Heat stamping apparatus used for quenching control

A technology of hot stamping and hot stamping die, which is applied in the field of hot stamping, can solve the problem of uniform distribution of surface temperature of formed parts, and achieve the effect of uniform distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

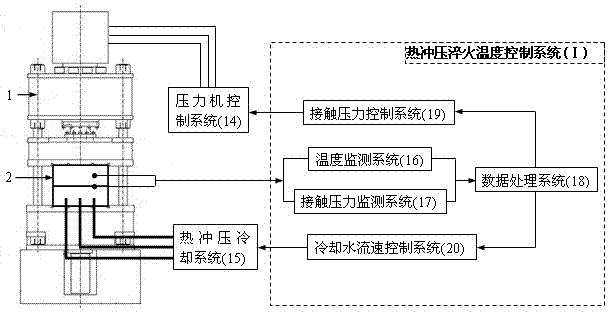

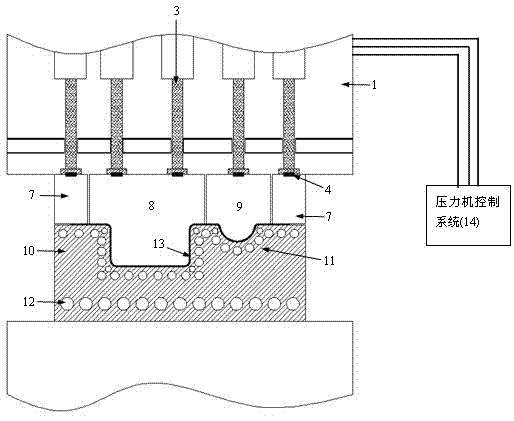

[0031] Such as figure 1 As shown, a hot stamping quenching temperature control system of the present invention and its supporting pressure control device are mainly composed of a servo press 1, a press control system 14, a hot stamping cooling system 15, a hot stamping die 2 and a hot stamping press The quenching temperature control system I is composed; the hot stamping quenching temperature control system I includes a temperature monitoring system 16, a contact pressure monitoring system 17, a data processing system, a contact pressure control system 19 and a cooling water flow rate control system 20.

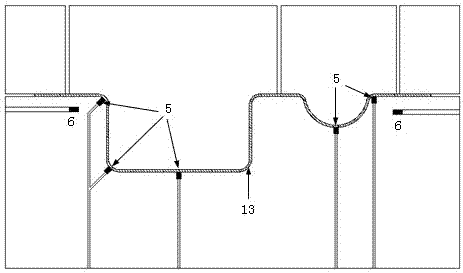

[0032] Such as figure 2 As shown, taking a specific shaped part as an example to illustrate the arrangement of relevant thermocouples;

[0033] The thermocouple 5 used to measure the temperature of the formed part 13, because the highest temperature point and the lowest temperature point in the formed part 13 must be measured, and the bottom surface of the characteristic st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com