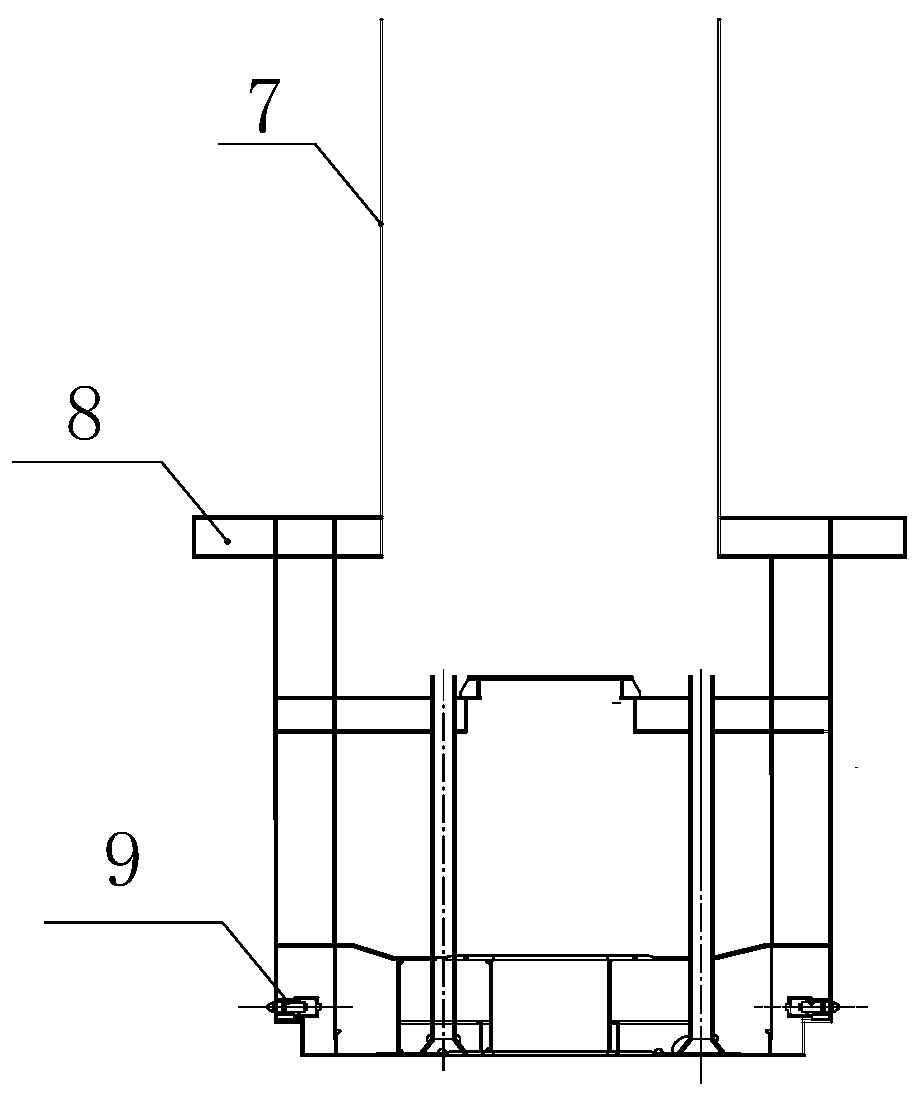

Telescopic propeller system capable of being maintained in ship

InactiveCN110758702ALow costEnsure safetyPropulsion power plantsPropulsive elementsHull structureStructural engineering

The invention discloses a telescopic propeller system capable of being maintained in a ship. The telescopic propeller system comprises a propeller mounting area which is provided with a lower supporting structure and a hull structure platform, and a structural box body which is used for fixing a propeller and arranged in the propeller mounting area through a hydraulic lifting cylinder. When the structural box body descends to touch the lower supporting structure and stops moving, the underwater part of the propeller is just completely exposed out of the ship, and a pin opening position in a lower locking structure right corresponds to a pin position of the structural box body. When the structural box body rises to touch the hull structure platform and stops moving and the underwater part of the propeller is retracted into the ship, a pin opening position in an upper locking structure corresponds to the pin position of the structural box body. When the propeller breaks down, personnel only need to retract the propeller and enter the hull structure platform to maintain the propeller, and the cost for propeller fault maintenance is greatly reduced.

