Telescopic propeller system capable of being maintained in ship

A propeller, telescopic technology, applied in ship propulsion, propulsion components, propulsion engine and other directions, can solve the problems of increasing the resistance of ships or marine engineering, increasing the cost of sea migration, increasing the cost of project construction, etc., and achieves a small draft and is convenient. Maintenance and efficiency improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

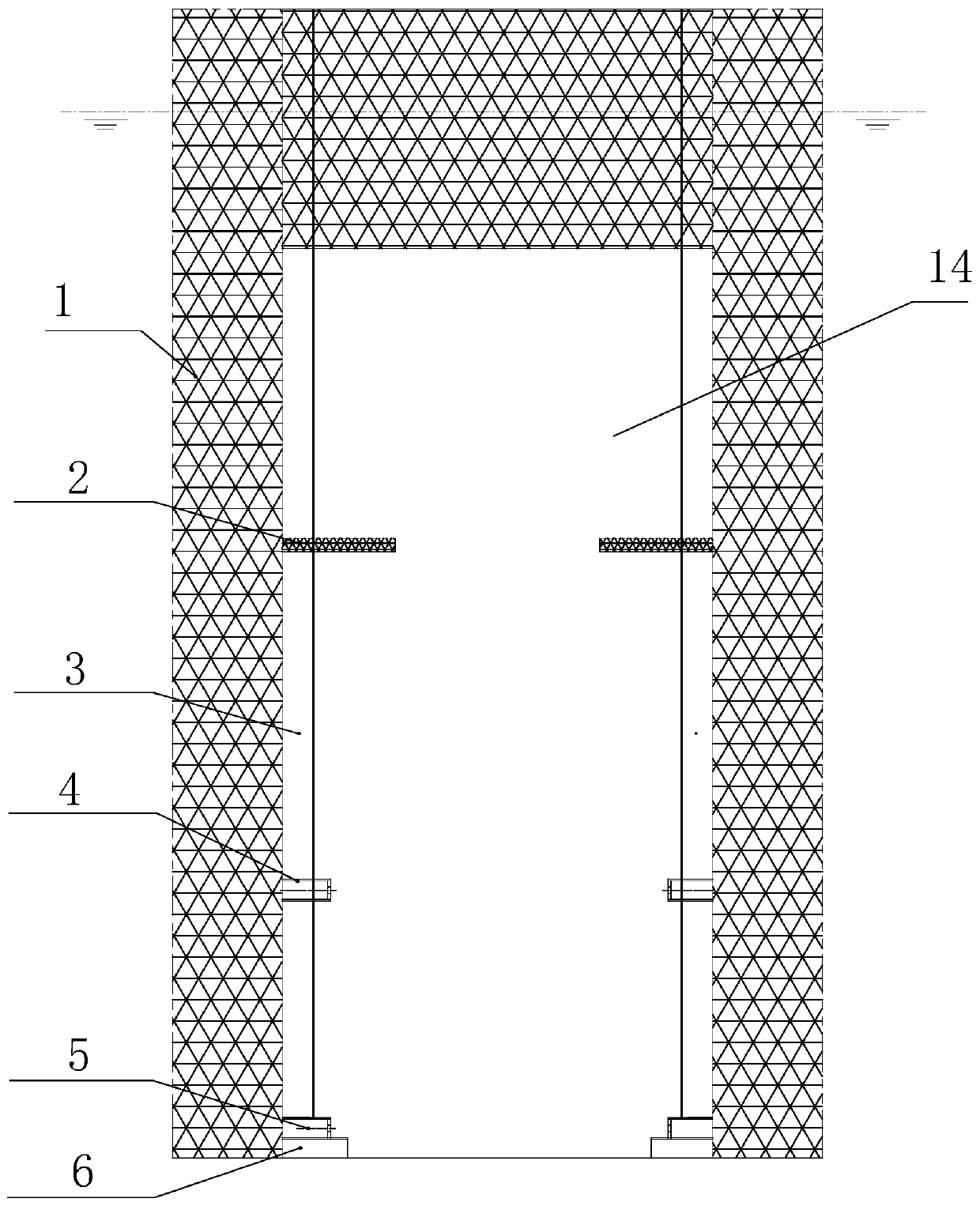

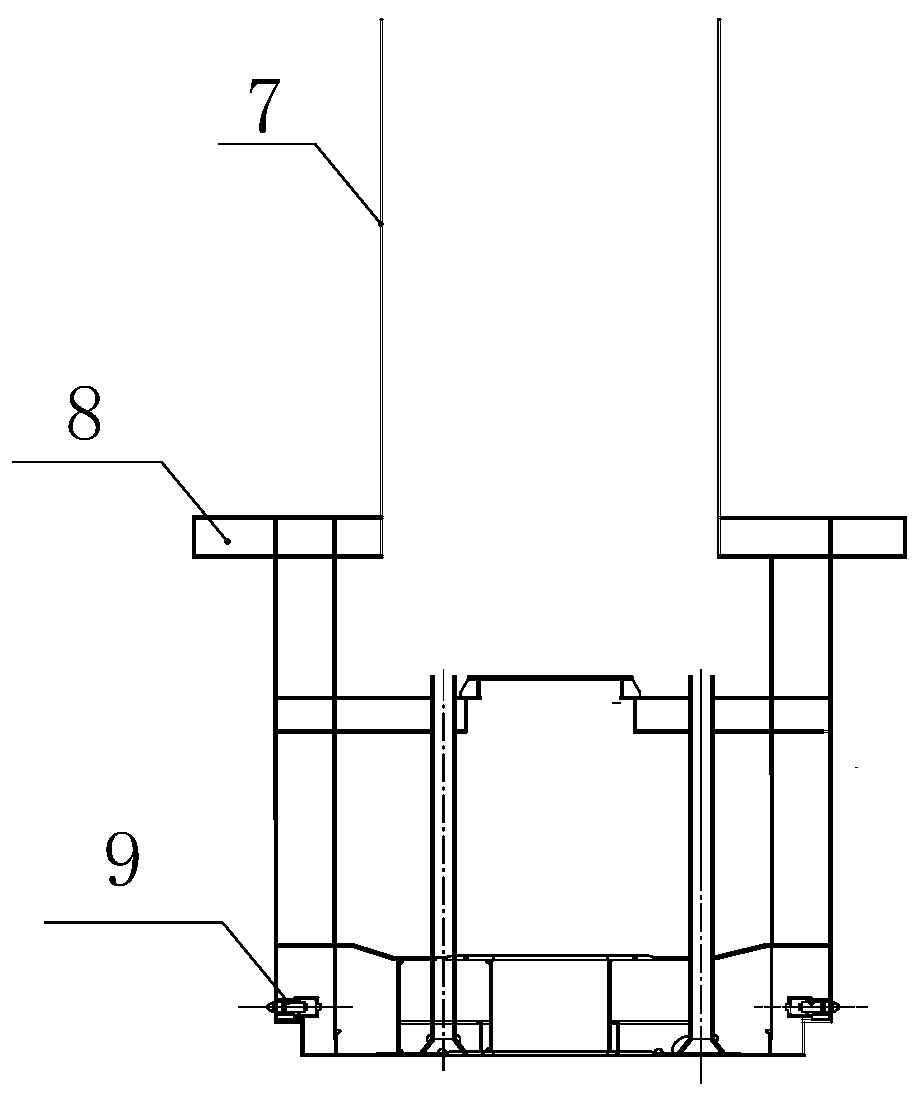

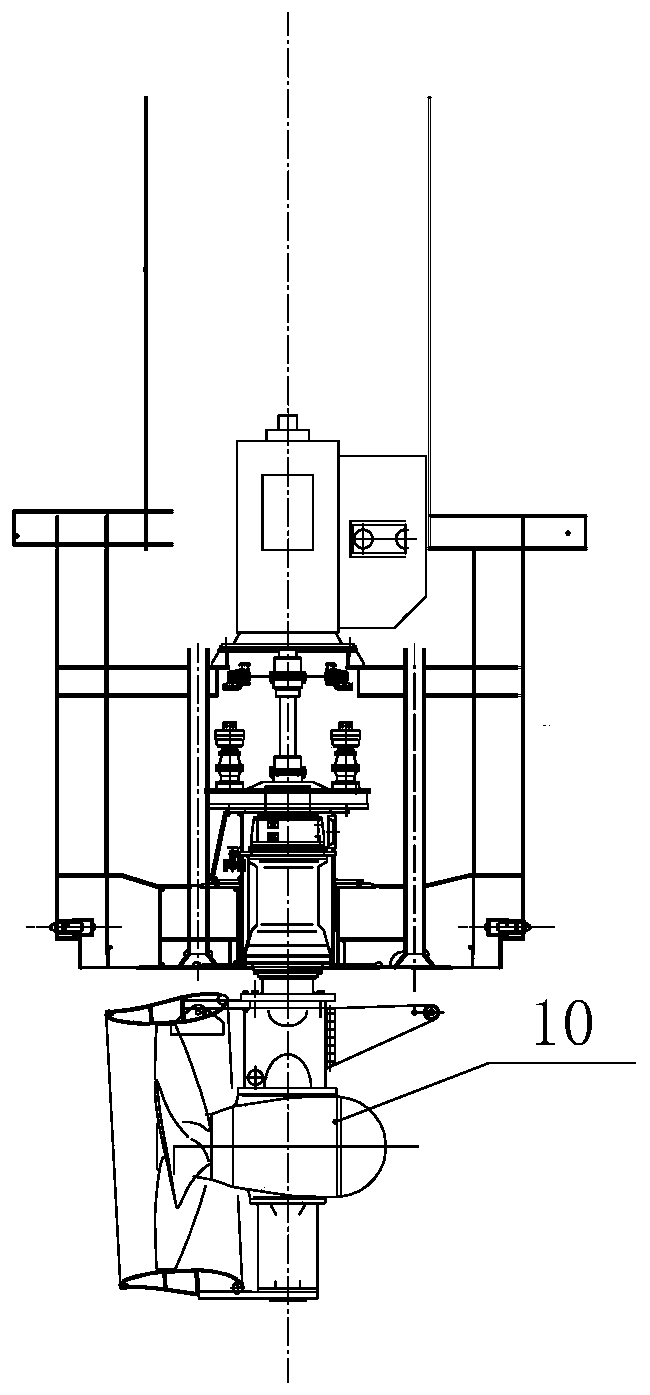

[0037] Such as Figure 1 to Figure 7 As shown, first dig out a space for installing the propeller and structural box in the hull structure 1 where the propeller is installed, which is the propeller installation area 14; this space can be a circular section or a polygonal section , the content of the present invention will take the four-shaped section as an example, and the scheme of using other sections is basically the same as the content of the present invention.

[0038] This space will be used for the storage of the propeller and the structural box body, which are recovered into the hull by the hydraulic lift cylinder 11 when they are not working. Therefore, this space needs to meet the requirements that all propellers and structural boxes can be recovered to the interior of the hull for storage; in addition, necessary seawater pumps ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com