Hull structure with underwater appendage

A technology of underwater attachment and hull, applied in the field of high-performance ships, can solve problems such as hindering the development of high-performance ships, reducing the comfort of passengers on board, and prone to violent turbulence, etc., to improve propulsion efficiency, improve maneuverability, and facilitate installation. and maintenance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

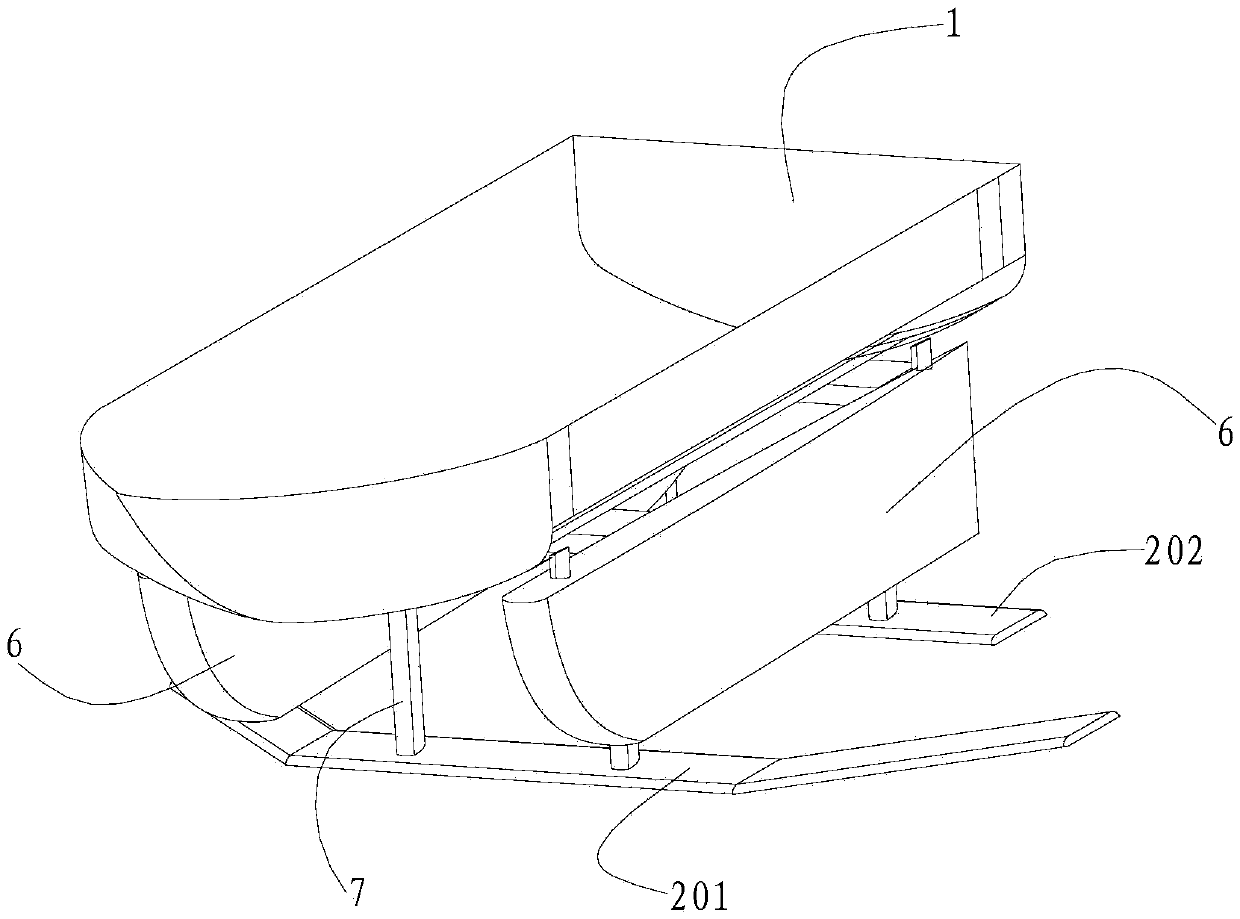

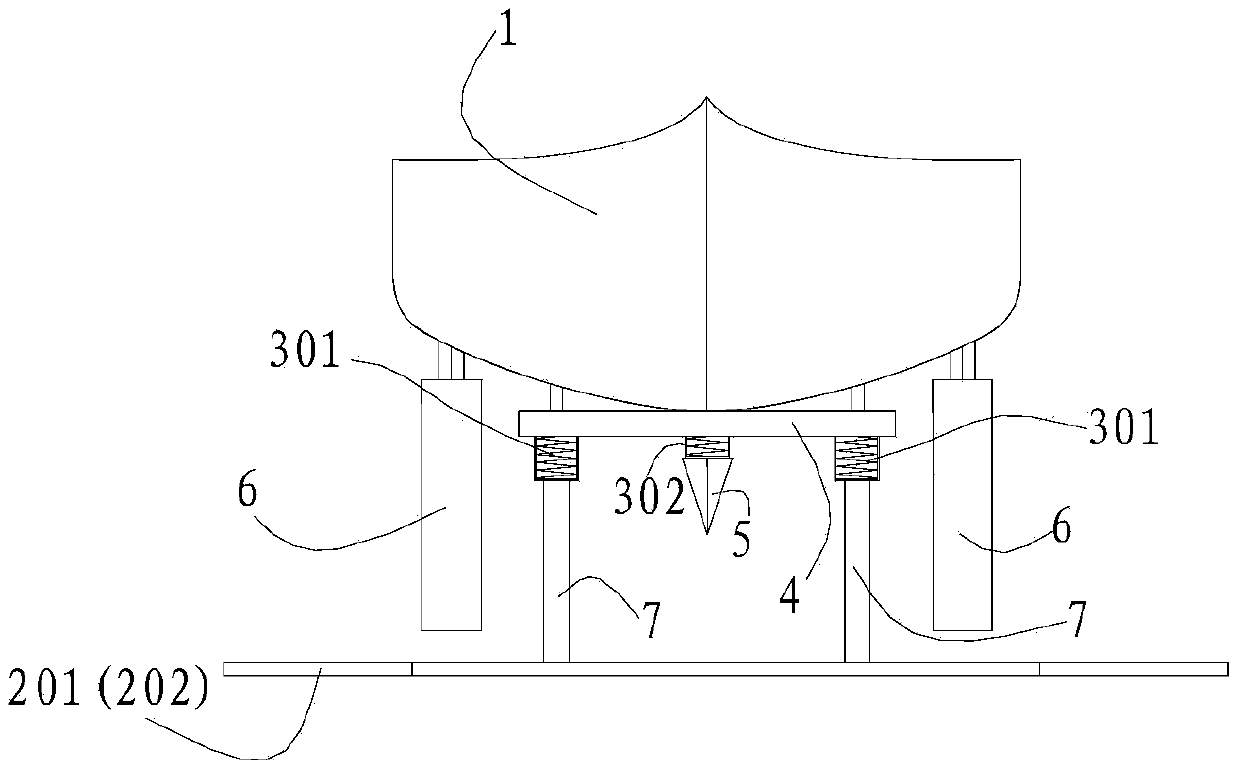

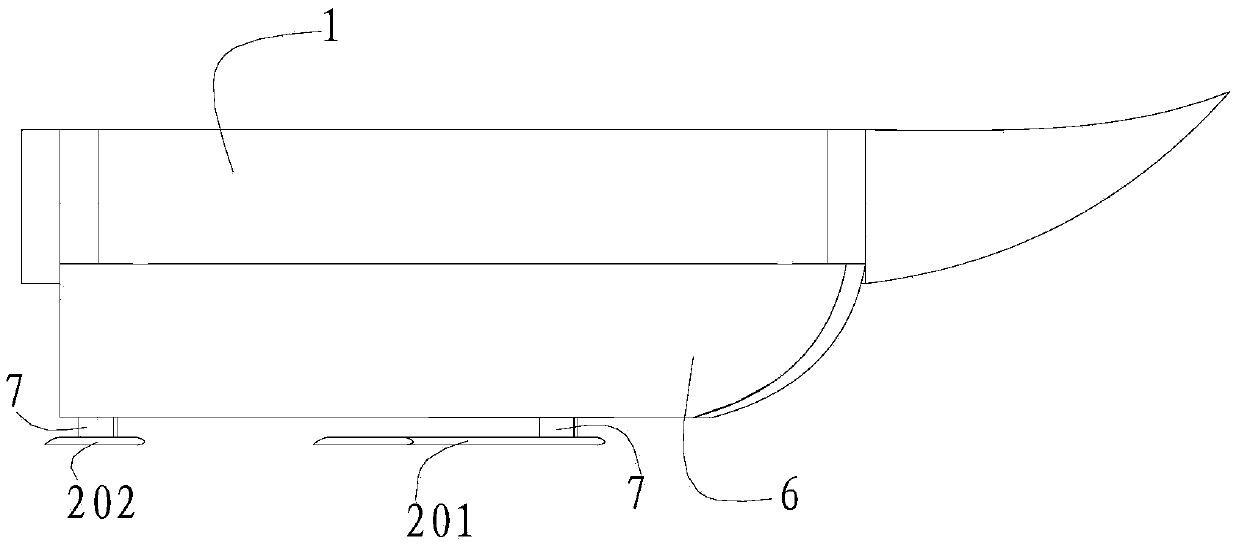

[0053] Such as Figure 1-10 As shown, a hull structure with an underwater appendage includes a hull 1 and an underwater appendage arranged below the hull 1, and a suspension device is arranged between the hull 1 and the underwater appendage. In this embodiment, the underwater appendage includes an appendage, a connecting shaft 203 connecting the appendage and the suspension device 301, wherein the appendage includes a front hydrofoil 201 arranged below the middle of the hull 1 and a hydrofoil 201 arranged below the tail of the hull 1. The rear hydrofoil 202 and the front hydrofoil 201 are swept-back