Preparation method of carbon nanotube-alumina composite reinforced magnesium-based composite material

A technology of carbon nanotubes and composite reinforcement, which is applied in the field of magnesium-based alloys manufactured by casting, can solve the problems of limited application range of composite materials, obvious dislocation strengthening effect, and poor performance control ability, so as to avoid the occurrence of tissue defects and adjust The effect of wide range and comprehensive performance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

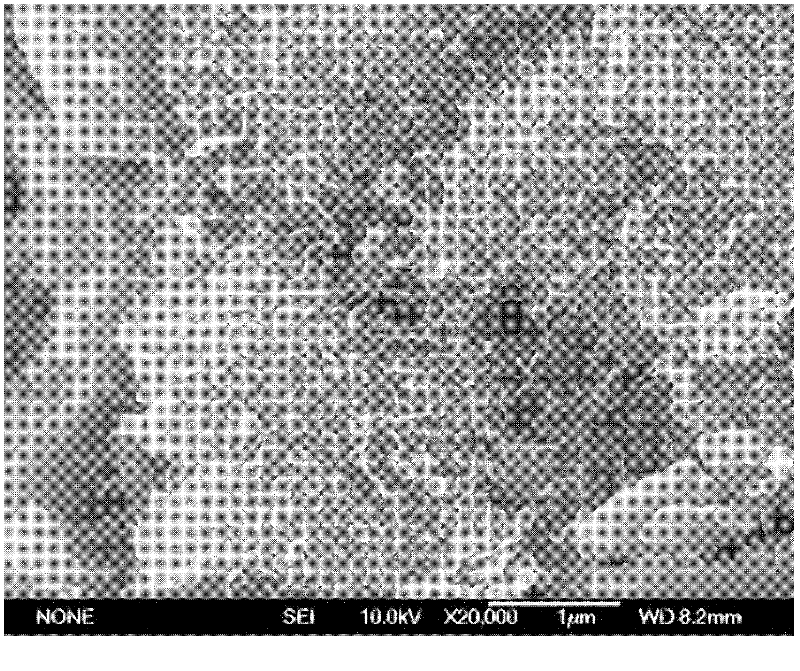

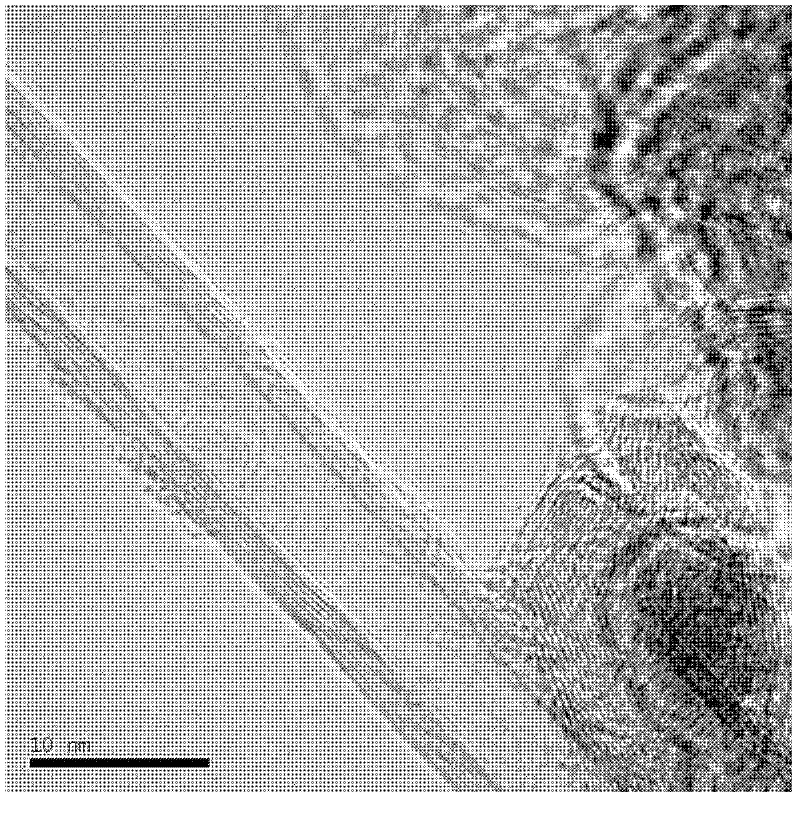

[0031] The first step, preparation of carbon nanotube-alumina composite reinforcement phase

[0032]According to the ratio of ferric nitrate nonahydrate: aluminum oxide=0.07:1 by mass ratio, the required amount of ferric nitrate nonahydrate and 200 mesh alumina particles are weighed and added to deionized water to prepare a molar concentration of 0.01mol / L ferric nitrate aqueous solution with alumina particles in it, put the system in a container and then put it into an electric constant temperature drying oven at 60°C to dehydrate until viscous, put the viscous into a quartz boat, Then place the quartz boat in the constant temperature zone of the tube furnace, and feed nitrogen into the tube furnace at a flow rate of 60ml / min, then raise the temperature of the tube furnace to 400°C and calcinate for 0.5h to obtain the calcined product iron oxide / alumina, then close the nitrogen, feed hydrogen into the tube furnace at a flow rate of 60ml / min and keep it for 0.5h, reduce the c...

Embodiment 2

[0036] Except that the magnesium alloy substrate was used instead of the pure magnesium substrate, other steps and processes were the same as in Example 1, thereby preparing the same carbon nanotube-alumina composite reinforced magnesium matrix composite material.

Embodiment 3

[0038] The first step, preparation of carbon nanotube-alumina composite reinforcement phase

[0039] According to the mass ratio of ferric nitrate nonahydrate: aluminum oxide=0.50:1, weigh the required amount of ferric nitrate nonahydrate and 300 mesh alumina particles and add it to deionized water to prepare a molar concentration of 0.05mol / L ferric nitrate aqueous solution with alumina particles in it, put the system in a container and then put it into an electric heating constant temperature drying oven at 75 ℃ to dehydrate until viscous, put the viscous into a quartz boat, Then place the quartz boat in the constant temperature zone of the tube furnace, and feed nitrogen into the tube furnace at a flow rate of 90ml / min, then raise the temperature of the tube furnace to 450°C and calcinate for 1h to obtain the calcined product iron oxide / Aluminum oxide, then close the nitrogen, feed hydrogen into the tube furnace at a flow rate of 90ml / min and keep it for 1h, reduce the cal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com