Thermomechanical treatment method for improving stress corrosion resistance of 7xxx series aluminum alloy

A technology of deformation heat treatment and stress corrosion, which is applied in the field of aluminum alloy and can solve problems such as strength loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to further understand the present invention, the preferred embodiments of the present invention are described below in conjunction with examples, but it should be understood that these descriptions are only to further illustrate the features and advantages of the present invention, rather than limiting the claims of the present invention.

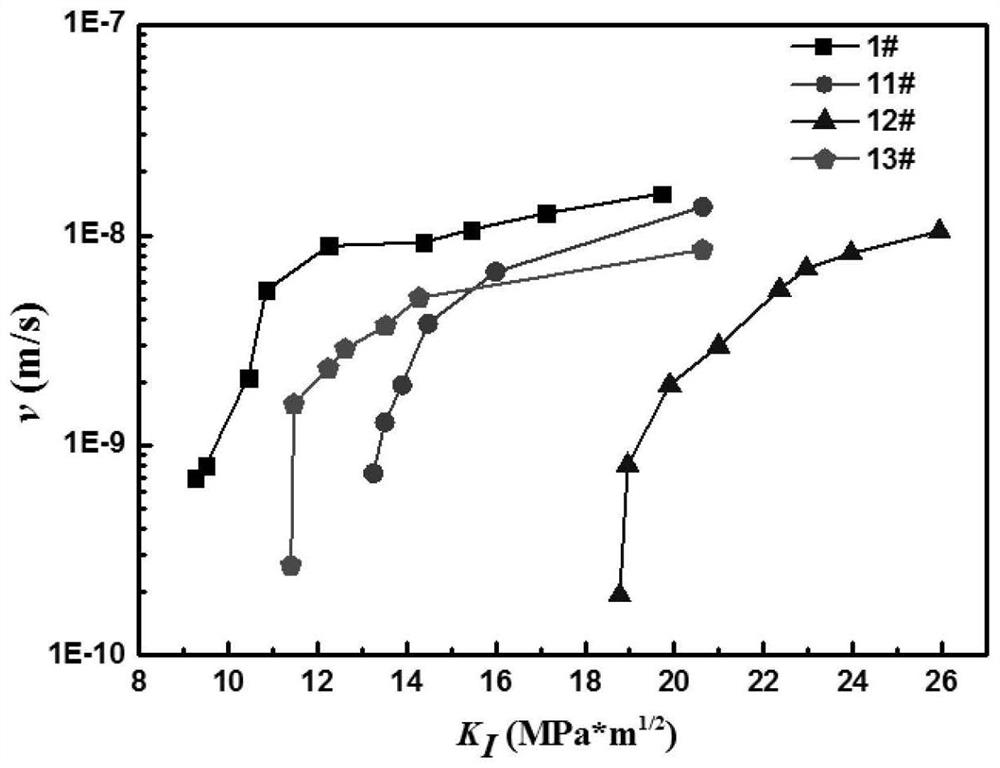

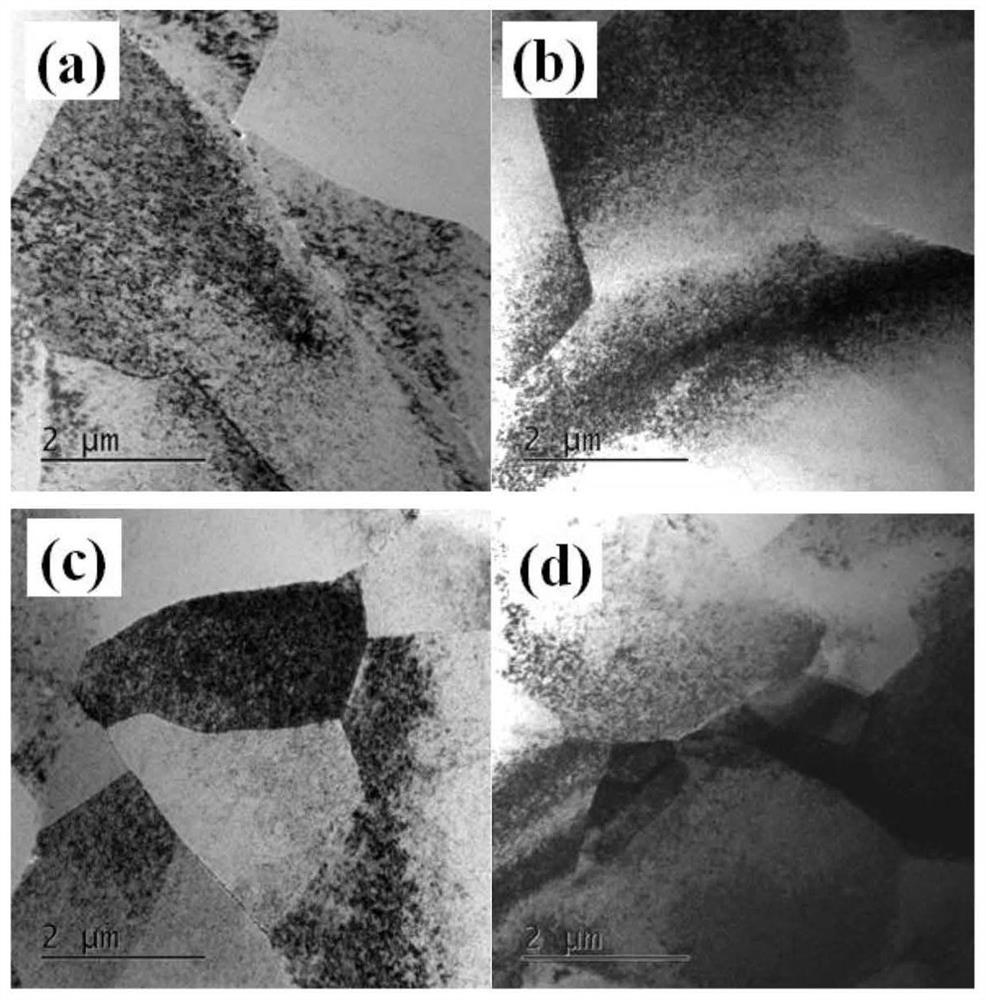

