Manganese dry battery and manganese dry battery manufacturing method

A technology of manganese dry battery and battery cartridge, which is applied in the field of manganese dry battery, can solve the problem of not being able to completely prevent the perforation of the zinc cartridge, and achieve the effect of excellent corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

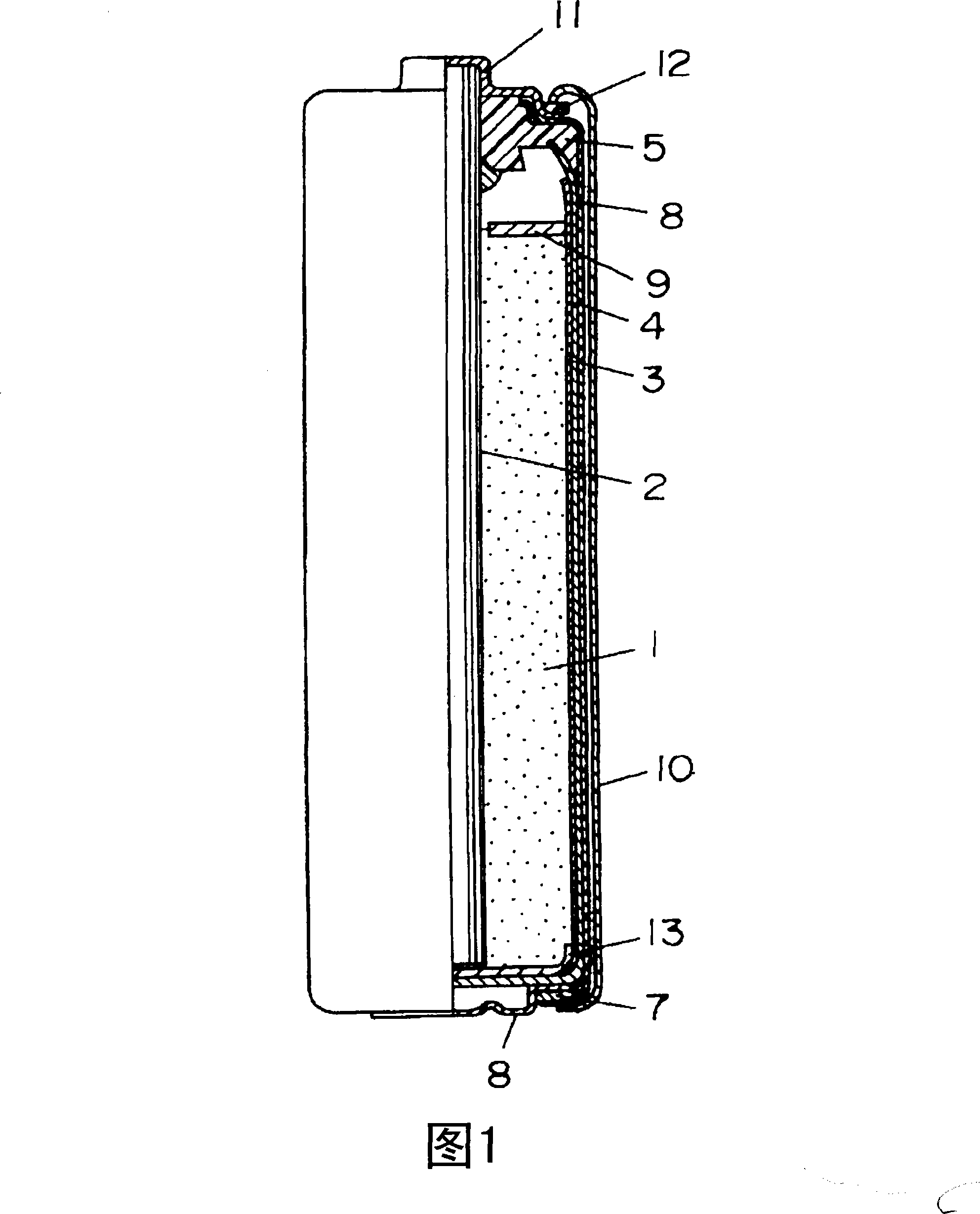

[0047] 1 is a cross-sectional view showing the structure of a manganese dry battery according to a first embodiment of the present invention, and the battery can is composed of a negative electrode zinc can 4 .

[0048] As shown in FIG. 1 , in a bottomed cylindrical negative electrode zinc cylinder 4 , a positive electrode mixture 1 is accommodated through a separator 3 containing an electrolyte solution, and a current collector, namely a carbon rod 2 , is inserted in the center of the positive electrode mixture 1 . Also, the upper opening of the negative zinc cylinder 4 is sealed by the sealing body 5 , the carbon rod 2 passes through the central hole of the sealing body 5 and contacts the positive terminal 11 , and the negative terminal 6 is installed at the bottom of the negative zinc cylinder 4 . In addition, the outer peripheral surface of the negative electrode zinc cylinder 4 is covered with a resin tube 8 , and an outer packaging tube 10 is mounted on the outside of the...

