Ge-As-Se infrared glass with anti-reflection film and preparation method thereof

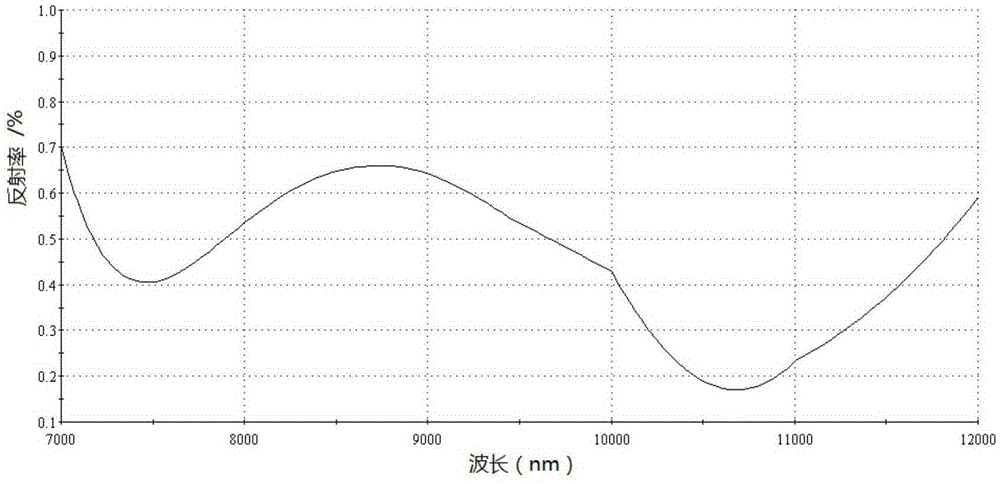

A technology of infrared glass and anti-reflection film, which is applied in the direction of optical components, optics, instruments, etc., can solve the problems of film layer shedding, poor physical and chemical properties, and more film materials, so as to reduce residual reflectivity, good stress matching, and improve transparency. over performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] The preparation method of the germanium antimony selenium infrared glass with antireflection coating comprises the following steps:

[0038] (1) Cleaning and preheating: ultrasonically clean the infrared glass substrate with a mixture of acetone and alcohol ether, the cleaning time is 15 minutes each, and finally, put the substrate in an oven for drying; after drying, quickly clamp the substrate Place in a vacuum chamber and draw a vacuum. Vacuum up to 5.0×10 -3 pa, adjust the output voltage of the baking lamp, the heating rate is: room temperature -60°C, 30min, 60°C-100°C, 30min, after reaching the temperature, keep warm for 1.2h.

[0039] What needs to be explained here is that germanium antimony selenium infrared glass is a brittle material, and gradient heating can prevent glass breakage caused by drastic temperature changes.

[0040] (2) Ion-assisted cleaning, turn on the ion source, fill the volume of argon gas with 35 sccm, and the pressure of the vacuum chambe...

Embodiment 2

[0053] 分别采用丙酮和酒精乙醚混和液对红外玻璃基底进行超声波清洗,清洗时间分别为各13min和16min,最后,将基底放入烘箱烘干。

[0054] 烘干完成后,快速装夹基底放入真空室,抽取真空;真空达到8.0×10 -3 pa,调整烘烤灯输出电压,升温速率为:室温-60℃,30min,60℃-120℃,40min;到温后,保温1.5小时。

[0055] 充入氩气40sccm,真空室压强为8.0×10 -3 pa,开启离子源,调整离子源参数为:阳极电压100V,阳极电流为2A,工件盘转速为10rpm。

[0056] Plating the first YbF 3 膜,蒸镀时真空室压强为1.0×10 -2 pa,沉积速率为0.15nm / s,采用晶振仪控制沉积速率,沉积光学厚度为153nm,采用光学膜厚仪控制膜层光学厚度。

[0057] 镀制第一ZnS膜,蒸镀时真空室压强为9.0×10 -3 pa,沉积速率为1.5nm / s,沉积光学厚度为1697nm,采用晶振仪控制沉积速率,采用光学膜厚仪控制膜层光学厚度。

[0058] Plating a second YbF 3 膜,蒸镀时真空室压强为1.0× -2 pa,沉积速率为0.15nm / s,沉积光学厚度为1646nm,采用晶振仪控制沉积速率,采用光学膜厚仪控制膜层光学厚度。

[0059] 镀制第二ZnS膜,蒸镀时真空室压强为9.0×10 -3 pa,沉积速率为1.5nm / s,沉积光学厚度为358nm,采用晶振仪控制沉积速率,采用光学膜厚仪控制膜层光学厚度。