Owner:DALIAN SHIPBUILDING IND

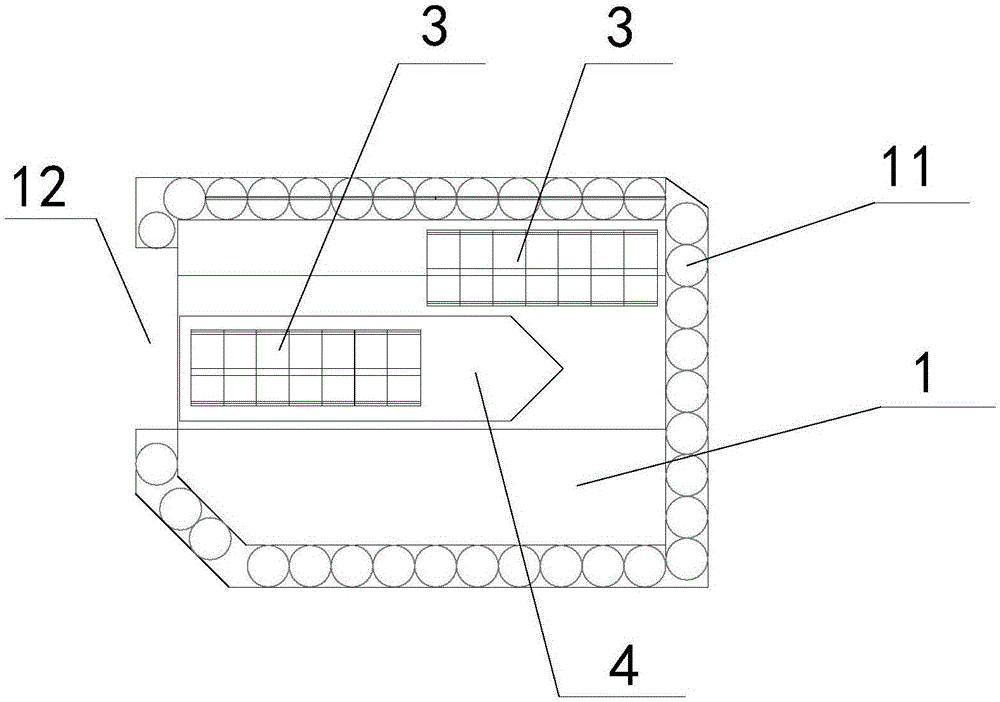

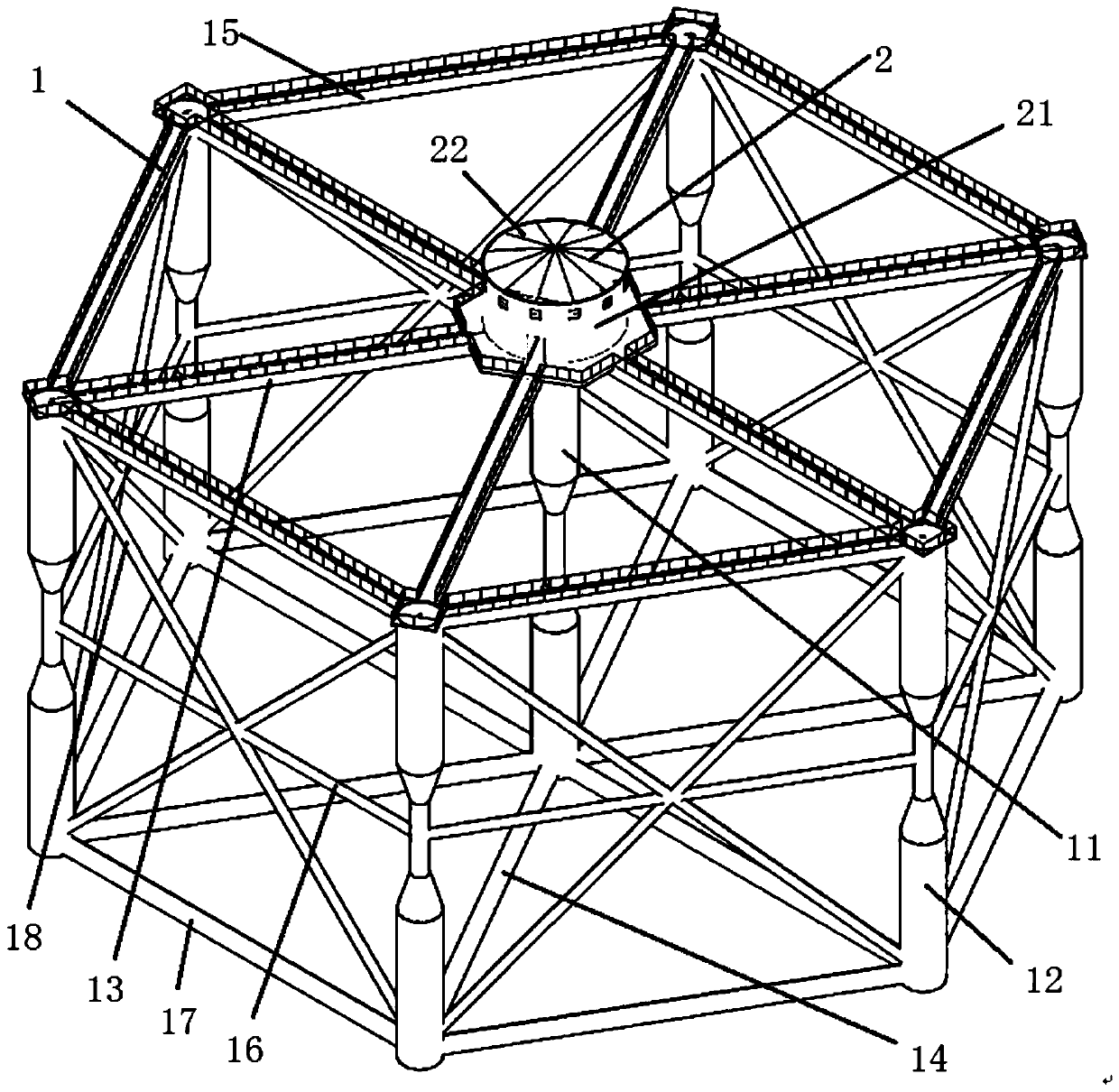

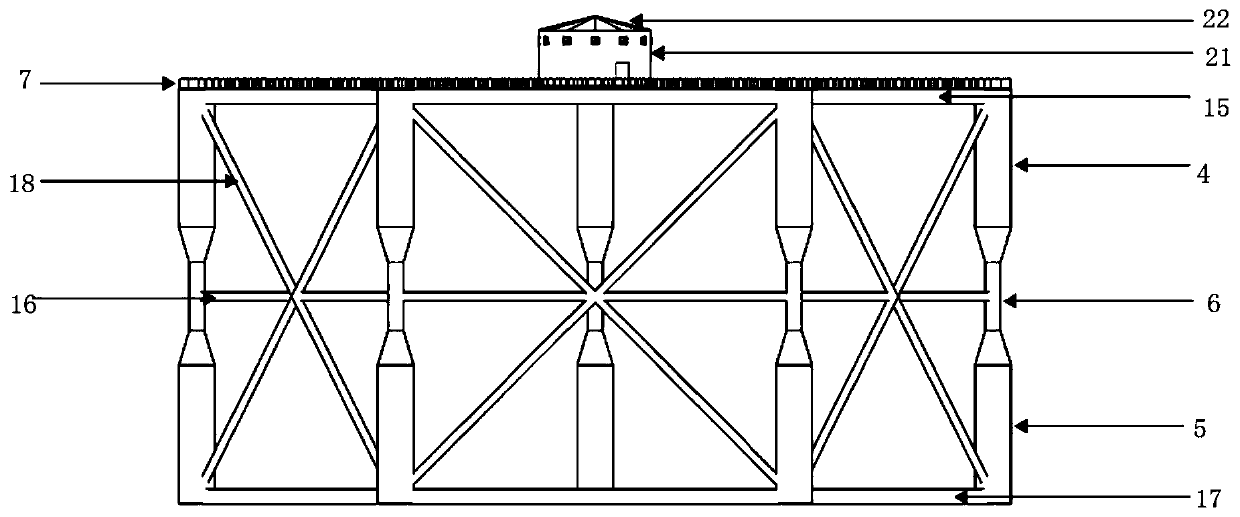

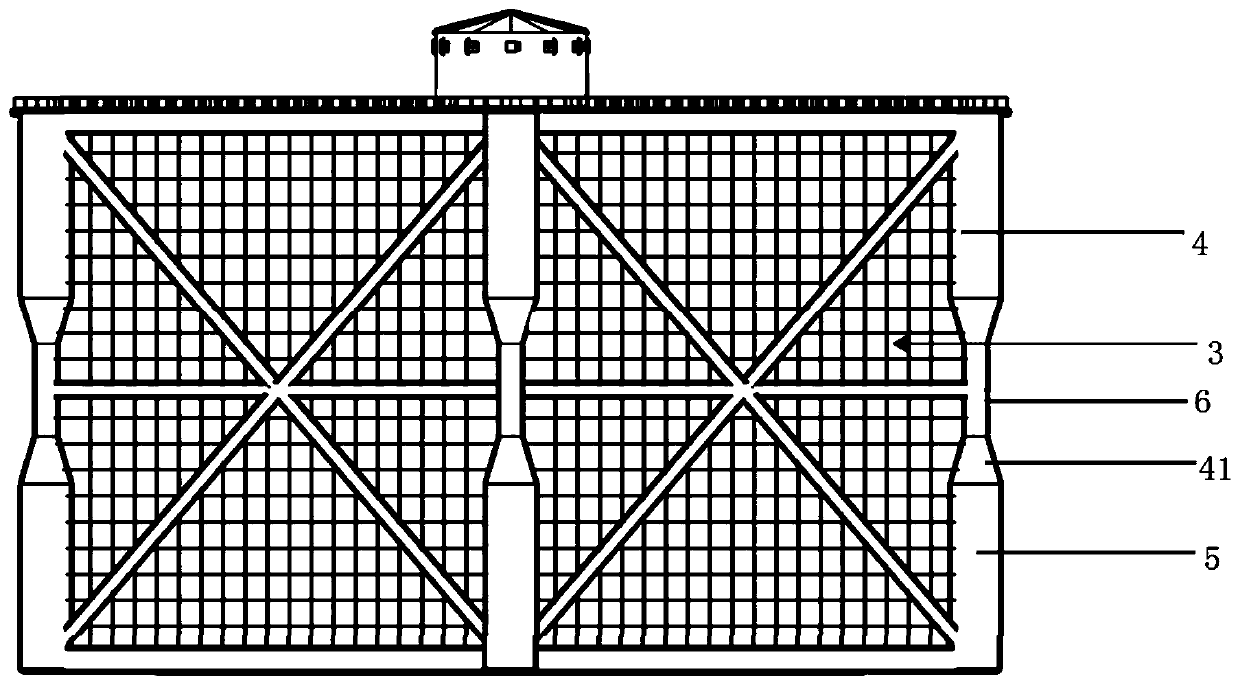

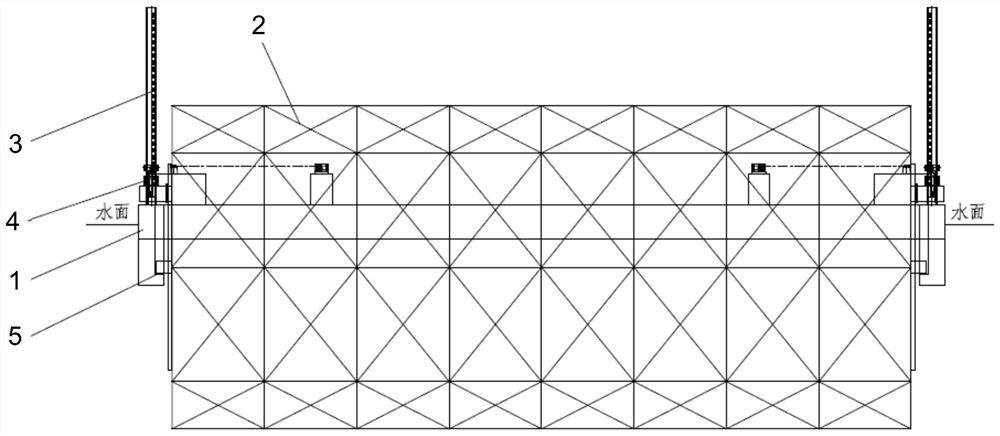

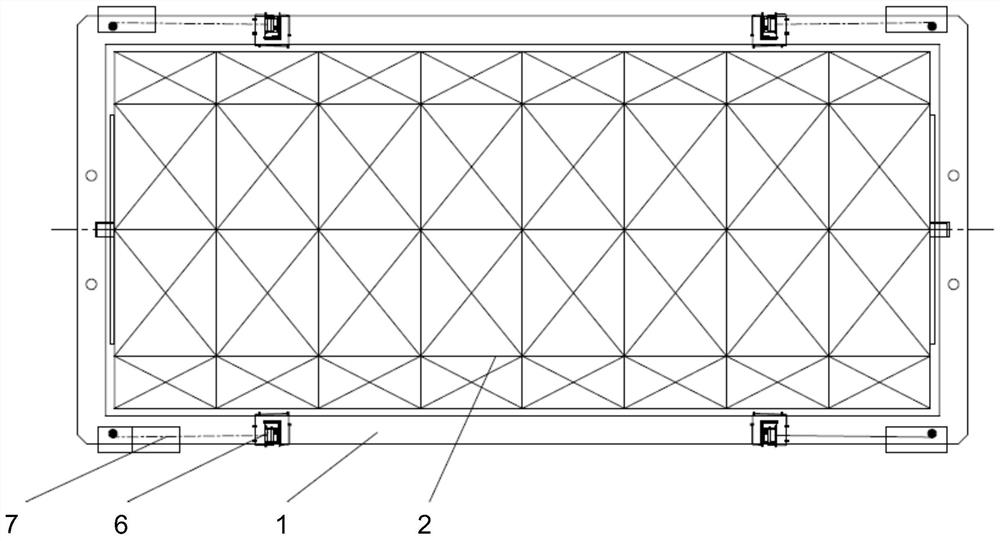

Semi-submersible offshore fishing ground platform with lightweight frame structure

PendingCN111348154AGuaranteed normal operationAchieve normal workClimate change adaptationVessel safetyMarine engineeringControl room

The invention provides a semi-submersible offshore fishing ground platform of a lightweight frame structure. The semi-submersible offshore fishing ground platform comprises a main body frame, a control room arranged at the top of the main body frame and netting installed on the side wall and the bottom of the main body frame. The main body frame comprises a central stand column, a plurality of external stand columns which are uniformly arranged around the central stand column, an upper horizontal support, a lower horizontal support, an upper chord pipe, a middle chord pipe, a lower chord pipeand an inclined support; the center stand column and the exteranl stand columns are the same in structure and each comprise an upper float bowl arranged on the upper portion, a middle stand column fixedly connected with the bottom of the upper float bowl and a lower float bowl fixedly connected with the bottom of the middle stand column. The fishery platform is light and stable in structure, the inclination angle can be controlled within 20 degrees in a normal operation state, the motion amplitude does not exceed 1 / 5 of the diameter of the breeding platform, and safety and stability of the breeding platform can be guaranteed.