no. 2 approach

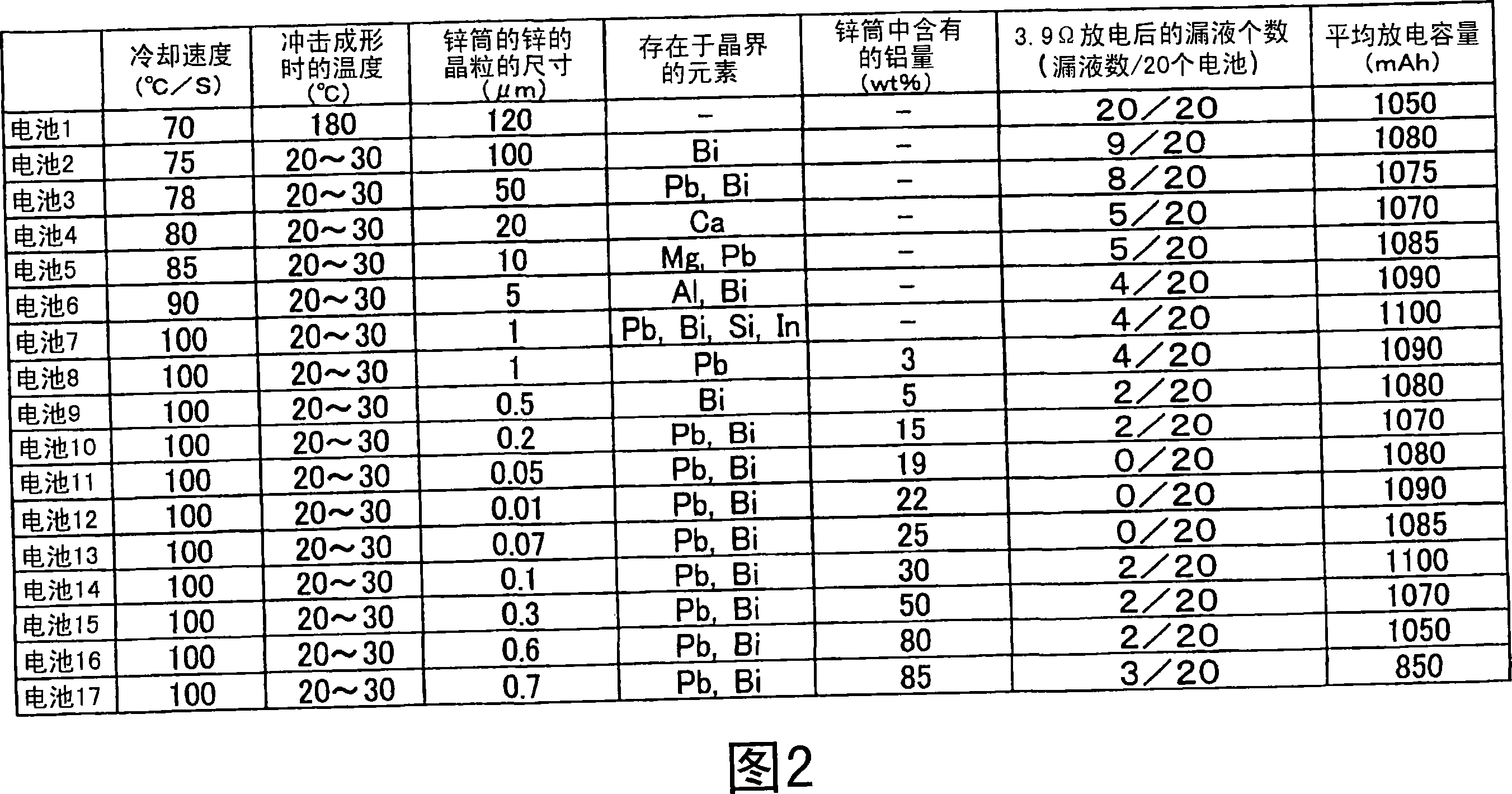

[0058] In the first embodiment of the present invention, the reaction of zinc is uniformized by precipitating additive elements other than zinc at the grain boundaries of zinc, and the crystal grain size of zinc is reduced by one When the number of digits or more is higher, the reaction of zinc can be made uniform.

[0059] That is, the negative electrode zinc can 4 used in the manganese dry battery according to this embodiment is characterized in that the negative electrode zinc can 4 is formed of a zinc plate cast after cooling molten zinc containing aluminum, and the The range of aluminum contained in molten zinc is 3 to 80% by weight.

[0060] When the molten zinc containing the above-mentioned amount of aluminum is rapidly cooled, the crystal grain size of the zinc constituting the zinc cylinder can be set to a fine particle size of about 0.01 to 1 μm. As a result, it is possible to realize a zinc cylinder having a crystal grain size reduced by more than one digit compar...

Embodiment

[0069] Next, the results of evaluating the corrosion resistance of the manganese dry battery according to the present invention will be described based on examples. In addition, this invention is not limited by the following Examples.

[0070]

[0071] A. Manufacture of zinc cylinder

[0072] This mixture in which 1000 ppm of Pb was added to zinc having a purity of 99.99 wt % was melted at a temperature of about 500° C. using a melting furnace to obtain molten zinc. In addition, the molten zinc is cooled to 180°C to 200°C at a cooling rate of 70°C / S, and then pressed into a plate shape with a specified thickness and punched with a press to obtain a circular tablet of a specified size. . By coating the small piece with graphite powder as the main component of lubricant or lubricant containing zinc stearate, and putting them into the mixer for stirring, the lubricant is coated on the surface of the zinc round small piece . Then, a bottomed cylindrical single 3 type (R6 siz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com