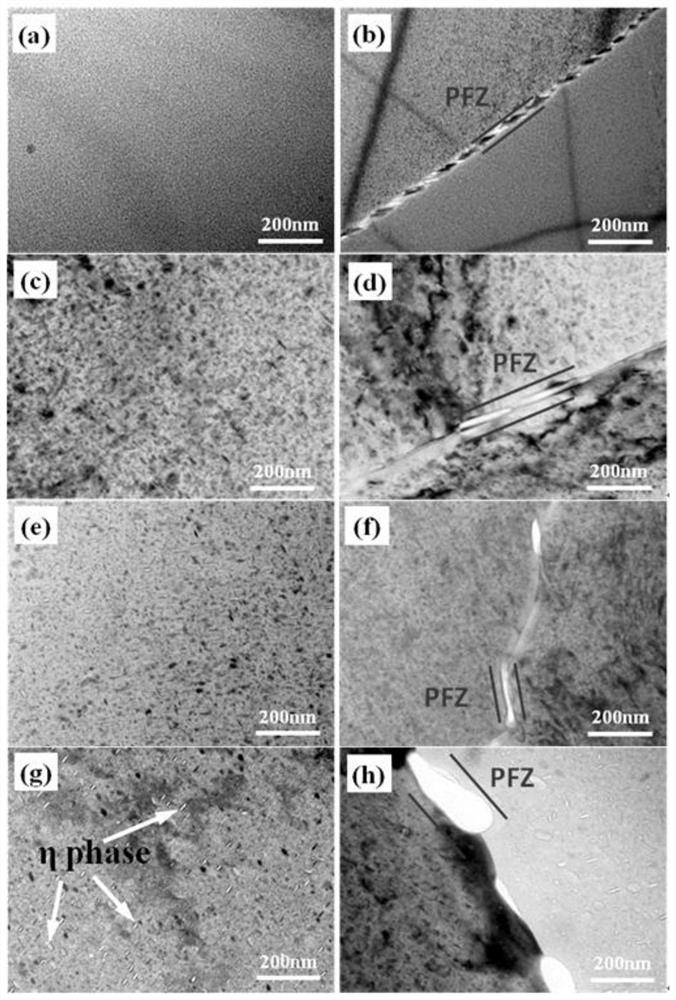

[0021] In view of the imbalance between the strength and corrosion resistance of 7xxx series aluminum alloys, this application provides a deformation heat treatment method to improve the stress corrosion resistance of 7xxx series aluminum alloys. This method only uses pre-cooling deformation and three-stage artificial aging heat treatment to achieve It achieves both high strength and good corrosion resistance of 7xxx series aluminum alloys, and overcomes the problem that the ultra-high strength and excellent corrosion resistance of 7xxx series aluminum alloys cannot be balanced. Specifically, the embodiment of the present inv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com