Owner:DALIAN UNIV OF TECH

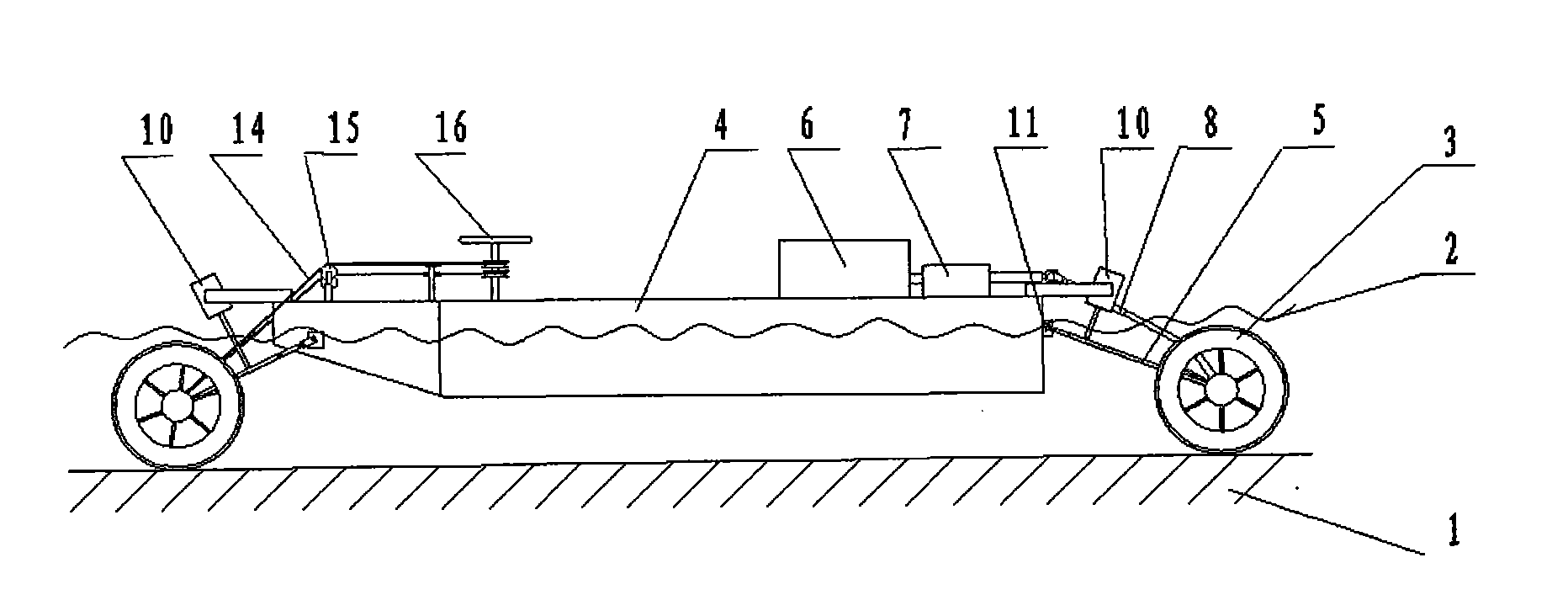

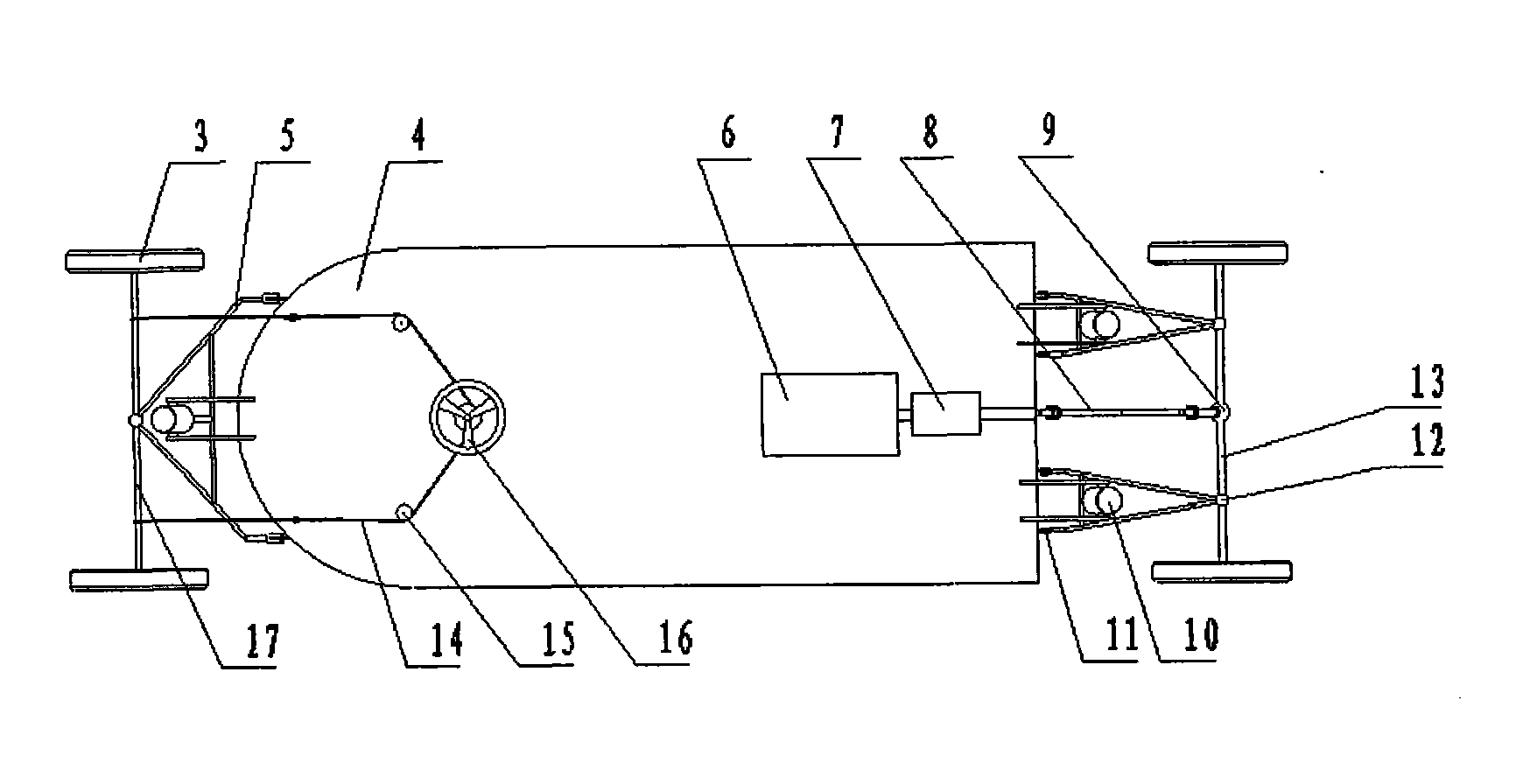

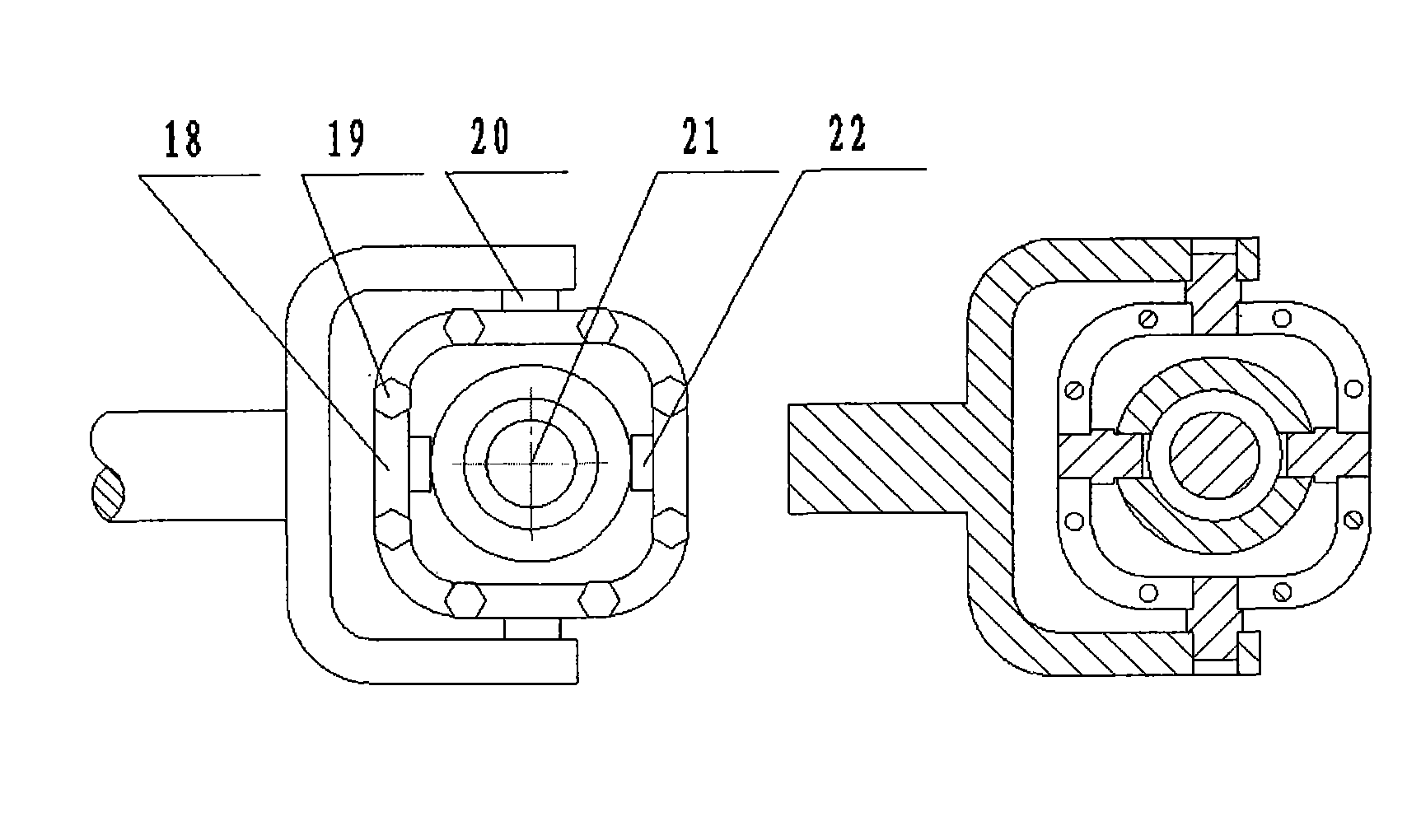

Shallow water bottom wheel propelled ship and propelling method thereof

InactiveCN101857081ASimple structureLow costPropulsive elementsRotational freedomDifferential transmission

The invention relates to a ship sailing in shallow water, in particular to a shallow water bottom wheel propelled ship and a propelling method thereof, providing a ship which has simple structure, low cost and capability of sailing in shallow water and a method. The invention is realized by utilizing power to drive bottom wheel to roll on submerged soil so as to propel a ship body to sail. The structure thereof comprises the ship body and a drive mechanism, wherein the bow and stern of the ship body are provided with a bottom wheel; an arranged differential transmission case ensures that left and right wheel axles (21) have different speeds when the bottom wheel rotates, thus realizing differential motions; a spherical hinge linkage with two rotational freedom degrees is arranged at the ship body, and is structurally provided with two pins (22) which have the difference of 180 degrees; a prong is provided with two prong pins (20); and driving bottom wheel shafts are sheathed with annular quadripuntal connecting plates (18) which are connected together through bolts (19), thus the bottom wheels can adapt to the changes of water and uneven water bottom, can roll on the submerged soil to generate propulsion and transmit the propulsion to the ship body, thus enabling the ship body to make sailing movements of forwarding and making a turn.

