Expendable pattern for manufacturing corner fittings of container and manufacturing method and using method thereof

A lost foam and container technology, applied in manufacturing tools, casting equipment, molds, etc., can solve problems such as the use of lost foam technology container corners, improve mechanical properties and surface finish, eliminate cleaning, and reduce casting defects. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

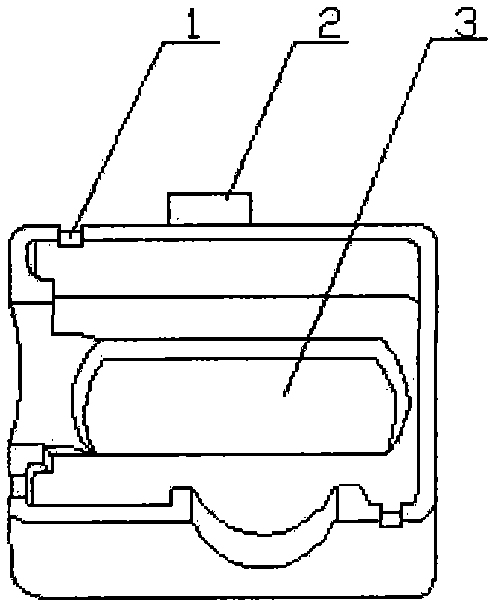

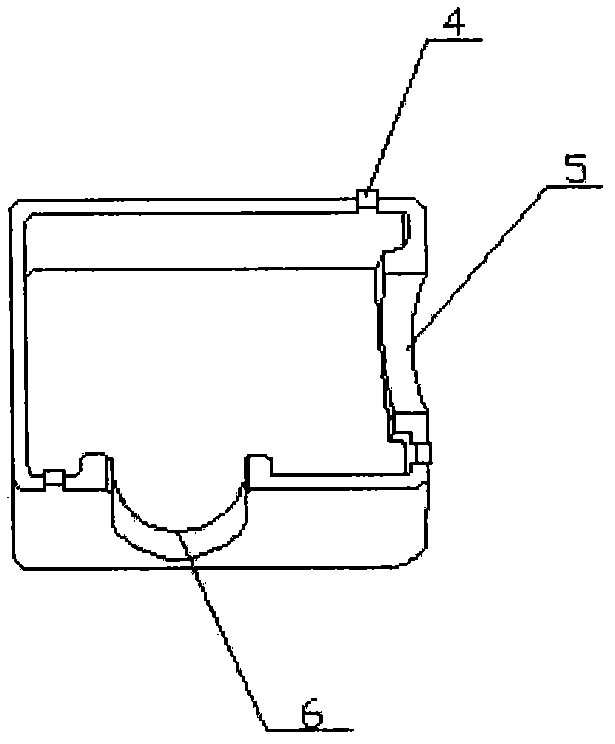

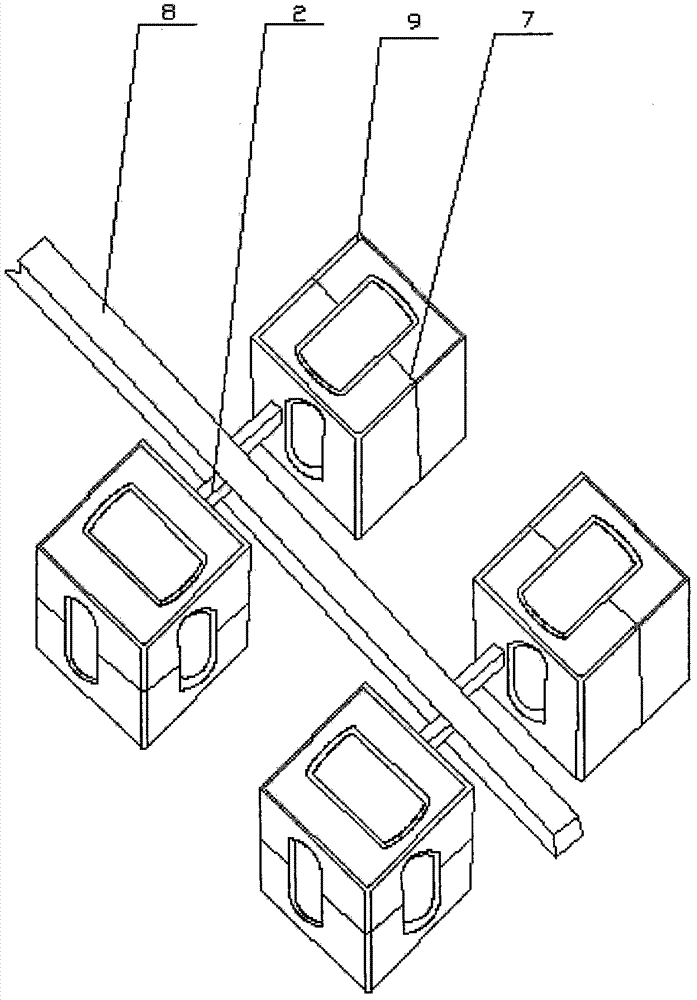

[0050] Such as figure 1 and figure 2 as shown, figure 1 It is a schematic diagram of the lost mode 1 in the present invention. figure 2 It is a schematic diagram of the lost mode 2 in the present invention. Among them, it includes the casting rubber channel 8, the first lost foam and the second lost foam, the outer wall of the first lost foam is provided with the rubber channel 2 of the lost foam, the first through hole 3 is arranged on the first lost foam, and the first through hole is further provided There are several grooves 1, the second through hole 5 and the third through hole 6 are provided on the wall of the lost foam two, and a number of connecting protrusions 4 are further arranged on the lost foam two, and the grooves 1 and the connecting protrusions 4 are inserted combined connection. The lost foam rubber channel 2, the first through hole, the groove and the lost foam one are integrally formed during manufacture; the connecting protrusion 4, the second throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com