Magnetorheological damper with built-in magnetorheological valve for damping performance control

A magnetorheological damper, magnetorheological valve technology, applied in the direction of shock absorber, shock absorber, liquid shock absorber, etc., can solve the problem of increasing the effective damping gap, the failure of the magnetorheological damper, blocking the damping gap, etc. problems, to achieve the effect of wide dynamic adjustment range, enhanced yield stress, and increased damping length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

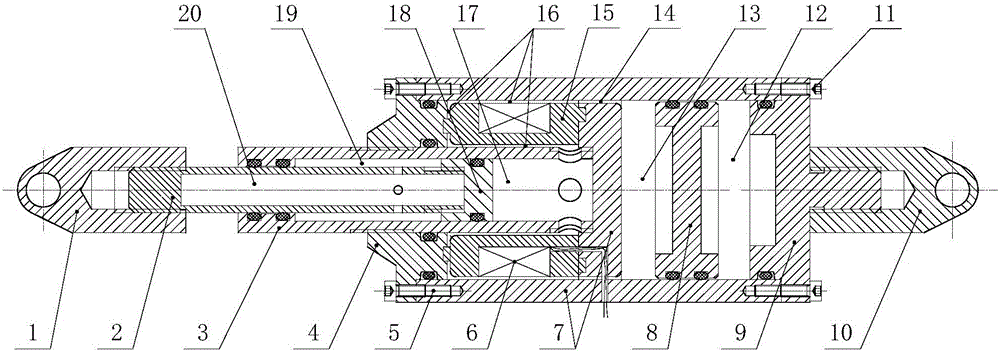

[0022] Such as figure 1 As shown, the present invention includes: left lifting lug 1, piston rod 2, piston cylinder 3, left end cover 4, screw I 5, excitation coil 6, damper cylinder 7, floating piston 8, right end cover 9, right lifting lug 10, Screw II11, compressed air chamber 12, magnetorheological fluid chamber I13, cylinder liquid flow channel 14, valve core 15, U-shaped liquid flow channel 16, magnetorheological fluid chamber II17, piston head 18, gas chamber Ⅰ19 and gas chamber Ⅱ20.

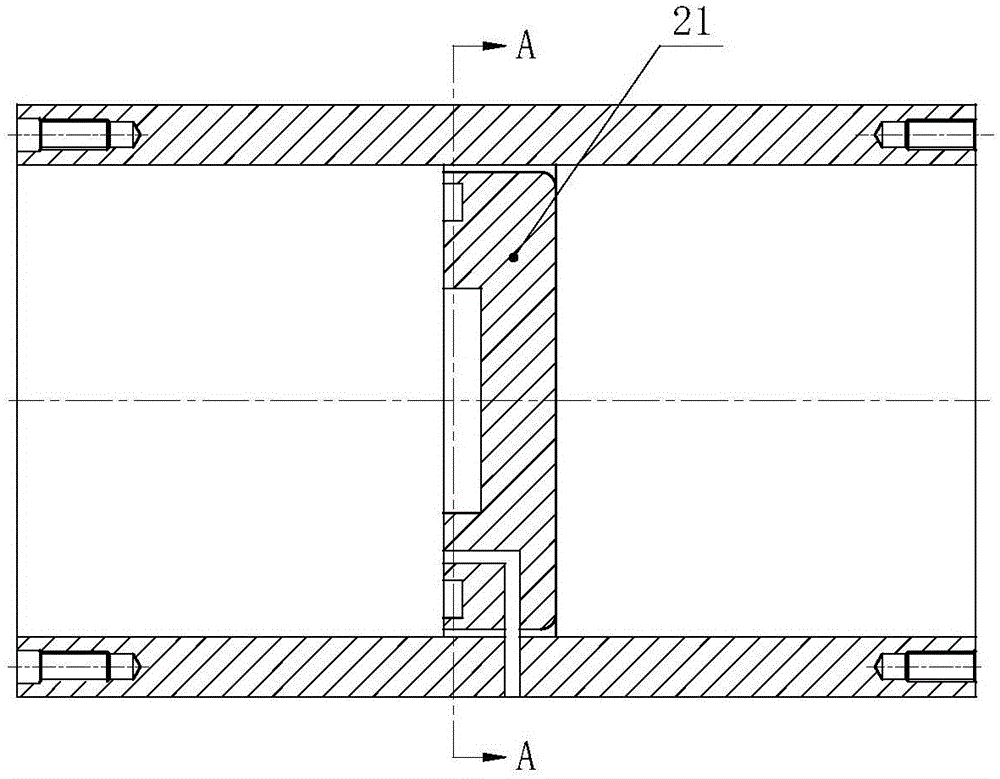

[0023] figure 2 It is a schematic diagram of the structure of the damper cylinder of the present invention, and 21 is the end cover of the damper cylinder 7 among the figures.

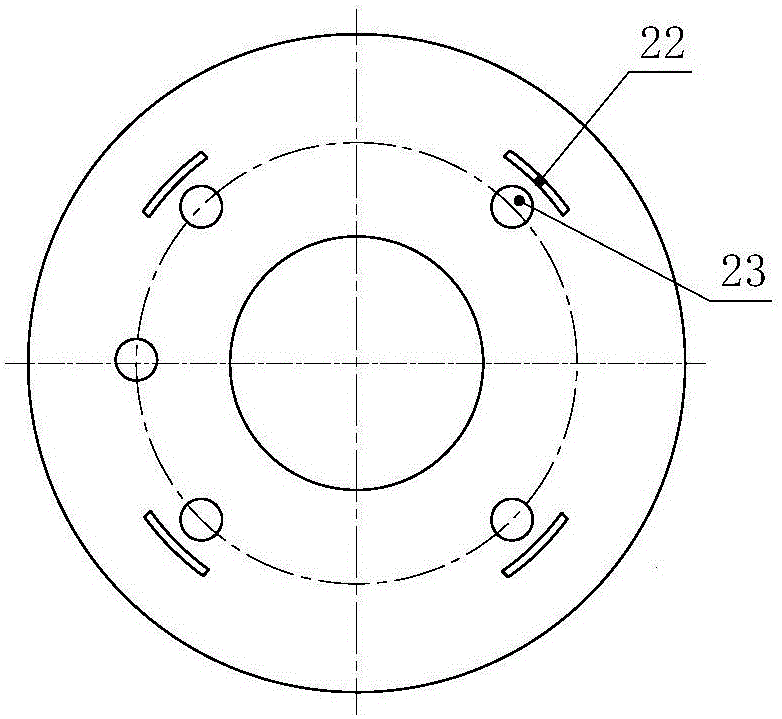

[0024] image 3 yes figure 2 The A-A sectional view of the damper cylinder block, 22 is a waist-shaped through-hole groove among the figures, and 23 is a circular groove. The end cover of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com