La-Mg-Ni series hydrogen storage alloy for low-temperature nickel-hydrogen battery and preparation method of La-Mg-Ni series hydrogen storage alloy

A technology for nickel-hydrogen batteries and hydrogen storage alloys, applied in the negative electrode materials of nickel-hydrogen batteries, La-Mg-Ni hydrogen storage alloys for low-temperature nickel-hydrogen batteries and their preparation fields, can solve problems such as unsatisfactory cycle life, and achieve Convenient operation, simple process, high and low temperature electrochemical performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] La 0.65 Ce 0.1 Mg 0.25 Ni 3 co 0.5 Preparation of alloy powders, including:

[0037] (1) According to La 0.65 Ce 0.1 Mg 0.25 Ni 3 co 0.5 Composition atomic ratio (that is: in the alloy, the atomic percentage of La is 14.44%, the atomic percentage of Ce is 2.22%, the atomic percentage of Mg is 5.56%, and the atomic percentage of Ni is 66.67%, The atomic percentage of Co is 11.11%) and put into an alumina crucible after weighing.

[0038] (2) The alloy is smelted by the high-frequency induction melting method protected by helium, and the metal liquid is fully stirred during the smelting process. After completion, the alloy is cast into a water-cooled copper mold for rapid cooling to obtain a cast alloy ingot.

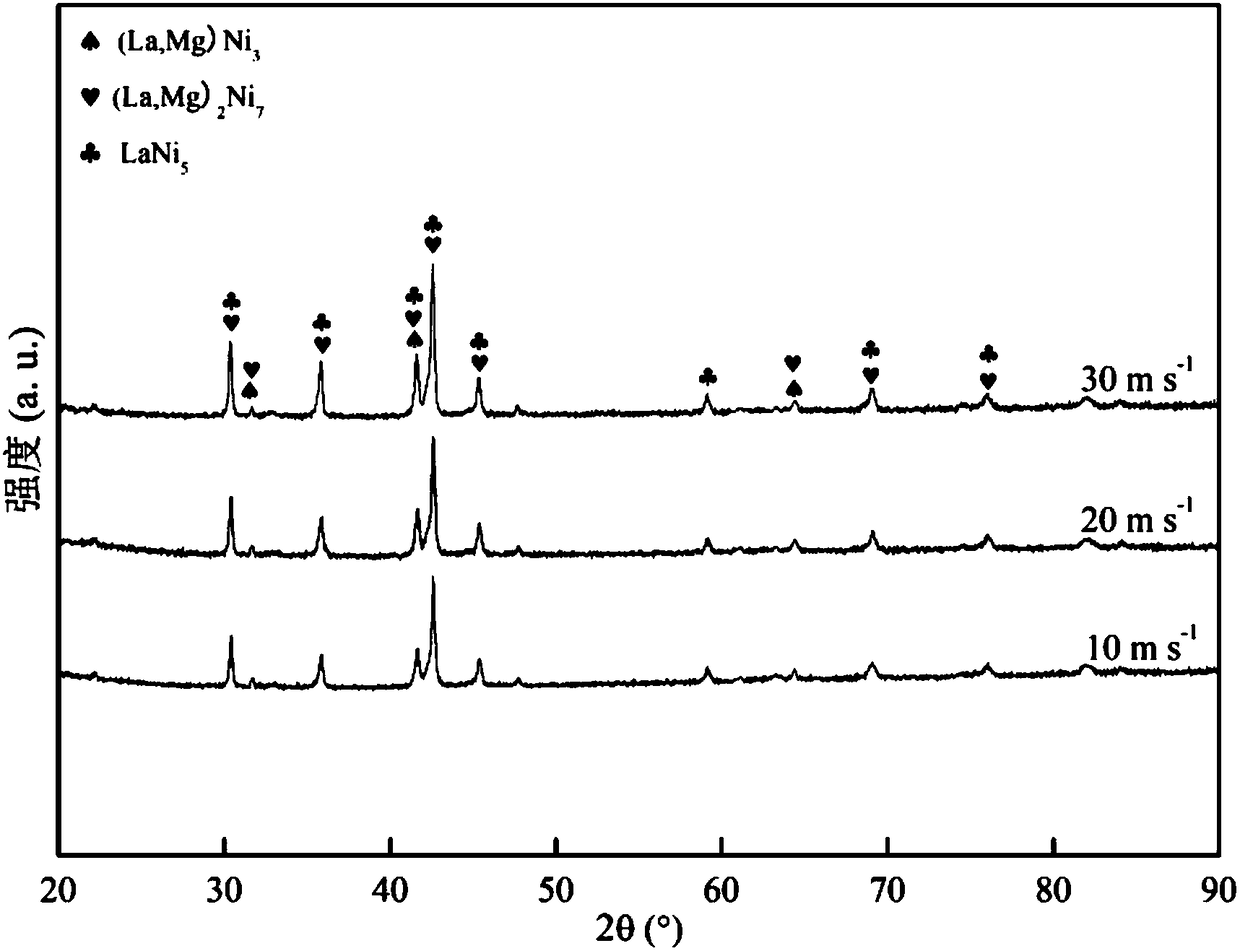

[0039] (3) The as-cast alloy ingot is placed in a single-roller quick quenching furnace, and vacuumized to 10 -2 -10 -3 Mpa is filled with 0.3MPa high-purity argon gas, and the ingot is melted by induction heating with a high-frequency power supply, and...

Embodiment 2

[0074] La 0.65 Ce 0.1 Mg 0.25 Ni 3 co 0.5 Preparation of alloy powders, including:

[0075] (1) According to La 0.65 Ce 0.1 Mg 0.25 Ni 3 co 0.5 The atomic ratio of the components is weighed and put into the alumina crucible;

[0076] (2) The alloy is smelted by the high-frequency induction melting method protected by helium, and the metal liquid is fully stirred during the smelting process. After completion, the alloy is cast into a water-cooled copper mold for rapid cooling to obtain a cast alloy ingot.

[0077] (3) The as-cast alloy ingot is placed in a single-roller quick quenching furnace, and vacuumized to 10 -2 -10 -3 Mpa is filled with 0.3MPa high-purity argon gas, and the ingot is melted by induction heating with a high-frequency power supply, and then sprayed on the high-speed rotating water-cooled copper roller with the surface speed of 20m / s and 30m / s at 1500°C respectively. , to obtain thin alloy strips after rapid solidification;

[0078] (4) After th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com