Large transport ship

A transport ship, large-scale technology, applied in the direction of transportation and packaging, hull, ship accessories, etc., can solve the problems of reduced propulsion efficiency, deterioration of maneuverability, increased load changes of propellers and main power units, etc., to achieve the effect of easy construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The invention relates to large transport ships with a displacement of more than 1000 tons such as oil tankers, bulk cargo ships, container ships, liquefied natural gas ships and car carriers, especially large transport ships that do not need ballast water. Refer to each embodiment below Figure 1 to Figure 11 Description is made, but of course the present invention is not limited to these examples.

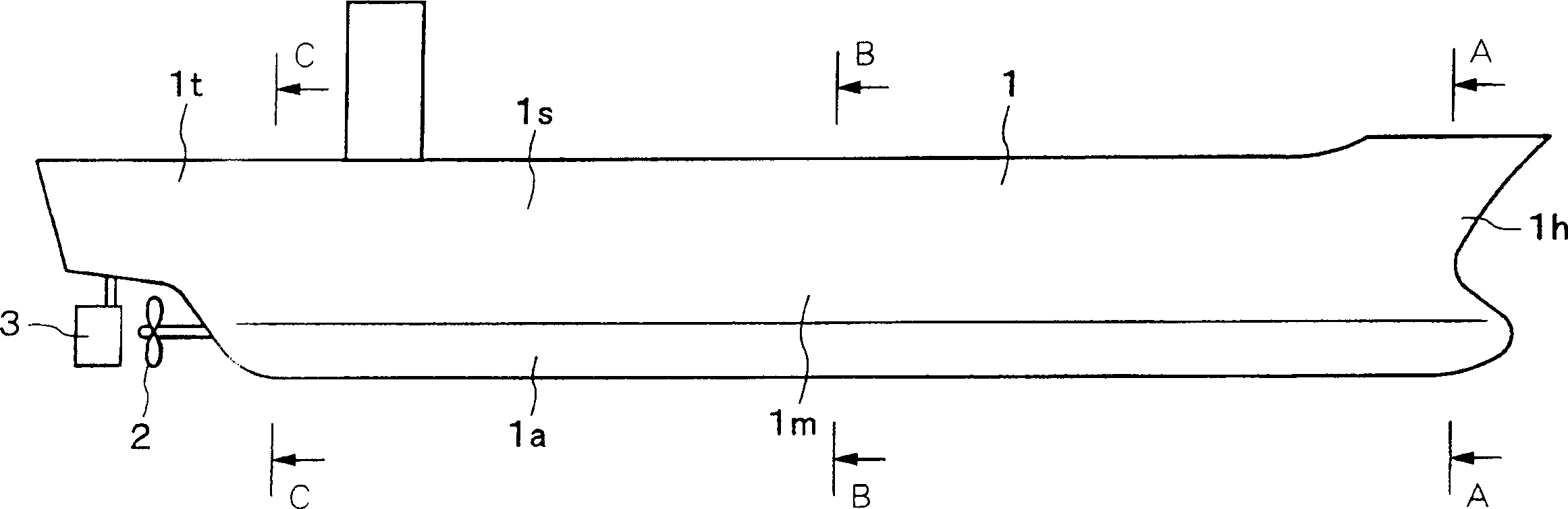

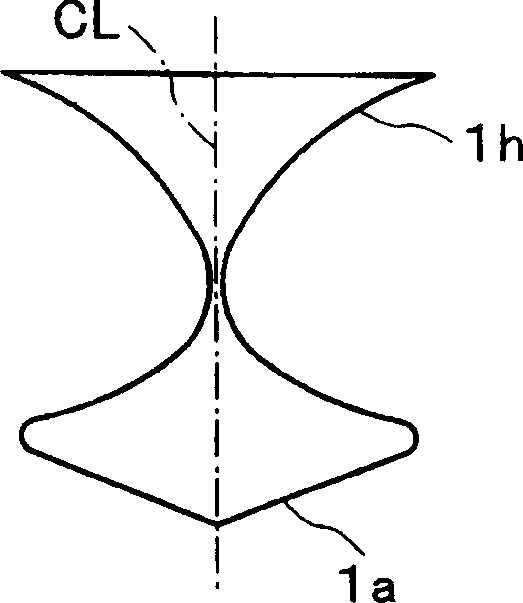

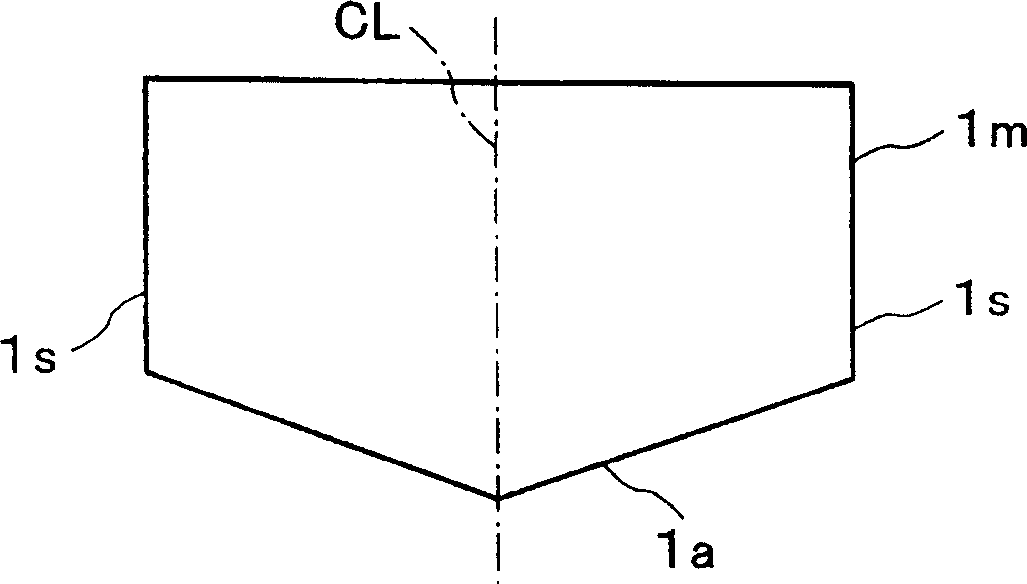

[0047] First, refer to Figure 1 to Figure 4 Example 1 of the present invention will be described below. figure 1 It is a side view showing the large transport ship of this embodiment. In addition, Fig. 2(a), Fig. 2(b), and Fig. 2(c) are diagrams showing the large transport ship, wherein Fig. 2(a) is figure 1 The A-A sectional view, Figure 2(b) is figure 1 The B-B sectional view, Figure 2(c) is figure 1 The C-C section diagram. image 3 It is a view showing the fully loaded state of this large transport ship, and is a cross-sectional view seen from the same cross-sect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com