Owner:山东省黄河三角洲可持续发展研究院

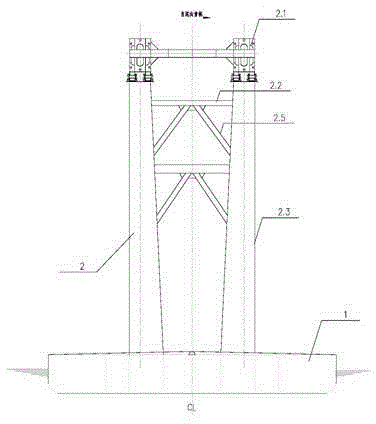

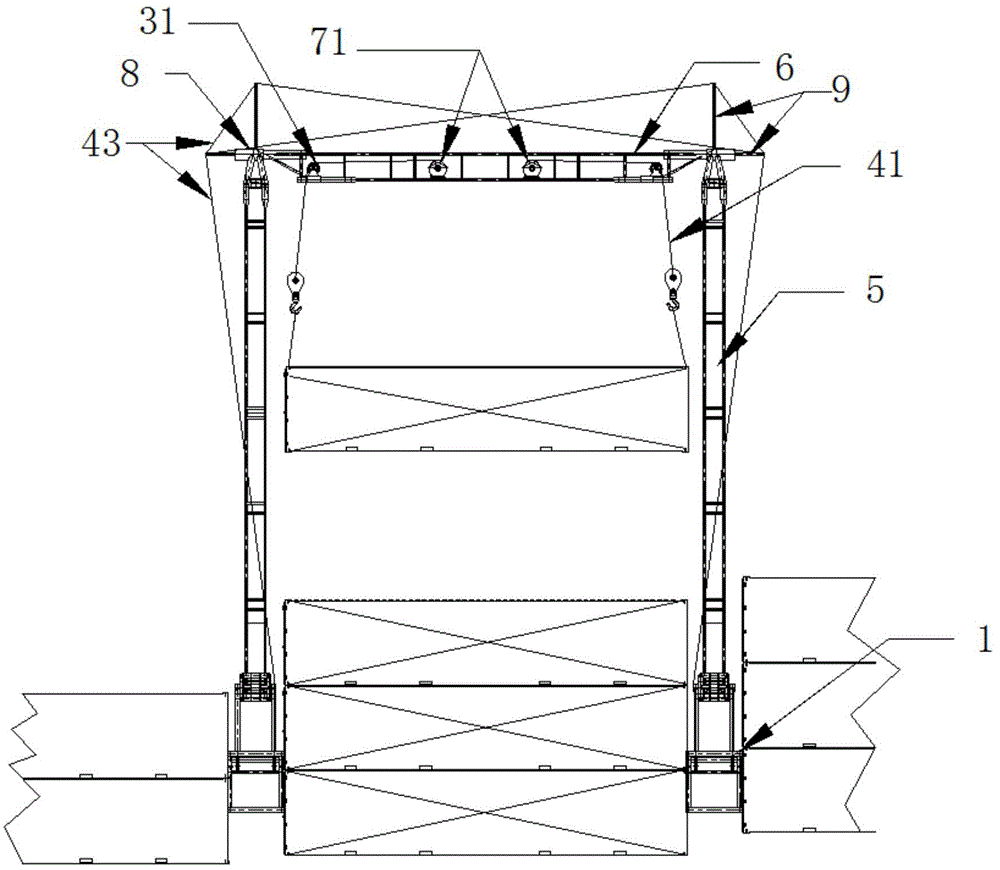

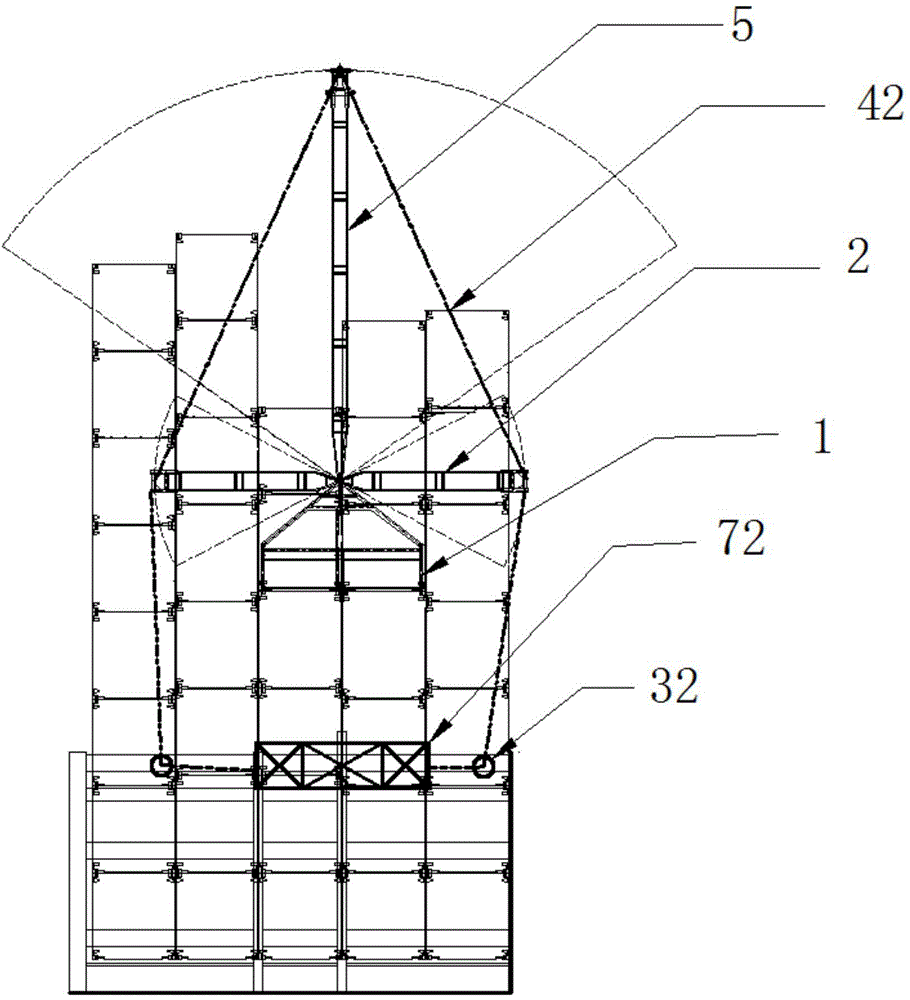

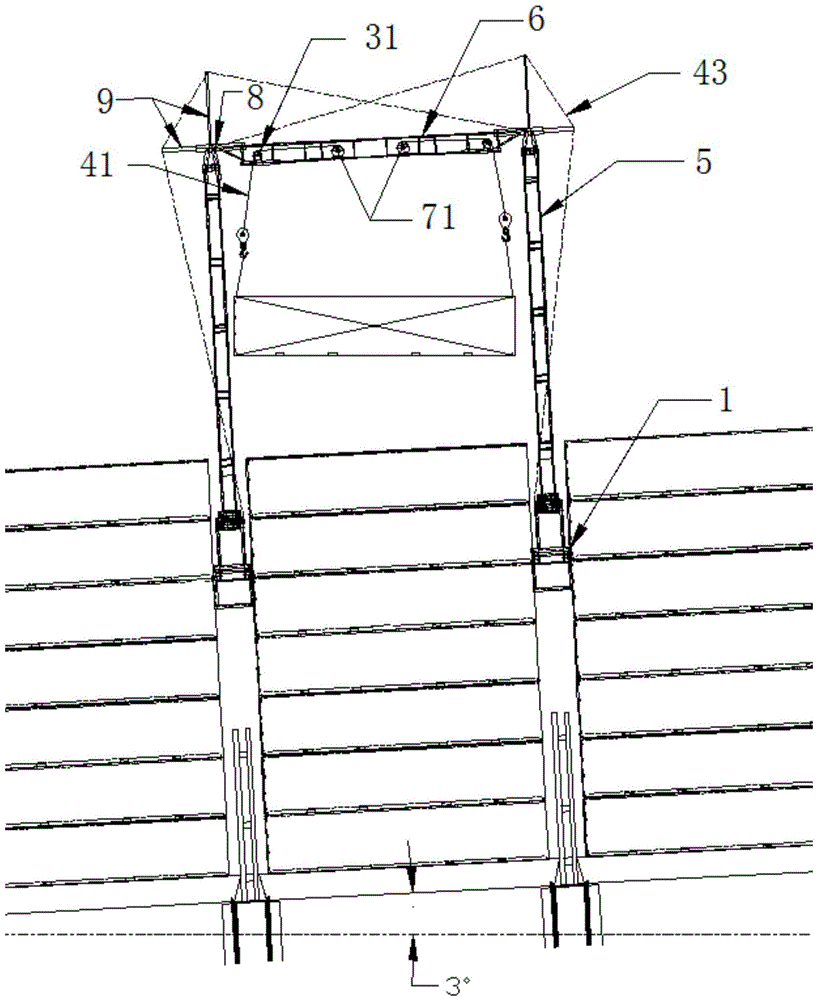

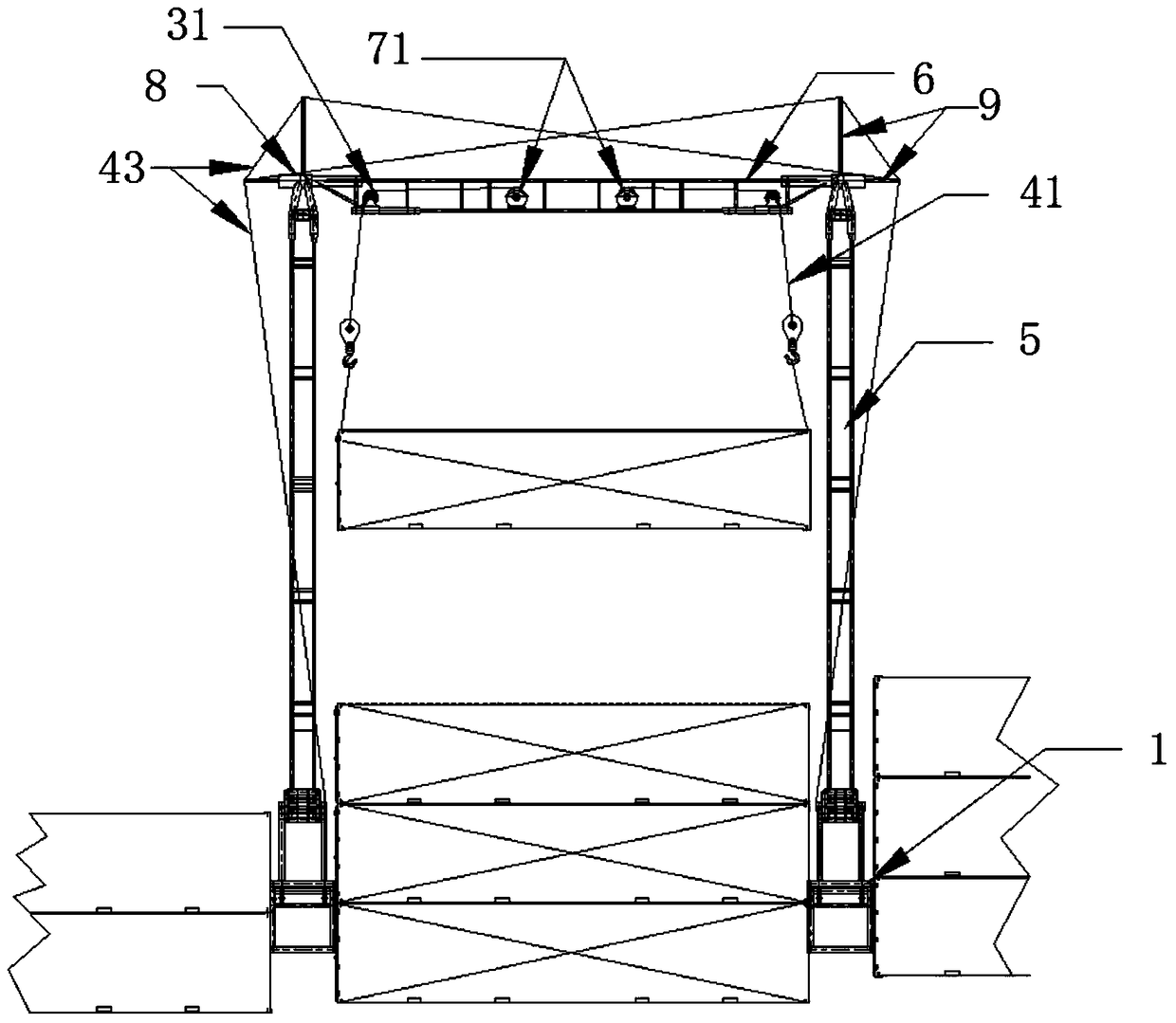

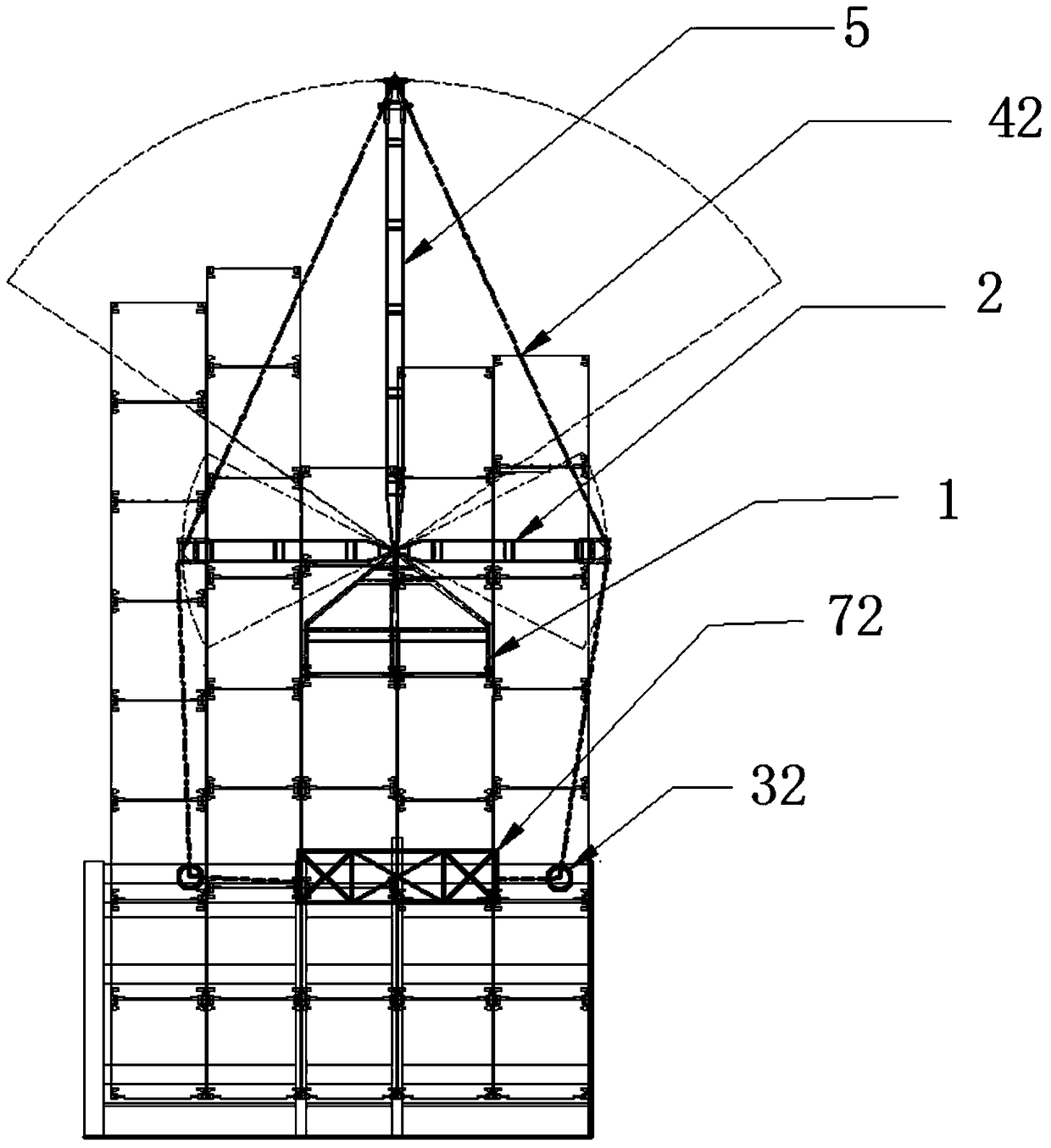

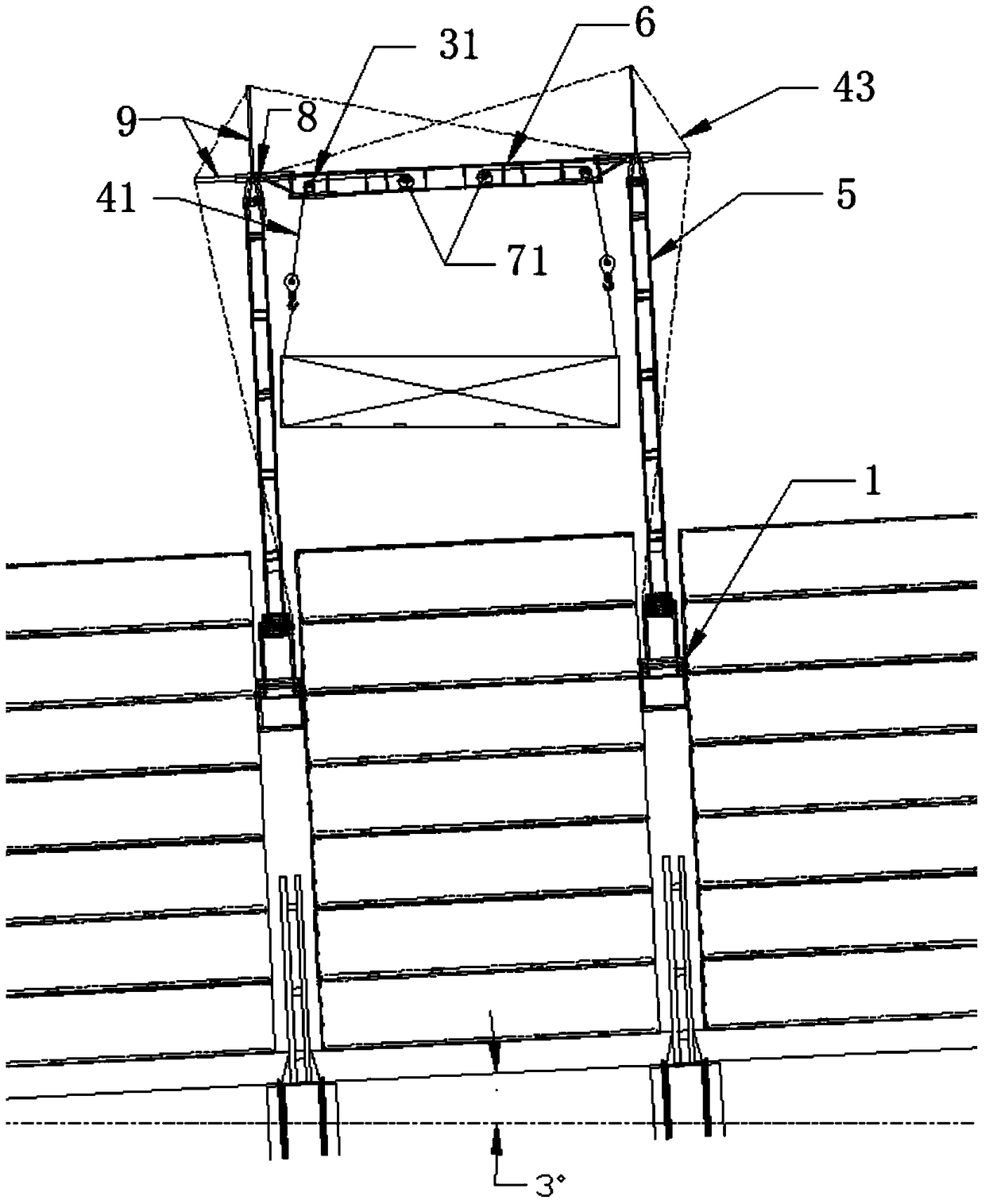

Special lifting and vibration-driving ship for integrated driving of cell type steel sheet pile large cylinders and vice cells

InactiveCN104627326ASmall draftThe scope of application of water operations has increasedWaterborne vesselsCranesMarine engineeringSheet pile

The invention discloses a special lifting and vibration-driving ship for integrated driving of cell type steel sheet pile large cylinders and vice cells. The special lifting and vibration-driving ship comprises a special integrated driving crane ship mother ship provided with a special lifting device and special vibration-driving equipment. The special lifting device is fixed to the crane ship mother ship, is of a T-shaped two-arm structure and is composed of two lifting devices in left-right symmetry. The special vibration-driving equipment and the special lifting device cooperate to be used for integrated lifting and integrated vibration-driving of the cell-type steel sheet pile vice cells. By the adoption of the special lifting and vibration-driving ship, all working procedures, in the whole process of steel sheet pile vibration-driving, comprising steel sheet pile lifting, descending and vibration-driving can be completed at a time, there is no need to perform unclasping or replace pile hammers or perform seam vibration-driving after steel sheet pile lifting and descending, and therefore working efficiency is greatly improved.

Owner:CCCC THIRD HARBOR ENG +2

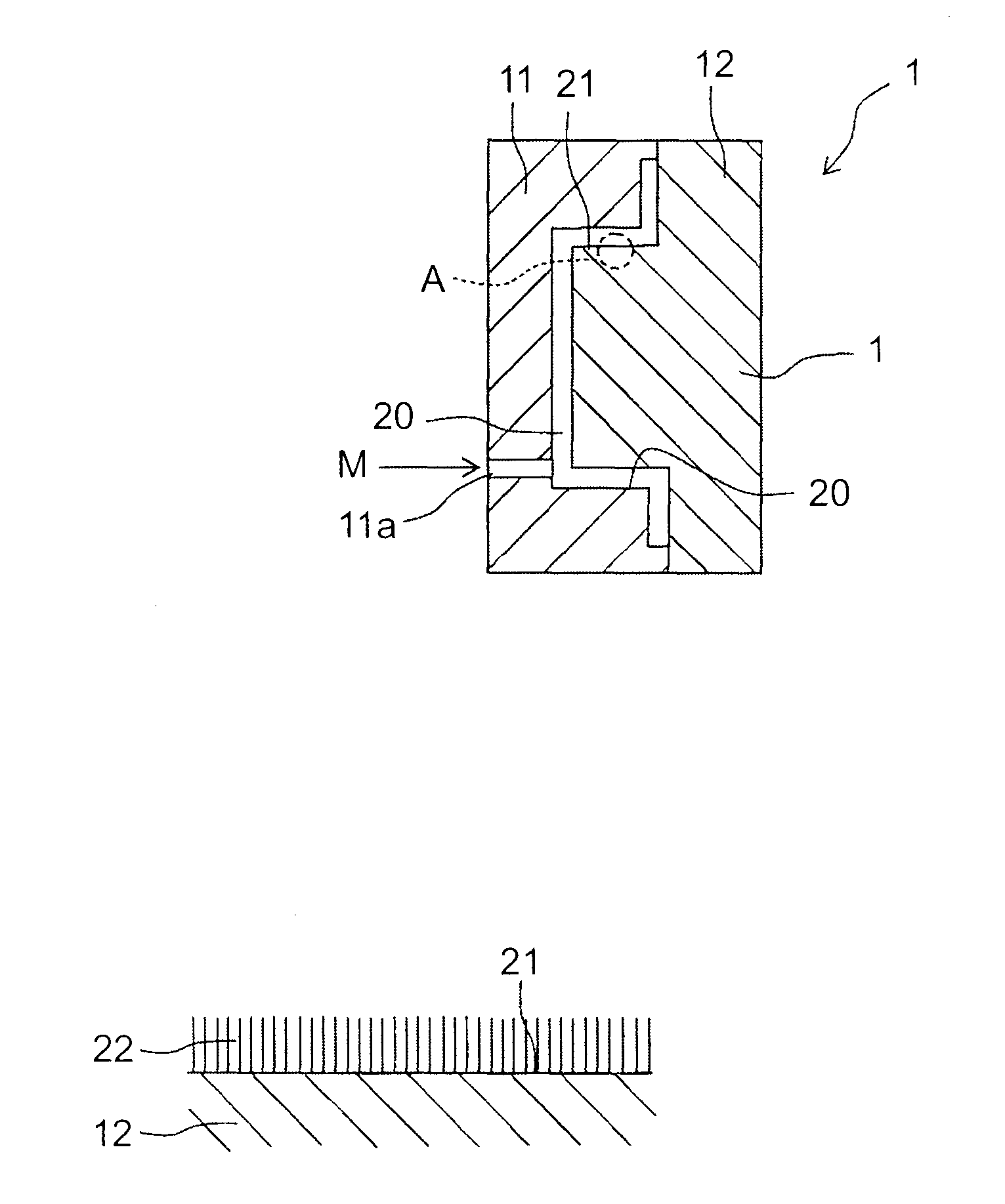