[0060] 镀制完成后,按以下降温速率降温:120℃-60℃,55min,60℃-室温,25min,取出镀膜红外玻璃。

[0061] 这里需要说明的是:本实施例利用硫化锌与氟化镱应力类型相反,并控制单层和总厚度大小,实现了良好的应力匹配。

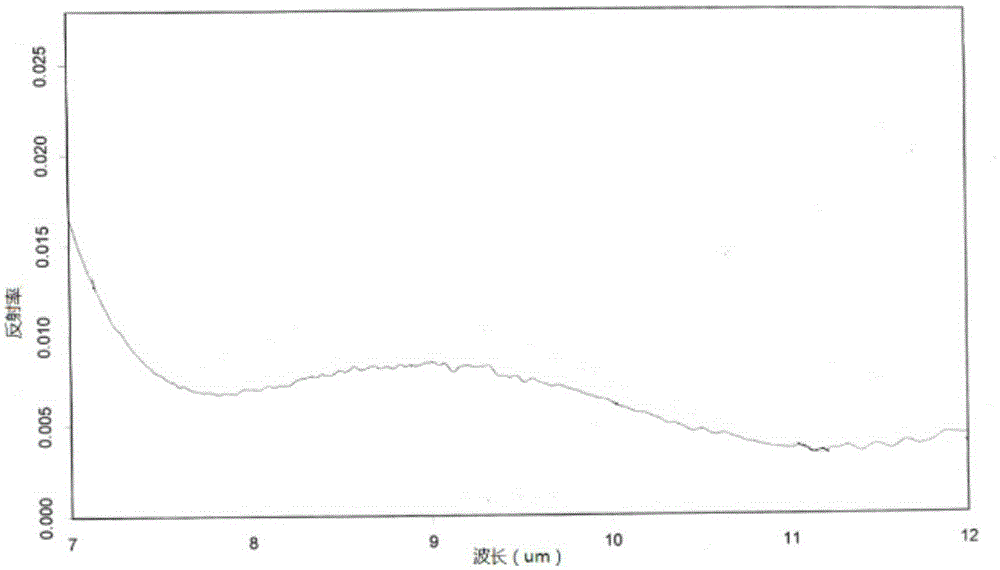

[0062] 膜层与基底,膜层与膜层间附着力良好;剩余反射率低,满足光学系统对红外玻璃的透过要求;镀膜时采用梯度升温和降温,有效避免了红外玻璃因温度变化大导致的易破裂等问题;采用低能高密度离子辅助沉积方式,避免了镀膜过程中的温升,提高了膜层的性能。

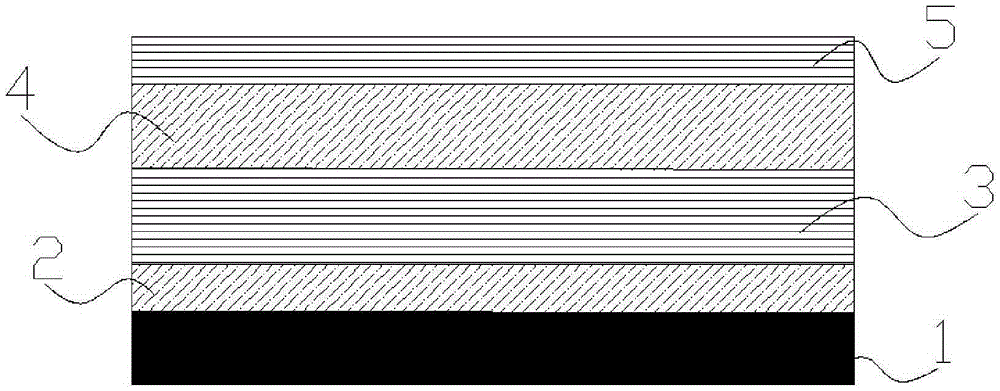

[0063] 本实施制备的具有的膜系结构为2种膜料组成的4层结构;第1层为YbF 3 ,光学厚...

Embodiment 3

[0065] 分别采用丙酮和酒精乙醚混和液对红外玻璃基底进行超声波清洗,清洗时间分别为各18min和12min,最后,将基底放入烘箱烘干。

[0066] 烘干完成后,快速装夹基底放入真空室,抽取真空;真空达到1.0×10 -2 pa,调整烘烤灯输出电压,升温速率为:室温-60℃,30min,60℃-120℃,40min;到温后,保温1.5小时。

[0067] 充入氩气40sccm,真空室压强为2.0×10 -2 pa,开启离子源,调整离子源参数为:阳极电压150V,阳极电流为1A,工件盘转速为20rpm。

[0068] Plating the first YbF 3 膜,蒸镀时真空室压强为2.0×10 -2 pa,沉积速率为0.15nm / s,采用晶振仪控制沉积速率,沉积光学厚度为193nm,采用光学膜厚仪控制膜层光学厚度。

[0069] 镀制第一ZnS膜,蒸镀时真空室压强为2.0×10 -2 pa,沉积速率为3nm / s,沉积光学厚度为1937nm,采用晶振仪控制沉积速率,采用光学膜厚仪控制膜层光学厚度。

[0070] Plating a second YbF 3 膜,蒸镀时真空室压强为2.0× -2 pa,沉积速率为0.3nm / s,沉积光学厚度为1486nm,采用晶振仪控制沉积速率,采用光学膜厚仪控制膜层光学厚度。

[0071] 镀制第二ZnS膜,蒸镀时真空室压强为2.0×10 -2 pa,沉积速率为3nm / s,沉积光学厚度为308nm,采用晶振仪控制沉积速率,采用光学膜厚仪控制膜层光学厚度。

[0072] 镀制完成后,按以下降温速率降温:120℃-60℃,55min,60℃-室温,25min,取出镀膜红外玻璃。

[0073] 膜层与基底,膜层与膜层间附着力良好;剩余反射率低,满足光学系统对红外玻璃的透过要求;镀膜时采用梯度升温和降温,有效避免了红外玻璃因温度变化大导致的易破裂等问题;采用低能高密度离子辅助沉积方式,避免了镀膜过程中的温升,提高了膜层的性能。

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Optical thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com