Giant magnetostrictive material-driven intelligent boring rod

A technology of giant magnetostrictive and giant magnetostrictive rods, which is applied in the field of boring bars for boring machines, can solve the problems of difficult power supply and high-speed boring, and achieve the effects of large driving force, fast response speed, and high controllable precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

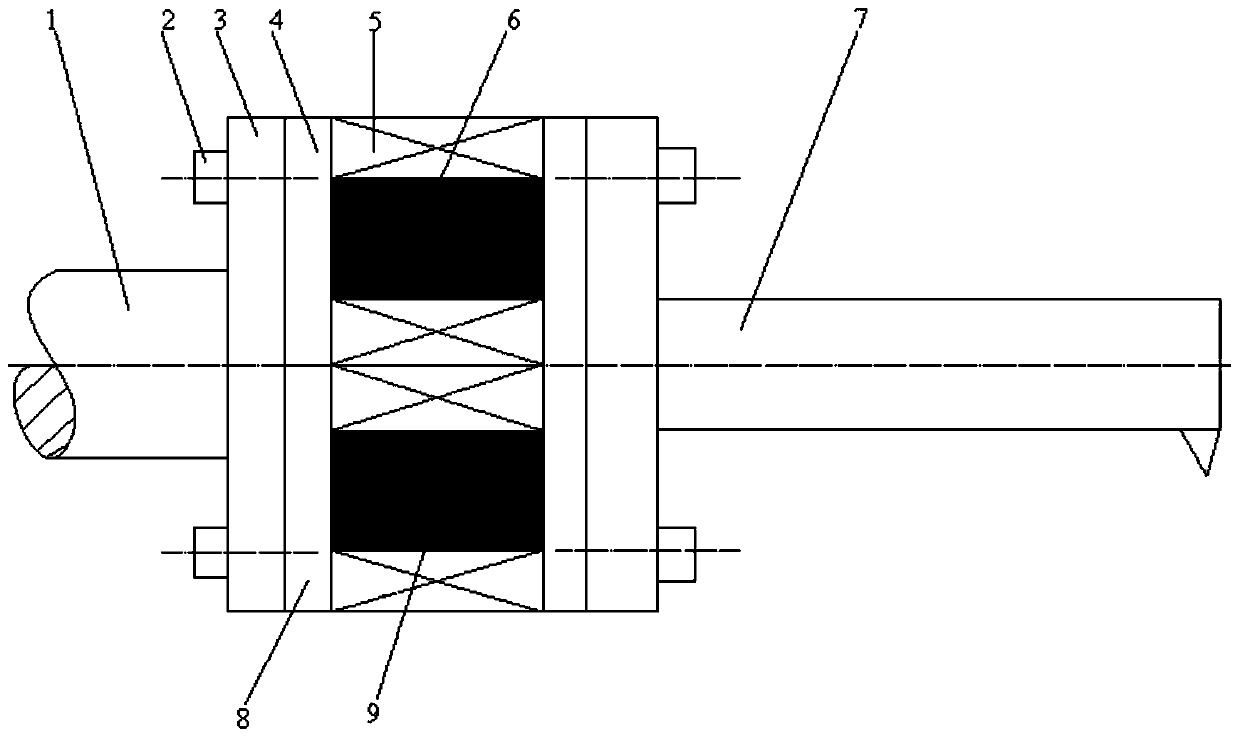

[0013] see figure 1 , an intelligent boring bar driven by giant magnetostrictive materials, comprising a static pressure boring machine main shaft 1, a fixing seat 3 is fixedly installed on the static pressure boring machine main shaft 1, and upper and lower excitation coil brackets 4 are respectively fixedly installed on the fixing seat 3 , 8, upper and lower excitation coil supports 4,8 are respectively fixedly installed with upper and lower giant magnetostrictive rods 6,9, upper and lower excitation coil supports 4,8 are respectively fixed on upper and lower giant magnetostrictive rods 6 The exterior of , 9 is correspondingly wound with an excitation coil 5 , a boring bar 7 is fixedly connected between the upper and lower giant magnetostrictive rods 6 , 9 , and a cutter is fixedly connected to the front end of the boring bar 7 .

[0014] In the present invention, screw holes are respectively provided on the upper and lower excitation coil supports 4, 8, and through holes co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com