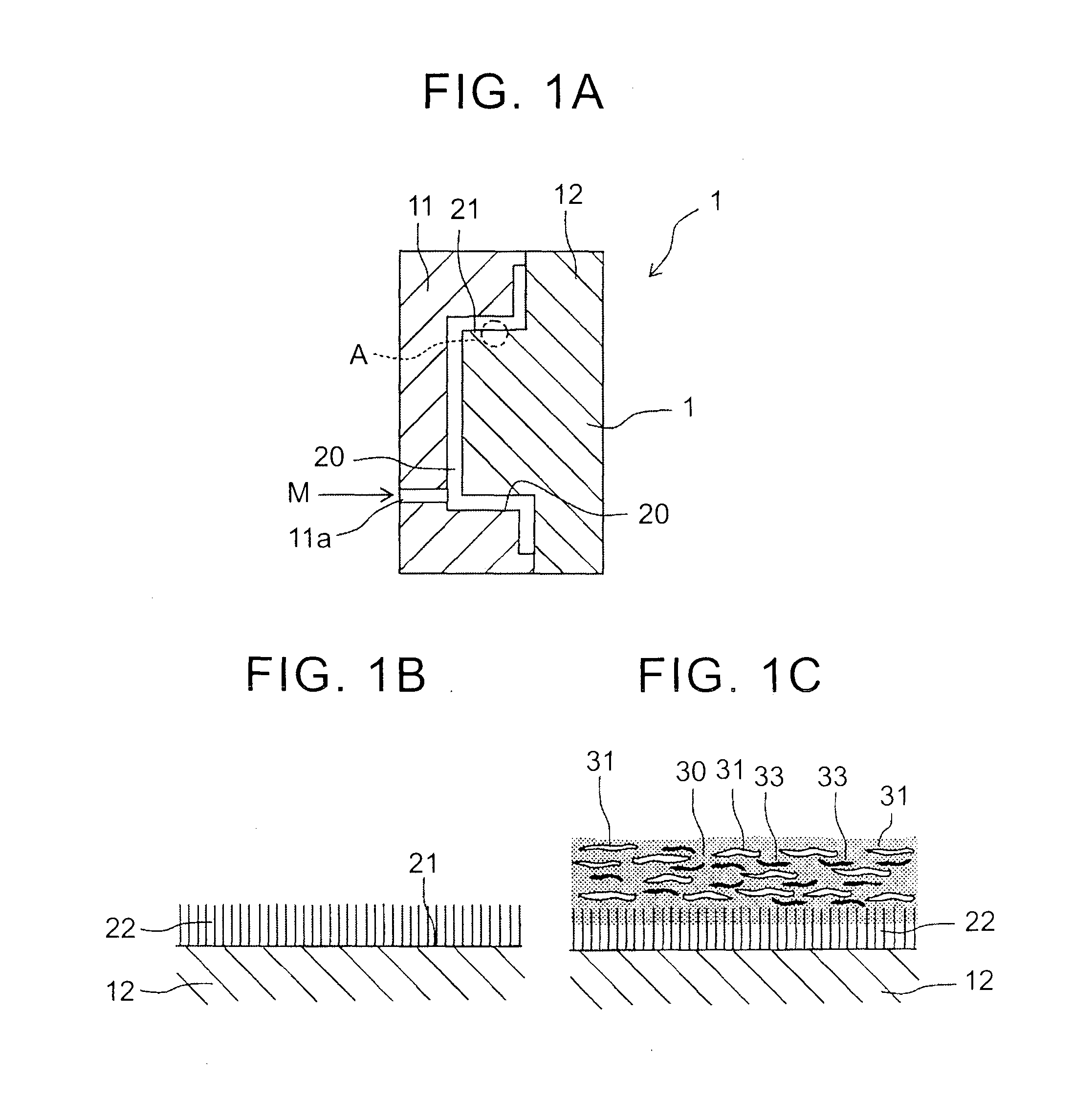

Casting mold and cast article produced using the same

A casting mold includes a carbon film with which at least a surface of the casting mold which forms a cavity is covered, and mold oil with which a surface of the carbon film is coated. In the casting mold, aluminum powder is added to the mold oil.

Owner:TOYOTA JIDOSHA KK

Planing boat with three-channel structure

InactiveCN110682995AStrong penetrating powerReduce sailing resistanceWatercraft hull designHydrodynamic/hydrostatic featuresWater flowMechanical engineering

The invention belongs to the technical field of planing boats, and particularly relates to a planing boat with a three-channel structure. The planing boat is the further improvement on a channel planing boat. Due to adoption of the design of three channels, bow made waves and wave loads can be absorbed during high-speed sailing, meanwhile, slamming loads of waves at the bow of the planing boat arereduced, planing postures are improved, and the sailing stability of the planing boat is improved. During high-speed sailing of the planing boat, an air film and a splashing water flow layer can be formed in each channel, and loads caused when waves directly slam the bow are reduced. Front air incoming flow can be guided to the boat bottom through the channels, accordingly, a boat body is elevated, drinking water of the boat is reduced, and the sailing resistance of the planing boat is reduced. The width of the channel at the middle portion is larger than the width of the channels on the twosides, the height of the channel is larger so that front incoming air can be widely absorbed to the bottom of the boat body, and meanwhile due to the large channel width, the made waves generated by amain boat body can be further absorbed.

