Method for improving fatigue performance of rare earth magnesium alloy by utilizing abnormal twin crystals

A fatigue performance and rare earth magnesium technology, which is applied in the field of improving the fatigue performance of rare earth magnesium alloys, can solve the problems of increased production costs, heavier rare earth elements, and increased alloy density, and achieve low environmental protection costs, wide range of applicable materials, and improved fatigue performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

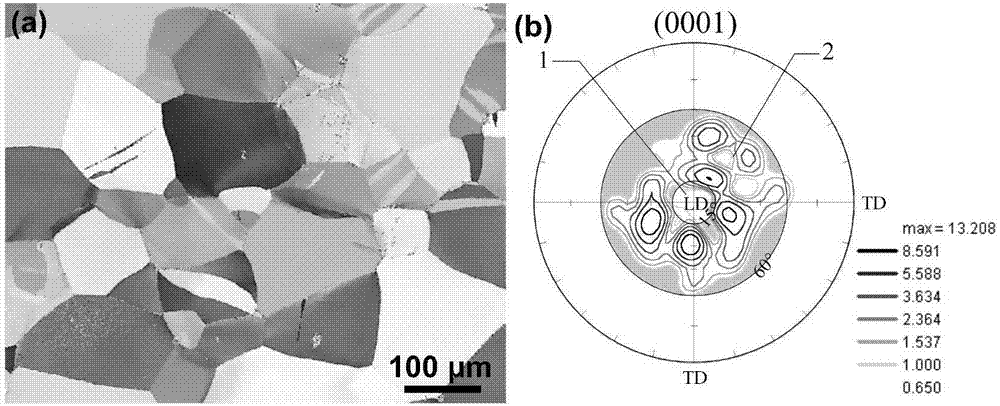

[0025] In this embodiment, the raw material is a Mg-1.5Gd alloy hot-rolled plate. After homogenizing annealing at 430℃ for 5h, the average grain size is about 120μm. The grain orientation is analyzed based on the electron backscattered diffraction technique, and the loading direction is selected according to the orientation distribution result. At 300°C, the specimen was pre-stretched along the direction of the angle 15-60° with the normal direction of the base surface, and the compression rate was 0.003s -1 , The strain is about 0.005-0.05.

[0026] The orientation distribution of the specimen after stretching is as follows: figure 1 As shown in (a), according to the criterion of abnormal twinning, the (0001) basal pole figure containing the twinned grain matrix is drawn and its area is divided, where LD (Loading Direction) is the pre-deformed loading stress direction ( perpendicular to the direction of the paper), TD (Transverse Direction) is the transverse direction at...

Embodiment 2

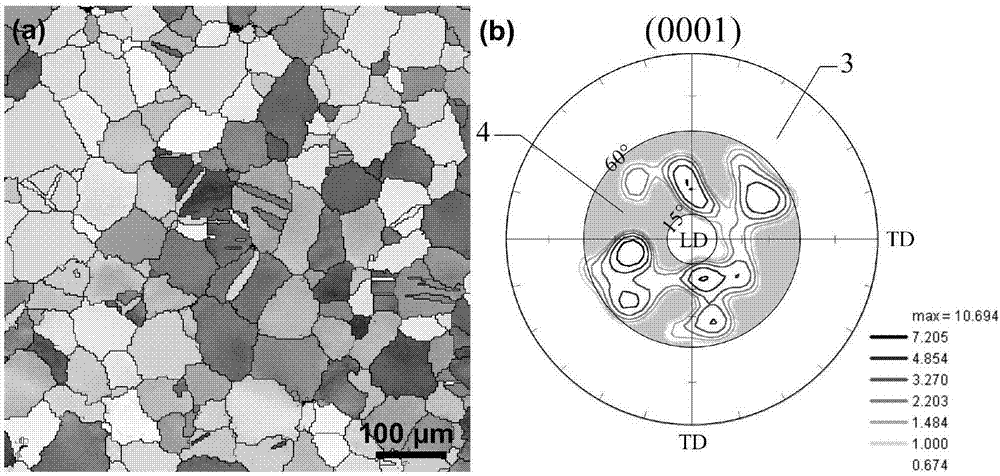

[0029] The raw material used in this embodiment is the cast Mg-6Gd-3Y-1Zn-0.4Zr alloy. The average grain size is about 60 μm. At 25°C, 0.03s -1 Next, the specimen is pre-compressed along the angle 15-60° with the normal direction of the base surface, and the strain amount is about 0.01-0.03.

[0030] Based on the electron backscattered diffraction technique, the grain orientation of the stretched specimen was analyzed, and the orientation distribution was obtained image 3 (a), the (0001) basal pole figure containing the twinned grain matrix is drawn and its area is divided. After compression along the LD direction (perpendicular to the paper surface) and pre-deformation treatment, 3 is the normal twinning area, 4 is the abnormal twin region, such as image 3 (b) shown. From image 3 (b) It can be seen that the angle between the loading direction and the normal direction of the (0001) basal plane of these grains is mainly concentrated at 15-60°, which meets the abnormal...

Embodiment 3

[0033] In this embodiment, the raw material is Mg-2Y magnesium alloy hot-rolled sheet, and after homogenizing annealing at 450° C. for 2 hours, the average grain size is about 120 μm. It was subjected to pre-bending treatment at 150°C. Due to the particularity of repeated bending deformation, the tissues on both sides of the neutral layer will be subjected to loads in two opposite directions during repeated bending. A suitable bending method should be selected to ensure that the grain basal plane is 15-60° to the loading direction, and the cumulative strain is about 0.002-0.04.

[0034] Orientation distribution of tissue after pre-deformation Figure 5 (a) Analysis and the (0001) basal pole figure containing twin grains Figure 5 (b) make and divide areas, Figure 5 In (b), 5 is the normal twinning region corresponding to stretching or compression along the LD direction (perpendicular to the paper surface) during repeated bending, and 6 is the abnormal twinning region. Dep...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average grain size | aaaaa | aaaaa |

| Average grain size | aaaaa | aaaaa |

| Fatigue limit | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com