hydrofoils, and the front hydrofoil 201 is longer than the rear hydrofoil 202 . The connecting shaft 203 is sleeved with a streamlined pillar 7 that can rotate relative to the connecting shaft 203 . The structure is simple, adopting the structural form of double hydrofoils, and the arrangement form is an aircraft layout, which improves the maneuverability and operability of the hyd...

Embodiment 2

[0060] Such as Figure 12 As shown, the difference between this embodiment and Embodiment 1 lies in the installation position of the chassis 4: the hull 1 is arranged on the suspension device 301, the chassis 4 is arranged below the suspension device 301, and the front hydrofoil 201 and the rear hydrofoil 202 are arranged On chassis 4. The front hydrofoil 201, the rear hydrofoil 202, the suspension device 3, and the chassis 4 form a modular structure that can be used to place and support the hull 1. In application, the hull 1 only needs to be placed on the suspension device 301 and supported by the chassis 4. The hull 1 can be transformed into a hydrofoil boat with fast speed, good seakeeping performance and high comfort for passengers in the hull, which is convenient for popularization of the hydrofoil boat. In addition, installing the chassis 4 under the hull 1 is more convenient for the installation and maintenance of the hydrofoil structure 2 and auxiliary facilities.

...

Embodiment 3

[0063] Such as Figure 13-16 As shown, the difference between this embodiment and Embodiment 1 is that no flat buoy 6 is set in this embodiment, but a triangular buoy 8 arranged along the direction of the hull is symmetrically arranged on both sides of the hull 1, and the triangular buoy 8 of the triangular buoy The section is triangular, and the section of the triangular buoy 8 and the hull 1 is trapezoidal, and only a single hydrofoil 204 is provided in this embodiment. The triangular buoy 8 presents an airfoil feature with a certain length along the direction of the hull, which can produce ground effect when the ship is sailing, which increases the lift of the ship, reduces the draft of the ship, and then reduces the resistance of the ship and improves the performance of the ship. For propulsion efficiency, the reduction in draft also raises the hull 1, which in turn reduces the action of waves.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com