Owner:HARBIN ENG UNIV

Assembled crane for container vessel and assembling manner of assembled crane

InactiveCN106143808AReduce weightBalance weightCargo handling apparatusPassenger handling apparatusEngineeringWinch

The problem to be solved by the present invention is to provide a container ship assembled crane and its assembly method. The assembly tools and components are placed in a special container, and are installed between the containers on the upper deck of the container ship during operation, including the channel beam structure on the container ship. , a crane top beam, a number of crane foundations, a number of crane outriggers, a number of steel arm structures, a number of lifting pulley blocks, a number of luffing pulley blocks, a number of lifting winches and a number of luffing winches; the crane foundation includes a crane base 1. Corner fittings; the corner fittings are provided with corner fitting holes, and the base of the crane is provided with bayonet pins. In the working state, the bayonet pins on the crane base are inserted into the corner fitting holes for fixed connection. The beneficial effects are: the assembly can be quickly completed, the container can be unloaded urgently, the purpose of reducing and balancing the weight of the container ship, reducing the draft, and straightening the ship can be achieved, and the occurrence of accidents such as running aground, breaking the cabin, and running aground on large and super large container ships can be minimized. , resulting in casualties and property damage.

Owner:HUAXIA OCEAN ENERGY ENG TIANJIN

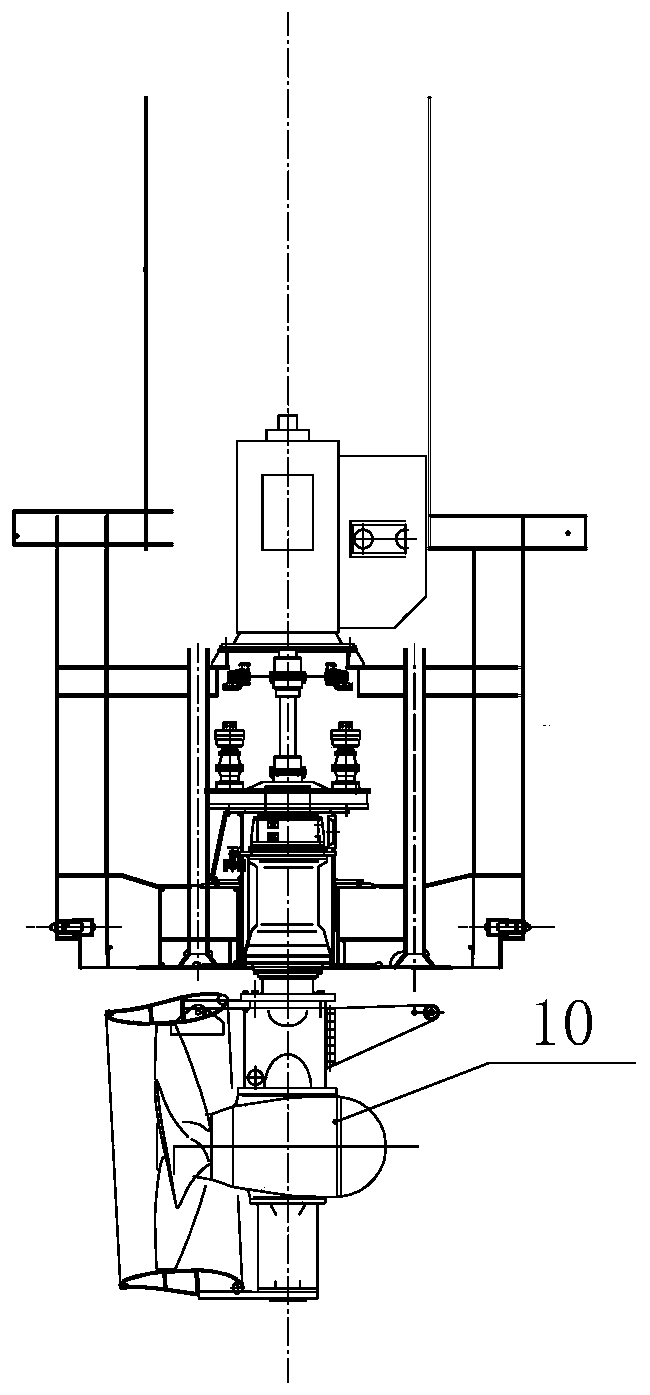

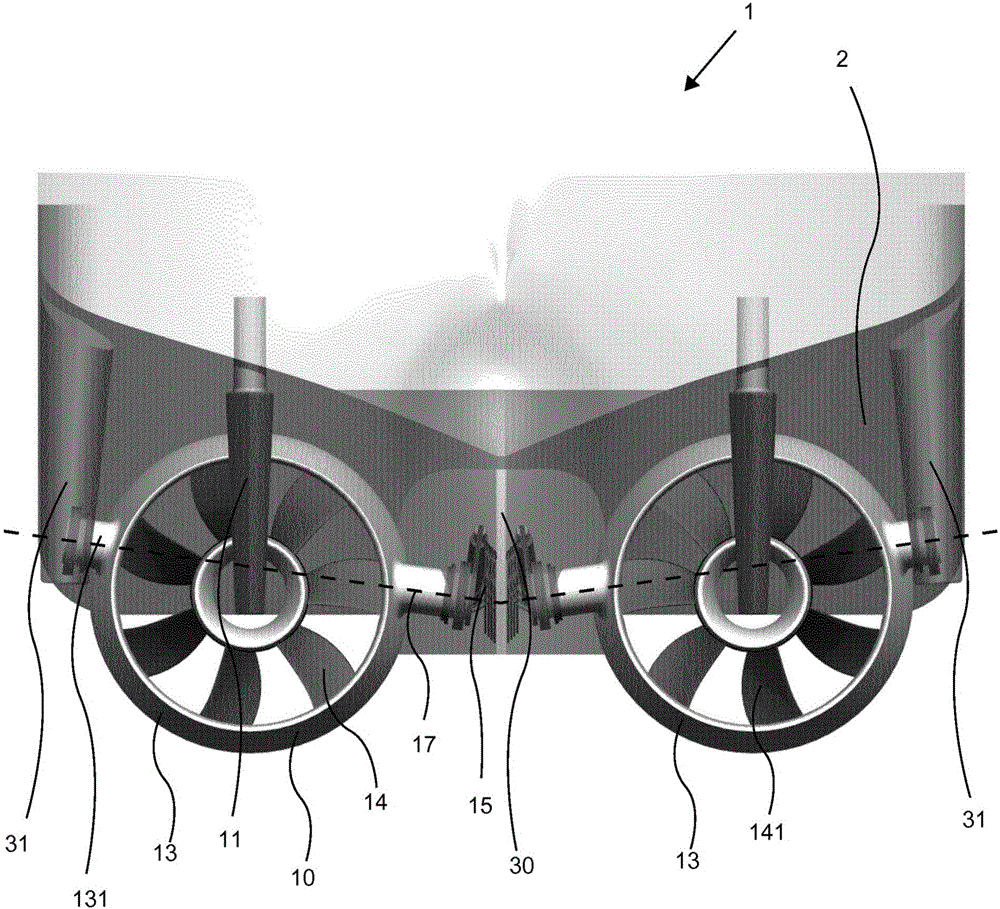

A vessel comprising a propulsion unit

A vessel comprising a propulsion unit (10), the propulsion unit having a propeller (14), where the propulsion unit is arranged to be pivoted to any orientation between a first deployed orientation and a second retracted orientation, where in the first orientation the propeller provides thrust in a thrust direction for moving the vessel and in the second orientation is pivoted around a pivoting axis (17), wherein the pivoting axis is proximate to a propeller bearing located near or at the propeller, in a way such that in the second orientation, the propulsion unit is substantially flush with a hull (2) of the vessel, and wherein energy for providing thrust to the propulsion unit is supplied in manner adapted to allow pivoting of the propulsion unit between the first and the second orientation. The document further relates to a use of such a vessel, which is in particular suited for combined operation in deep as well as shallow water.

