Preparation method of silicon dioxide composite material for negative electrode of lithium-ion battery

A lithium-ion battery and silicon dioxide technology, applied in battery electrodes, secondary batteries, electrochemical generators, etc., can solve problems such as poor cycle performance, difficult industrial production, and complicated preparation processes, and achieve a large expansion coefficient, Large specific surface area, the effect of reducing side reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

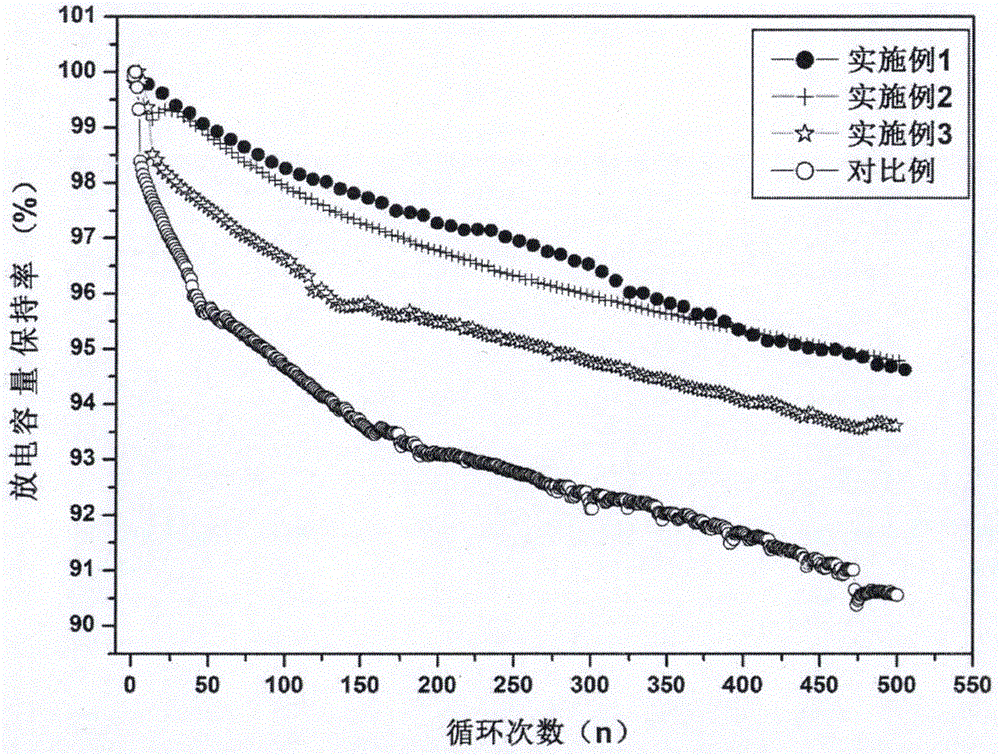

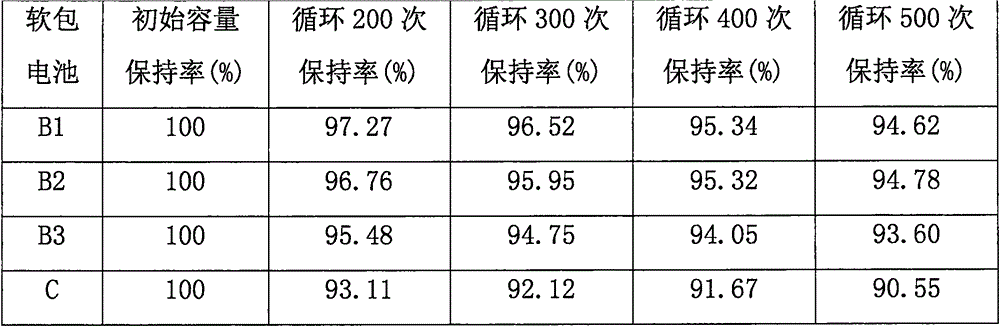

Embodiment 1

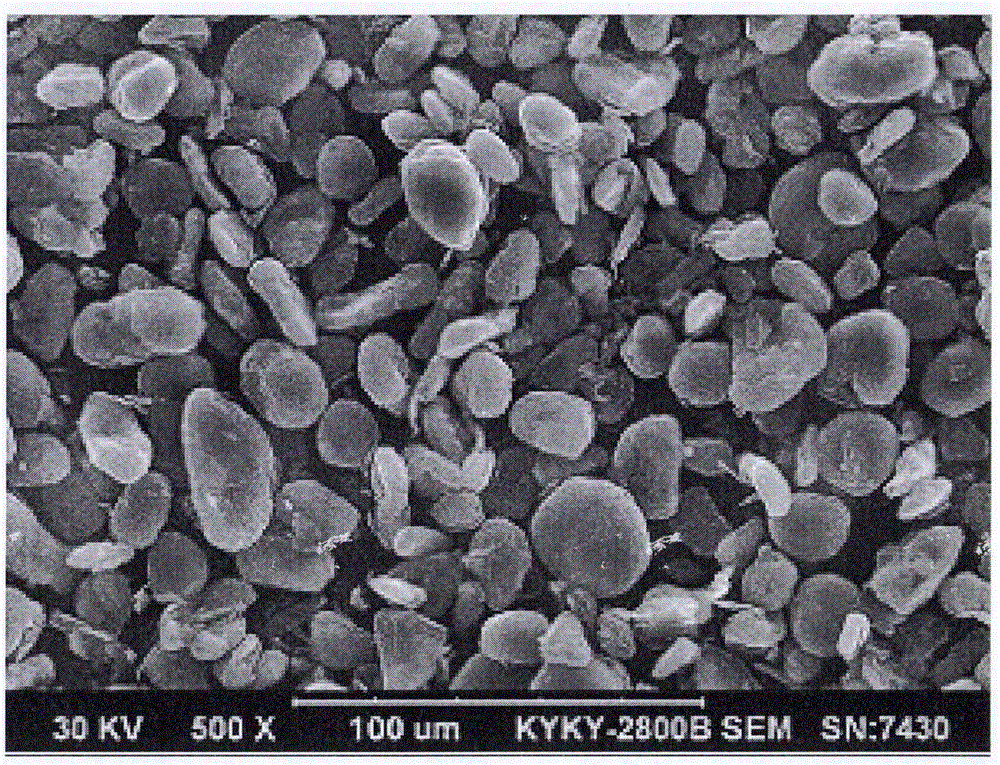

[0025] I. Preparation of [carbon nanotube / silica] composite material: Add 120mL ethanol, 40mL distilled water, 1.5mL ammonia water and 0.2mL cetyltrimethylammonium bromide to the reaction vessel and stir evenly to make it fully Dissolve, then add 0.15g acid-treated carbon nanotubes to the reaction vessel and ultrasonically disperse for 40min, after the acid-treated carbon nanotubes are completely dispersed, slowly add 1.0g orthosilicate ethyl ester dropwise to the reaction vessel and Stir at room temperature for 8 hours, then centrifuge and wash the reaction products in the reaction vessel with deionized water and absolute ethanol, and finally dry at 80°C to prepare the [carbon nanotube / silicon dioxide] composite material .

[0026] II. Preparation of silica precursor: put 100g of the [carbon nanotube / silica] composite material prepared in the above I into the reactor and add 50g of asphalt. The speed of the reactor is controlled at 500r / min, and the reaction The fusion tempe...

Embodiment 2

[0029] I. Preparation of [carbon nanotube / silica] composite material: Add 100mL ethanol, 20mL distilled water, 1.0mL ammonia water and 0.1mL cetyltrimethylammonium bromide to the reaction vessel and stir evenly to make it fully Dissolve, then add 0.1g acid-treated carbon nanotubes to the reaction dish and ultrasonically disperse for 40min,

