Special lifting and vibration-driving ship for integrated driving of cell type steel sheet pile large cylinders and vice cells

A technology of large cylindrical auxiliary grid and grid-shaped steel sheet pile, which is applied to the direction of sheet pile walls, cranes, special-purpose ships, etc., can solve the problems of inability to complete the hoisting and vibration of a large cylindrical auxiliary grid of grid-shaped steel sheet piles, and achieve Meet site height limit requirements, low height, and large outboard lifting distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

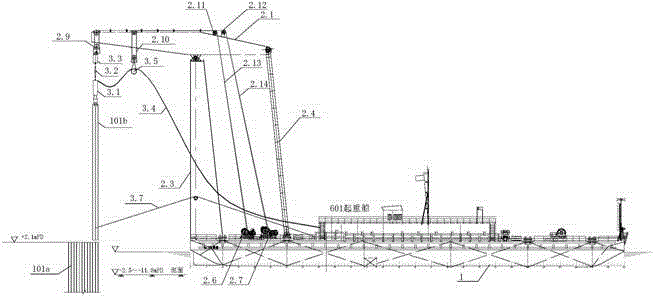

[0040] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

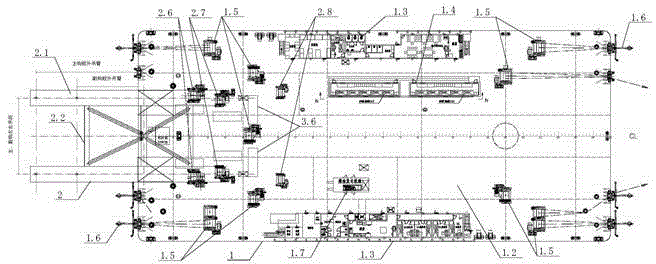

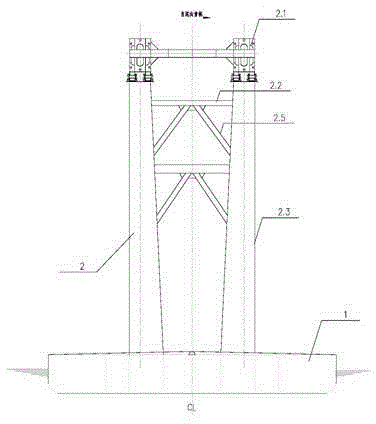

[0041] In this example, a "special lifting and vibrating shipwreck" is provided for carrying out on-site dredging and hoisting vibratory hammers and auxiliary grid sheet piles.

[0042]According to factors such as aviation height limit, seabed mud surface elevation, vibratory hammer lifting height, hoisting process requirements for steel sheet pile assembly pieces in the lower section of the sub-cell and hull stability requirements, therefore, in this example, the sub-cell is dedicated to lifting and vibrating The sunken ship uses a 6,000t-class deck barge as a special crane mother ship.

[0043] The special hoisting and hoisting vessels for whole driving can minimize the height of the slings, so that the length of the lower piles can be as long...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com