Owner:ROLLS ROYCE MARINE

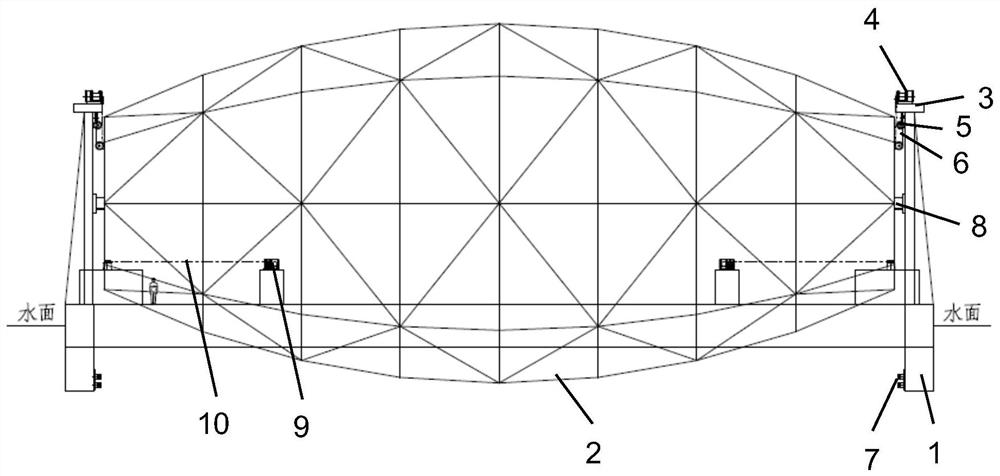

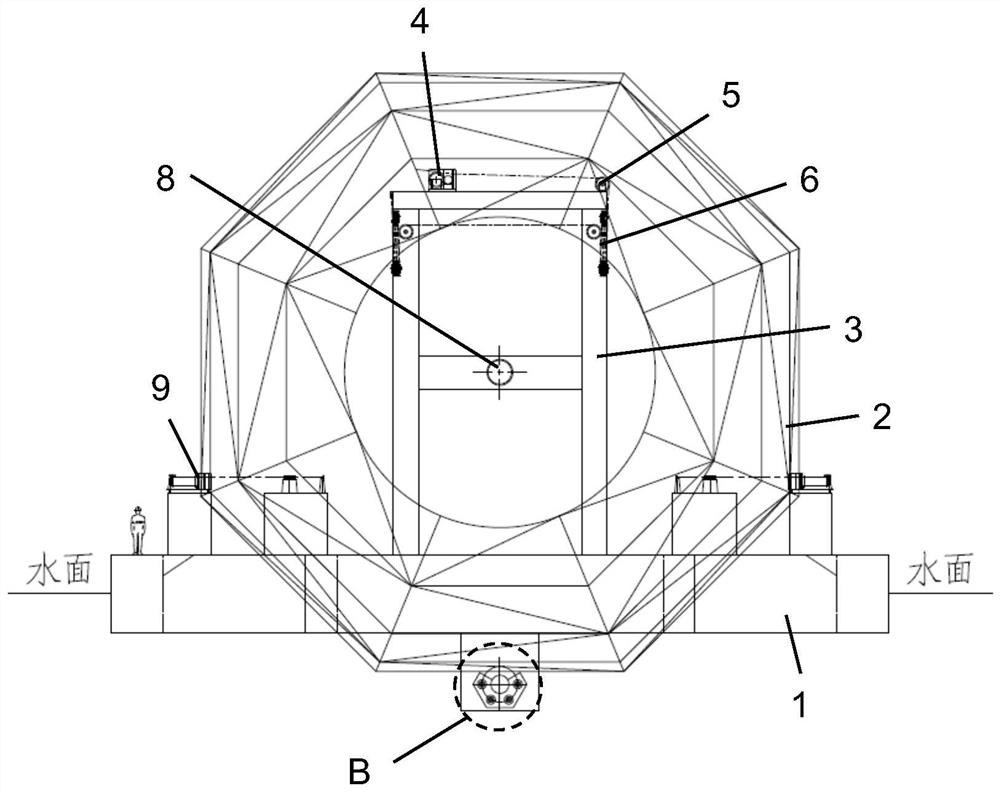

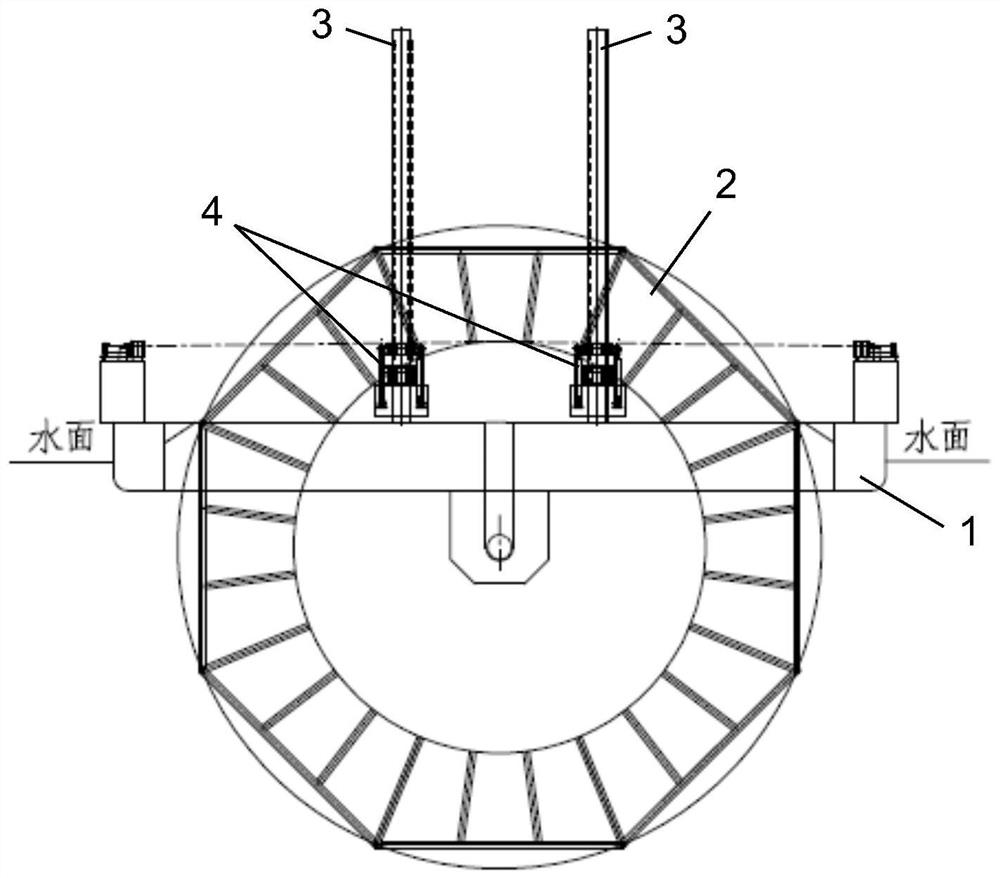

Raising rotatable sea fish breeding net cage and use method thereof

PendingCN111616090ASmall draftEasy towingClimate change adaptationLifting framesMarine fishEngineering

The invention discloses a raising rotatable sea fish breeding net cage and a use method thereof. The raising rotatable sea fish breeding net cage comprises structure floating bodies, a breeding net cage body, a lifting mechanism and a rotating mechanism, wherein the structure floating bodies float on a water surface, and a hanger is arranged on each structure floating body; the lifting mechanism is arranged on the hangers, and is connected with the breeding net cage body; the breeding net cage body realizes rising / falling movement relative to the structure floating bodies through the lifting mechanism; a fishing net is used for coating the surface of the breeding net cage body; and the rotating mechanism is arranged on the structure floating bodies and is connected with the breeding net cage body so that when the breeding net cage body is in a falling state, rotary net drying of the breeding net cage body is realized. According to the raising rotatable sea fish breeding net cage disclosed by the invention, a net cage can have the functions of lifting and rotating, so that draft of the net cage is reduced, the difficult problems of hauling and docking for repair and maintenance of the net cage, and adult fish capturing can be solved, the difficult problem of frequent replacement of fishing nets caused by marine organism adhering is solved, and breakage of the fishing nets is convenient to examine.

Owner:SHANGHAI ZHENHUA HEAVY IND

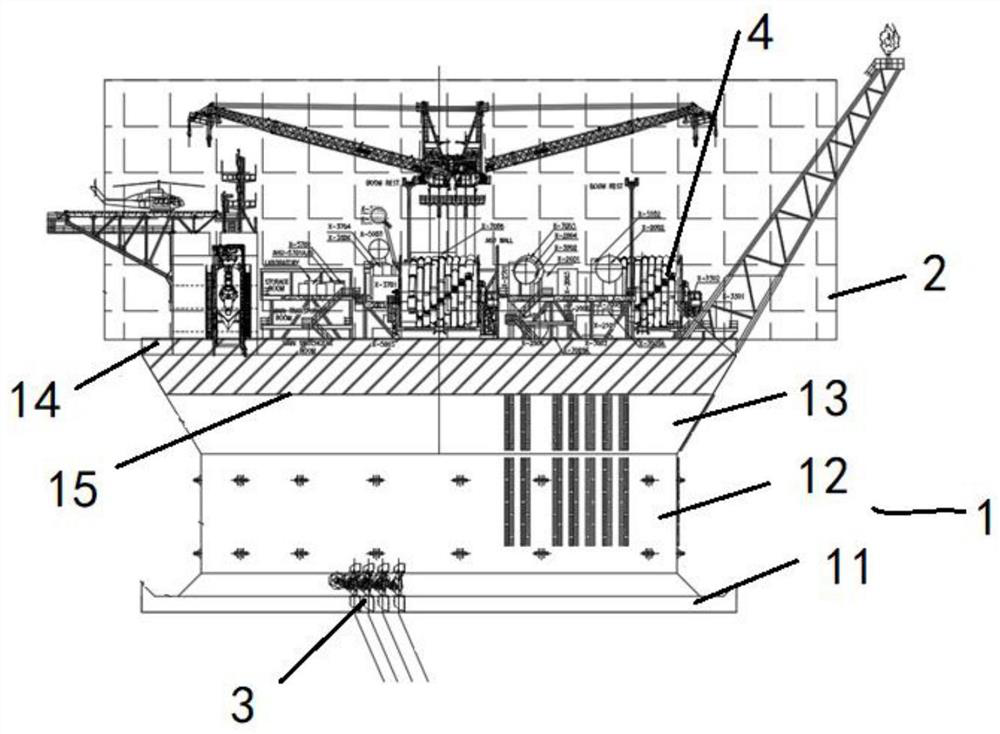

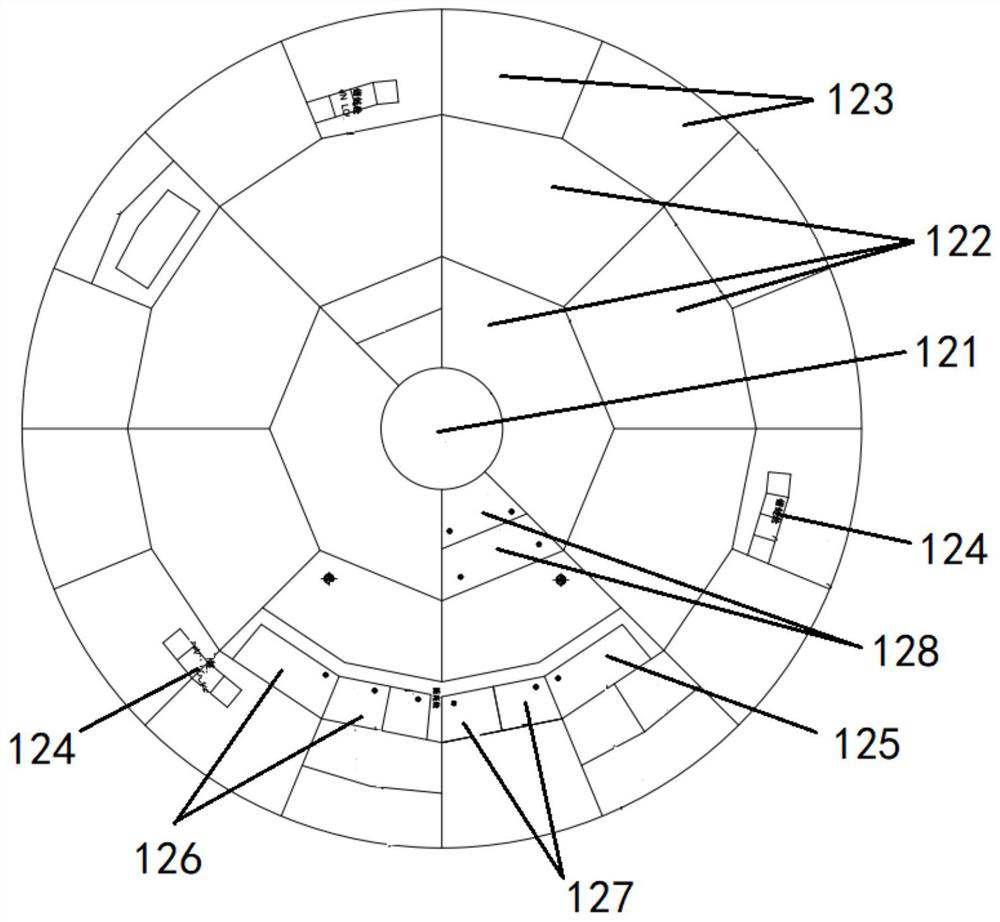

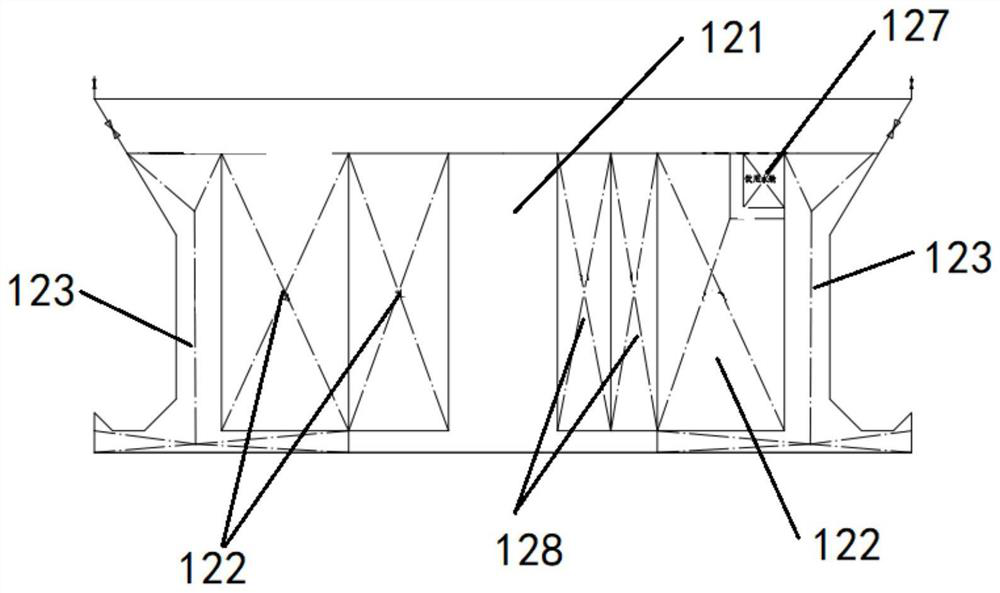

Cylindrical FPSO suitable for multi-point mooring system

ActiveCN113371146ASolve the current situation of dependence on importsSave engineering investmentFloating buildingsAnchoring arrangementsMooring systemClassical mechanics

The invention relates to a cylindrical FPSO suitable for a multi-point mooring system, which comprises a ship body and an upper module mounted on the ship body, the ship body comprises a damping plate; a cylindrical barrel which is installed on the damping plate, the interior of the cylindrical barrel is divided into a void cabin, a crude oil cabin and a ballast water cabin, and a load discharging system and a channel are arranged in the void cabin; and an outer floating structure which is located at the top of the cylindrical barrel, and the upper module is installed on a main deck of the outer floating structure. The cylindrical FPSO suitable for the multi-point mooring system is suitable for multi-point mooring, and the cost is reduced. In addition, the separated cabins in the cylindrical barrel are annularly arranged, the space utilization rate is high, and the cabin capacity of the crude oil cabin is large.

