Method for manufacturing automobile cross beam lost foam and using method

A manufacturing method and lost foam technology, applied in the direction of manufacturing tools, casting molding equipment, casting molds, etc., can solve the problems of the use of lost foam technology automobile beams, improve mechanical properties and surface finish, eliminate cleaning, and reduce casting defects. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

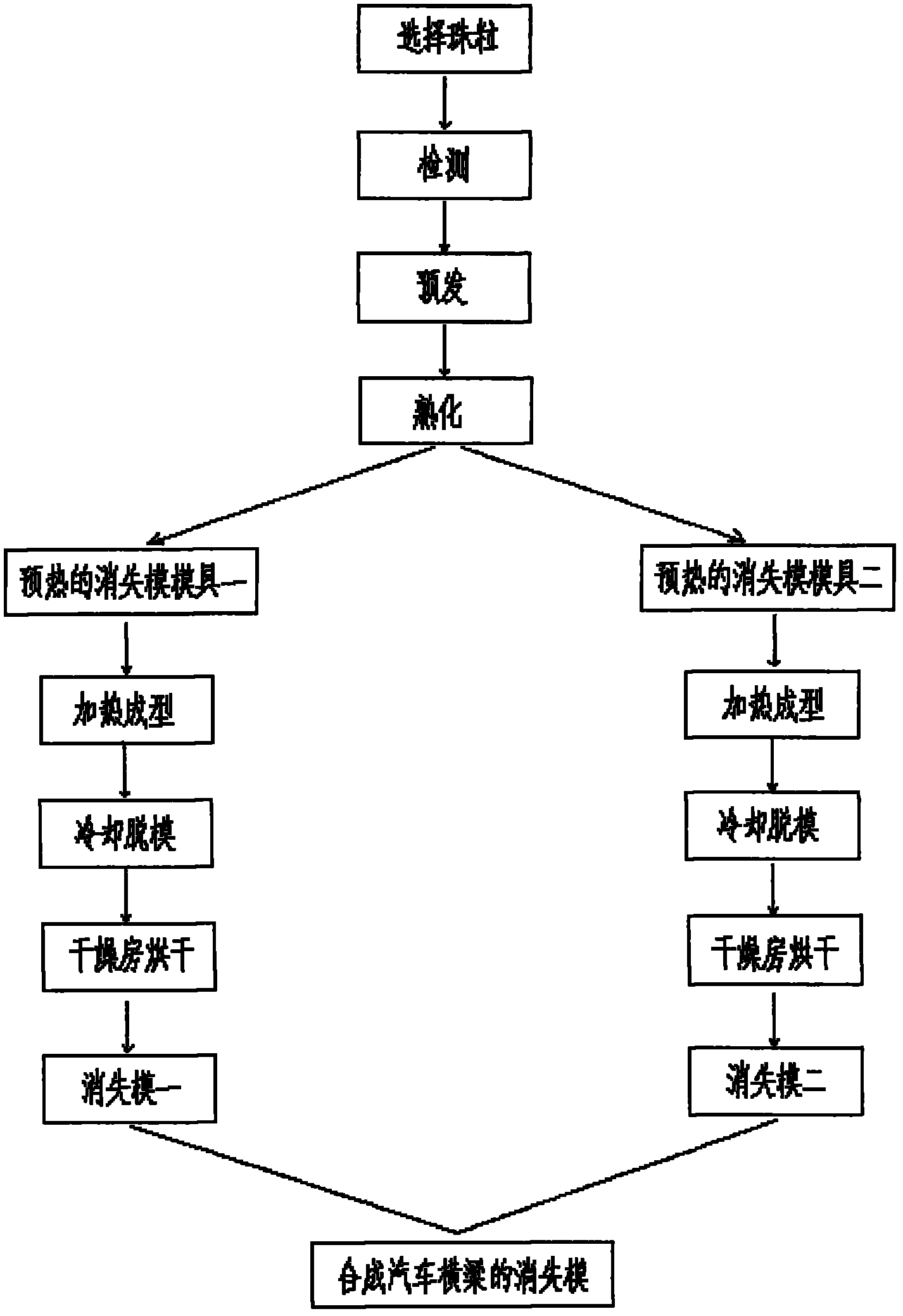

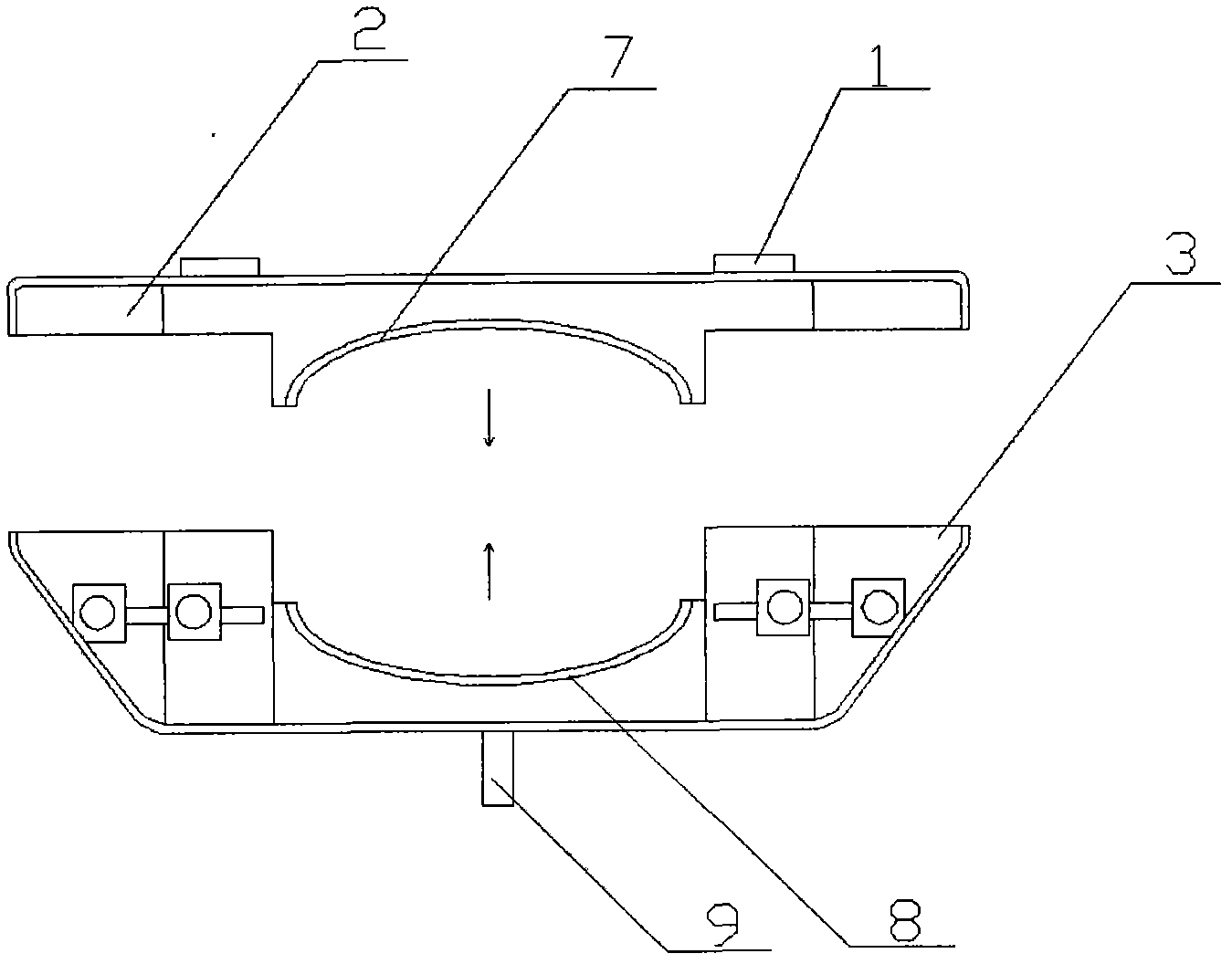