[0030] After the acid-treated carbon nanotubes were completely dispersed, slowly drop 1.0 g of tetraethyl orthosilicate into the reaction vessel and stir for 4 hours at room temperature, and then the reaction products in the reaction vessel were successively washed with deionized water and absolute ethanol respectively. The [carbon nanotube / silicon dioxide] composite material can be prepared by performing centrifugal cleaning and finally drying at 80°C.

[0031] II. Preparation of silica precursor: put 100g of the [carbon nanotube / silica] composite material prepared in the above I into the reactor and add 30g of asphalt. The speed of the r...

Embodiment 3

[0034] I. Preparation of [carbon nanotube / silica] composite material: Add 150mL ethanol, 50mL distilled water, 2.0mL ammonia water and 0.2mL cetyltrimethylammonium bromide to the reaction vessel and stir evenly to make it fully Dissolve, then add 0.2g acid-treated carbon nanotubes to the reaction vessel and ultrasonically disperse for 40min, after the acid-treated carbon nanotubes are completely dispersed, slowly add 1.0g tetraethyl orthosilicate in the reaction vessel and Stir at room temperature for 12 hours, then centrifuge and wash the reaction products in the reaction vessel with deionized water and absolute ethanol in turn, and finally dry at 80°C to prepare the [carbon nanotube / silicon dioxide] composite material .

[0035] II. Preparation of silica precursor: put the 100g [carbon nanotube / silica] composite material prepared in the above I into the reactor and add 60g of asphalt, the speed of the reactor is controlled at 1000r / min, and the reaction The fusion temperatu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com