Owner:CHINA NAT OFFSHORE OIL CORP +1

Hydraulic lifting and rotatable marine fish culture net cage and use method thereof

PendingCN112741032ASmall draftEasy towingClimate change adaptationLifting devicesMarine fishMarine engineering

The invention discloses a hydraulically lifting and rotatable marine fish culture net cage and a use method thereof. The hydraulically lifting and rotatable marine fish culture net cage comprises a floating body, a culture net cage body, a hydraulic lifting assembly and a rotating assembly, the floating body floats on the water surface, the hydraulic lifting assembly is arranged on the floating body and connected with the culture net cage body, the culture net cage body realize ascending / descending motions relative to the floating body through the hydraulic lifting assembly, the surface of the culture net cage body is provided with a fishing net in a coated mode, and the rotating assembly is arranged on the floating body and is connected with the culture net cage body, so that the culture net cage body is in a descending state to realize rotary net sunning of the culture net cage body. According to the hydraulic lifting and rotatable marine fish culture net cage and use method thereof, the net cage has the lifting and rotating functions, the net cage lifting function can reduce net cage draught and solve the problems of net cage hauling, docking maintenance and adult fish capturing; and the net cage rotating function can achieve net sunning to remove marine organisms and solve the problem that the fishing net is frequently replaced due to marine organism attachment.

Owner:SHANGHAI ZHENHUA HEAVY IND

Planing boat with catamaran three-channel hull

InactiveCN101554918BReduced sailing draftSuppressing wavesHull stemsHydrodynamic/hydrostatic featuresStress concentrationStress Problem

The invention discloses a planing boat with a catamaran three-channel hull. The planing boat is provided with a hull and a board at least. The bottom of the hull is provided with an A trunk bulkhead end surface, a B trunk bulkhead end surface, an A slideway, a B slideway, a C slideway, an A planing surface and a B planing surface; the B slideway is arranged along a central line and is a sector structure; the A planing surface and the B planing surface are arranged at two sides of the B slideway; the A slideway is arranged between the A planing surface and a right trunk bulkhead which is provided with the A trunk bulkhead end surface at the stern; and the C slideway is arranged between the B planing surface and a left trunk bulkhead which is provided with the B trunk bulkhead end surface atthe stern. The catamaran three-channel hull adopts oval channel section conformation to solve the concentrative stress problem of the hull effectively.simultaneously, on the basis of common channel planing boats, the invention adds two outer side channels at two sides of the stern and changes single channel type into three-channel type, thus greatly increasing the width of the stern, not only improving the effective use area of the board, but also enhancing the transversal stability of the planing boat and being capable of reducing the wave making of the boat.

Owner:BEIHANG UNIV

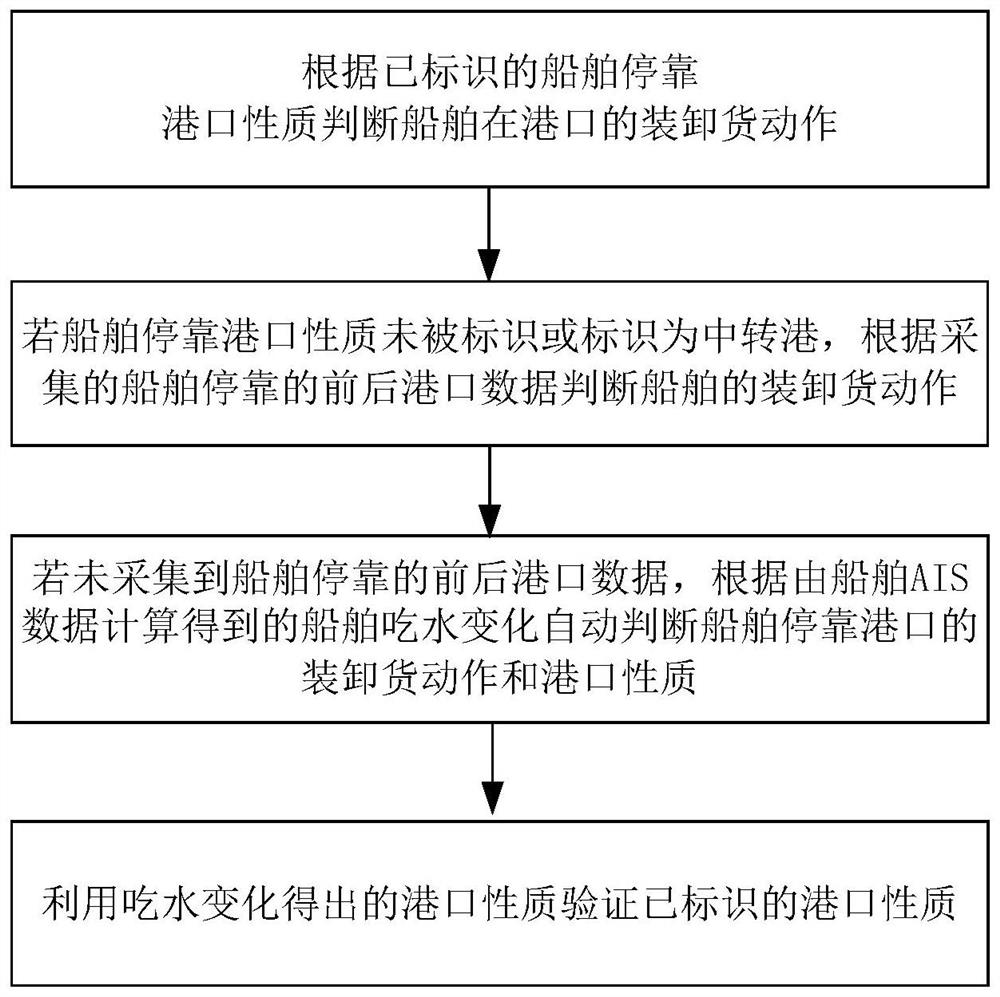

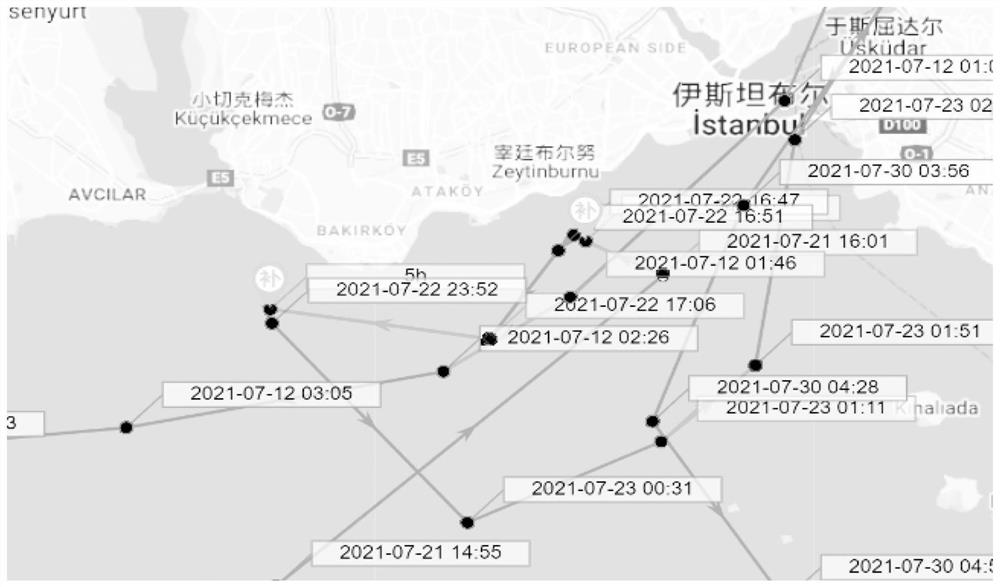

Intelligent identification method and system for ship in-port loading and unloading

PendingCN113935692AAccurate judgmentAccurate monitoringLogisticsMarine engineeringStructural engineering

The invention provides an intelligent identification method and system for ship in-port loading and unloading, and the method comprises the steps that the loading and unloading actions of a ship at a port is judged according to the collected identified ship docking port property, if the port property is identified as a loading port, a condition that the ship is loaded at the docking port is judged, if the property of the ship docking port is not identified or the ship docking port is identified as a transfer port, the loading and unloading actions are judged according to the port data before and after the ship docking, if the ship is unloaded in the port before the ship docking port, the ship is loaded in the ship docking port, and if the port data before and after the ship docking port are not collected, the loading and unloading action of the ship docking port is automatically judged according to the calculated ship draft change, if the draft of the ship is reduced after the ship leaves the berthing port, the ship is judged to be unloaded at the port, and if the draft of the ship is increased after the ship leaves the docking port, the ship is judged to be loaded at the port. By judging loading and unloading, the accurate judgment and monitoring of the whole sailing period of the ship are facilitated.

Owner:COSCO SHIPPING TECH CO LTD

a semi-submersible platform

ActiveCN112078739BReduce weightImprove stabilityWaterborne vesselsFloating buildingsMarine engineeringOffshore oil and gas

The invention discloses a semi-submersible platform, which is mainly suitable for floating offshore oil and gas production platforms, drilling and workover platforms, or living support platforms that do not require high oil storage capacity. The base pontoon floating on the sea is vertically distributed with columns and deck boxes in sequence. The base pontoon, column and deck box are connected as a whole and form a through hole communicating with seawater in the vertical direction. Pool, the semi-submersible platform of the present invention adopts an integral structure, which effectively avoids the air gap problem existing in the conventional column-type semi-submersible platform, can reduce the height of the column, reduce the weight of the platform and the height of the center of gravity, and improve the stability of the semi-submersible platform. The cross-sectional area of the column along the horizontal direction is smaller than the area of any cross-section of the deck box along the horizontal direction. The deck box with the floating design increases the area of the top of the deck box and changes the direction of wave climbing. The large-volume base pontoon further improves the semi-submersible platform. stability.

Owner:CHINA NAT OFFSHORE OIL CORP +1

Container ship assembled crane and its assembly method

InactiveCN106143808BReduce weightBalance weightCargo handling apparatusPassenger handling apparatusEngineeringWinch

Owner:HUAXIA OCEAN ENERGY ENG TIANJIN

Expendable pattern for manufacturing corner fittings of container and manufacturing method and using method thereof

InactiveCN102029358BCasting high added valueSolution to short lifeFoundry mouldsFoundry coresCasting defectElectrical and Electronics engineering

The invention provides an expendable pattern for manufacturing corner fittings of a container. The expendable pattern comprises a casting latex channel, a first expendable pattern and a second expendable pattern, wherein an expendable pattern latex channel is formed on a side external wall of the first expendable pattern; a first through hole and a plurality of grooves are formed on the first expendable pattern; a second through hole and a third through hole are formed on a wall of the second expendable pattern; a plurality of connecting bumps are formed on the second expandable pattern; the grooves and the connecting bumps are in inserted joint; the expendable pattern latex channel and the casting latex channel are in glued and fixed connection; the casting latex channel is prismatic; the connection position of the grooves and the connecting bumps is provided with gummed paper which is glued and fixed with the first expendable pattern and the second expendable pattern. The process is simple; the expandable pattern has a rational pattern structure, low cost and high production efficiency; and the produced corner fittings of the container have smooth surfaces and low casting defect rate.

Owner:青岛顺联集装箱部件制造有限公司

Construction technology of self-propelled semi-submersible ship to ship large immersed tubes

ActiveCN106522275BReduce distanceImprove work efficiencyArtificial islandsUnderwater structuresMarine engineeringPrefabrication

The invention provides a construction process for shipping large sinking pipes by a self-propelled semi-submerged ship for transporting the sinking pipes from a sinking pipe prefabrication factory to a foundation trench region for sinking pipe mounting construction. A mooring and outfitting region is arranged next to the foundation trench region, the semi-submerged ship loads the sinking pipes in a deep dock of the sinking pipe prefabrication factory and transports the same to the mooring and outfitting region, and after an outfitting step of the sinking pipes in the mooring and outfitting region is finished, the sinking pipes are transported to the foundation trench region in a floating manner through a sinking pipe mounting ship and a tug. According to the construction process for shipping large sinking pipes by the self-propelled semi-submerged ship provided by the invention, the floating transportation distance of the sinking pipe is greatly reduced, and the work efficiency of transporting the sinking pipe to 3-4 times; secondly, as draft of the semi-submerged ship which transports the sinking pipes is smaller compared with that of sinking pipe floating transportation in the prior art, the requirement on channel depth is greatly reduced. The channel needs not to be excavated, so that the time and economical costs are further saved; furthermore, the requirements on natural conditions such as a water wave flow by transporting the sinking pipes by the semi-submerged ship are relatively low, the limiting condition of transporting the sinking pipes is reduced, and the work efficiency of transporting the sinking pipes is further improved.

Owner:NO 2 ENG CO LTD OF CCCC FIRST HARBOR ENG +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com