Method and apparatus for towing offshore wind turbines

A technology of wind turbines and buoyancy, which is applied in the assembly of wind turbines, the configuration of installing/supporting wind turbines, wind turbines, etc., which can solve the problems of increasing the cost of transporting wind turbines, limiting route selection and installation locations, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

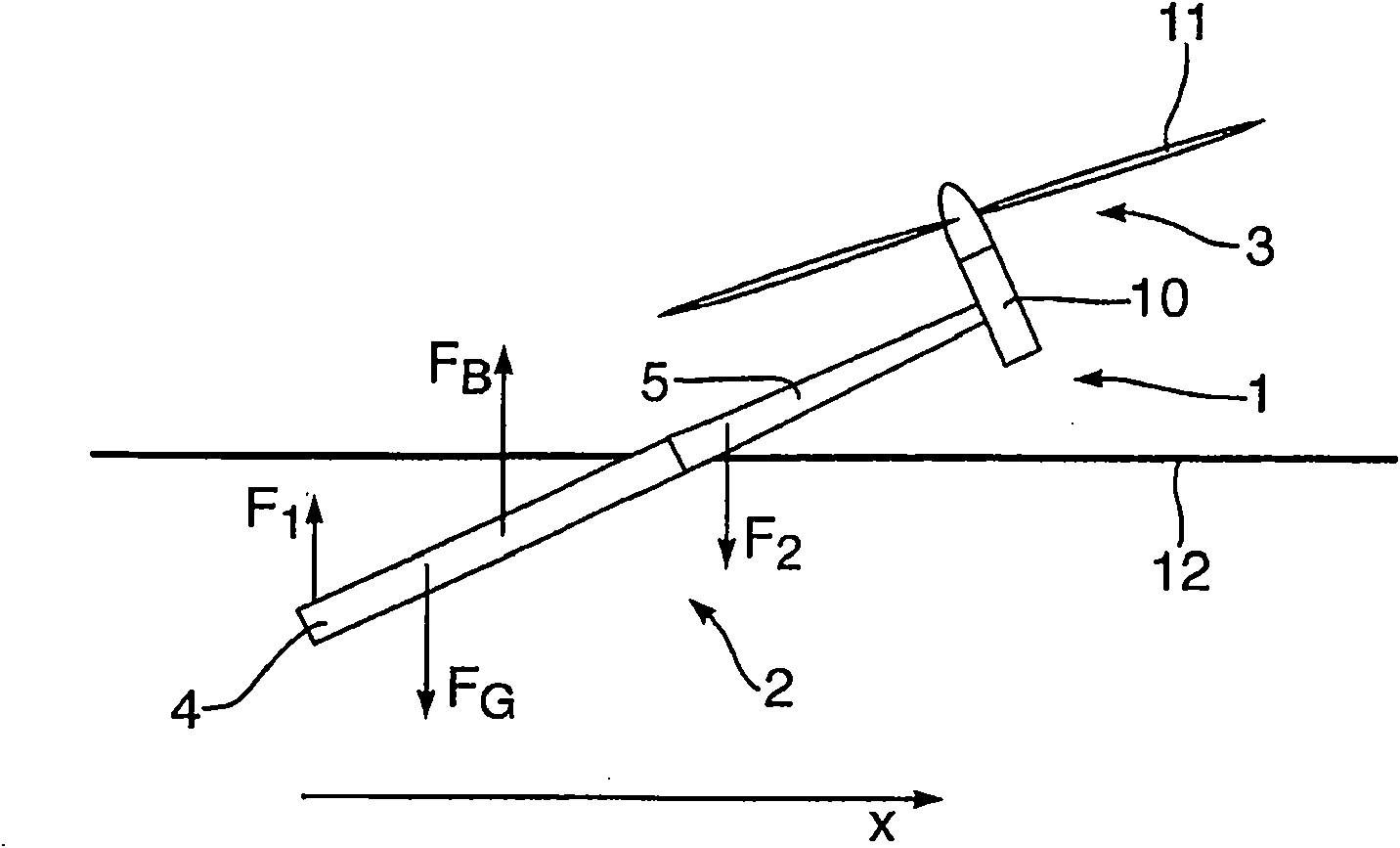

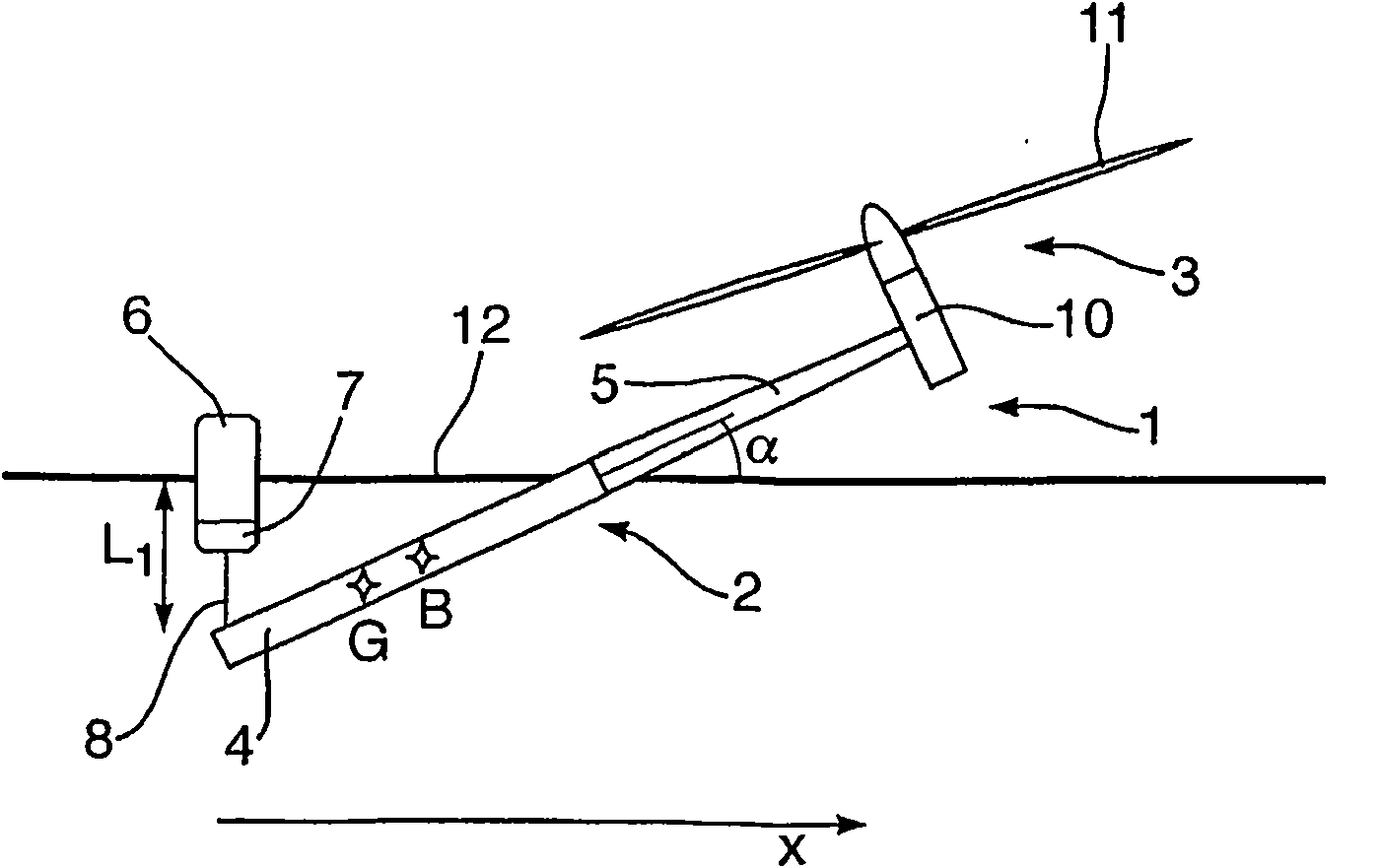

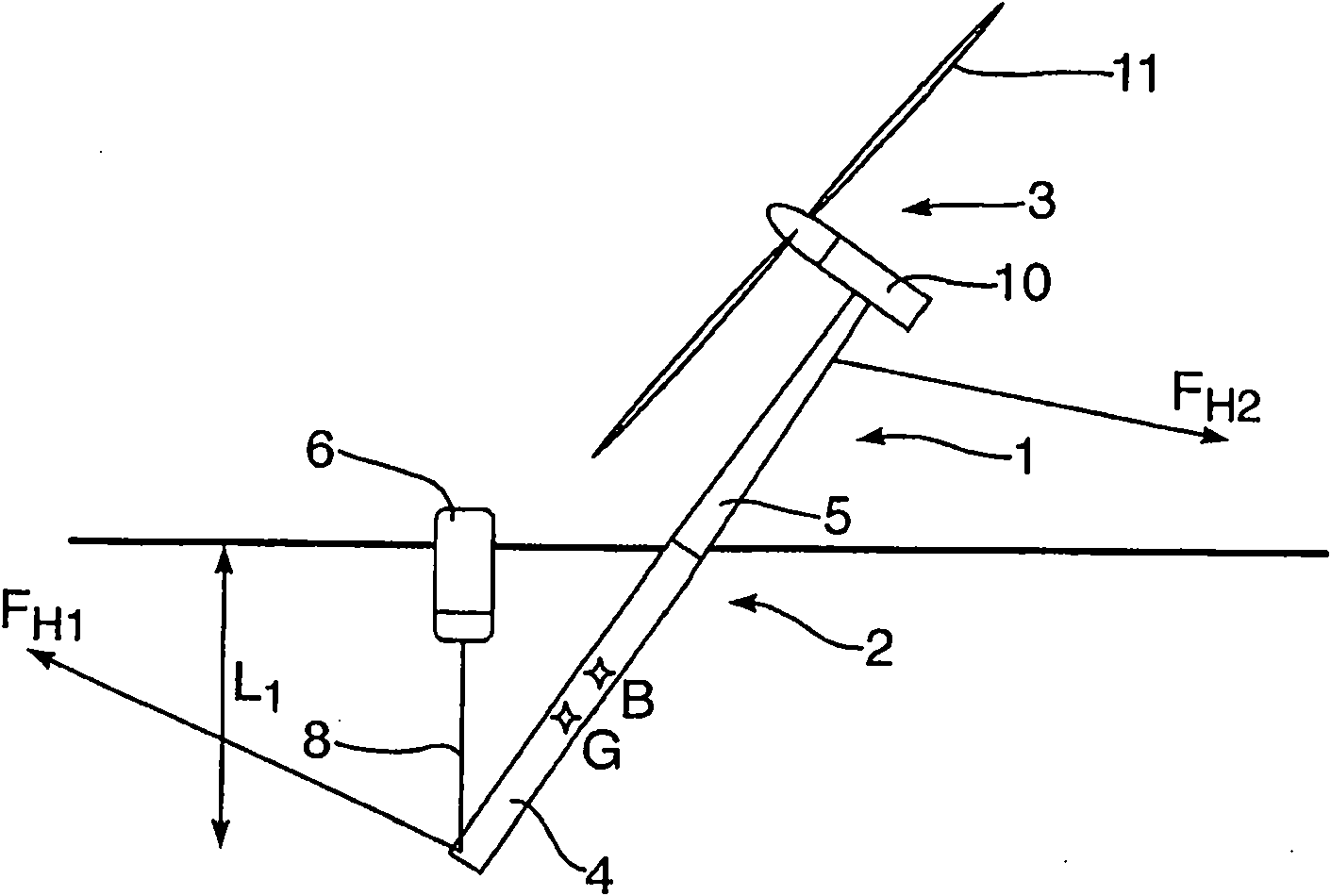

[0030] figure 1 The forces acting on a preferred embodiment floating wind turbine (hereinafter "wind turbine") 1 in a tilted position are shown. The wind turbine 1 comprises a support structure 2 and a wind turbine generator 3 . The support structure 2 comprises a lower support structure 4 and a tower 5 . The wind turbine generator 3 comprises a nacelle 10 and a rotor 11 . f G is the gravity of wind turbine 1. f B is the buoyancy of wind turbine 1.

[0031] To keep the wind turbine 1 in a tilted position, an upwardly directed force F is required 1 . like figure 1 Shown, F 1 It should act from a position on the lower support structure 4 below the center of gravity of the wind turbine 1 . Optionally, a downwardly directed force F acting above the center of buoyancy 2Can also be applied to wind turbines 1 .

[0032] The inclined floating position of the wind turbine 1 should be stable. This requires a stable balance of forces and moments in a vertical plane passing t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com