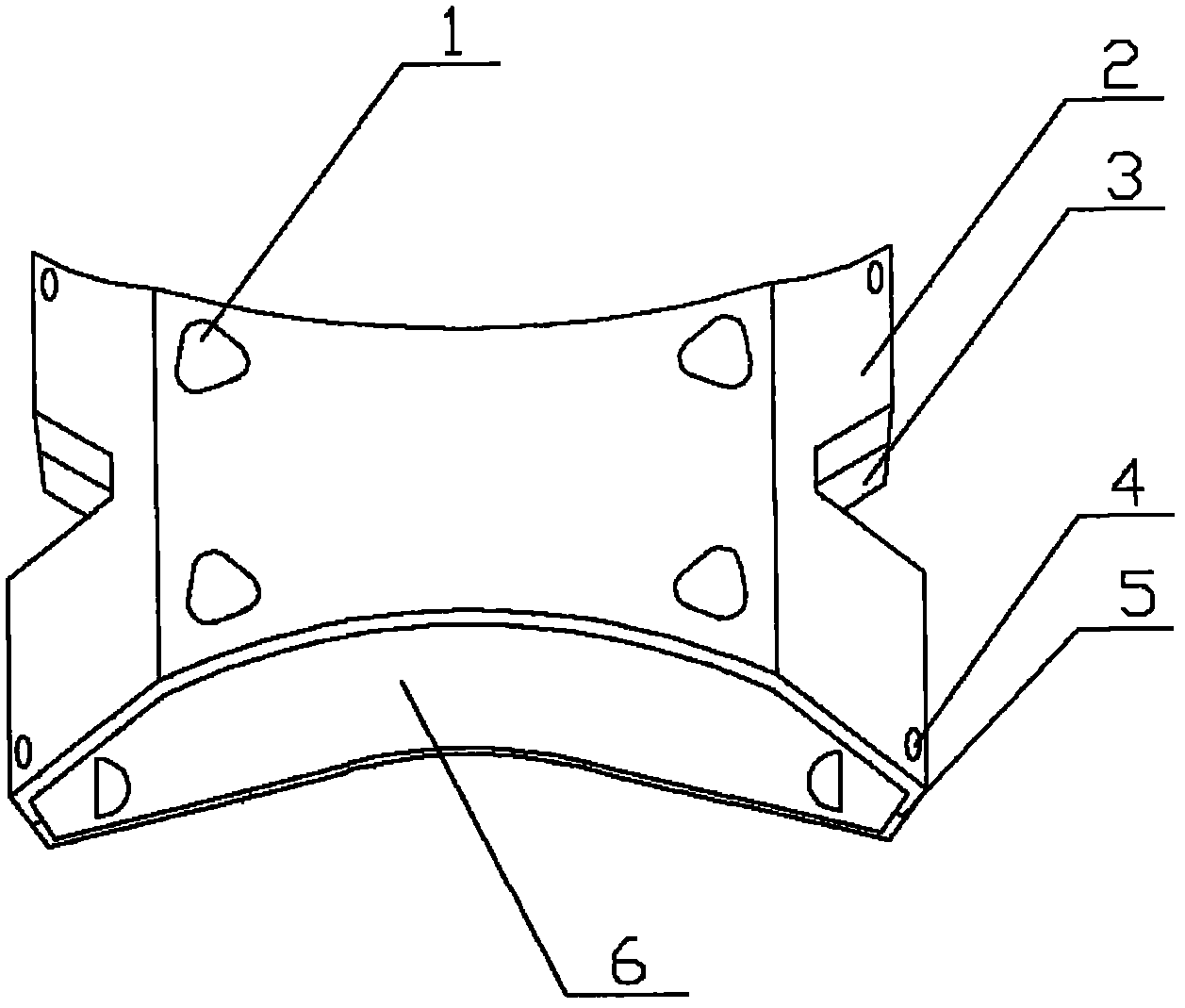

[0046] Such as Figure 1-Figure 3 as shown, figure 1 It is a flow chart of the manufacturing method of the lost foam of the automobile beam in the present invention. figure 2 It is a side view of the lost mold of the automobile beam made by the manufacturing method of the present invention. image 3 It is a three-dimensional schematic diagram of the lost mold of the automobile crossbeam produced by the manufacturing method of the present invention. The manufacturing method of automobile beam lost foam among the present invention, as figure 1 shown, including the following steps:

[0047] a. Select the appropriate STMMA beads: select the diameter of the beads in the range of 0.45-0.60mm, and detect the moisture and volatile content of the beads;

[0048] b. Pre-generating: The intermittent steam pre-generating machine first passes through the steam-water separation device to fully remove excess water in the machine, and then sends the STMMA beads into the intermittent steam ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com