Negative plate and application thereof

A technology of negative electrode sheet and negative electrode activity, which is applied to the negative electrode sheet and its application field, can solve the problems of increased polarization, increased internal resistance, thermal runaway, etc. The effect of raising the nucleation barrier

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

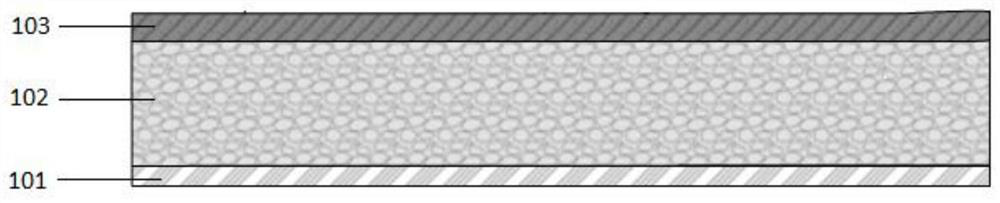

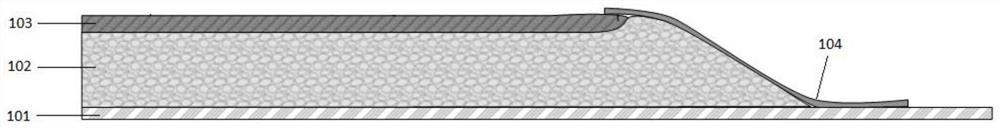

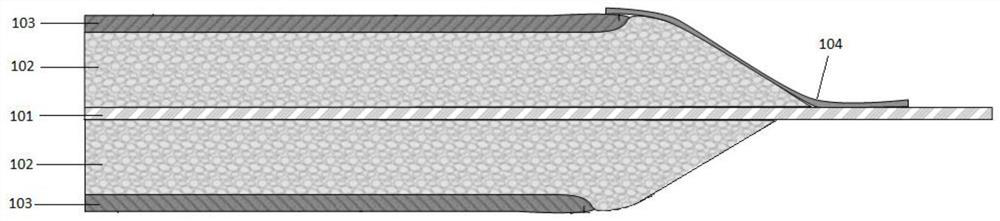

[0055] The schematic diagram of the negative plate of the present embodiment is as follows image 3 As shown, the preparation method of negative electrode sheet and lithium ion battery is as follows:

[0056] 1) Preparation of negative electrode sheet

[0057] Graphite, conductive carbon black, styrene-butadiene latex (SBR), and sodium carboxymethylcellulose (CMC) are added to deionized water at a mass ratio of 96:1.5:1.5:1 and stirred evenly to make a negative electrode active slurry; The obtained negative electrode active slurry is evenly coated on the upper and lower functional surfaces of the negative electrode current collector 101 copper foil, the pole piece width is 50 mm, and the total length of the pole piece is 942 mm. The coating length of the functional surface is 888mm, and the coating length of the lower functional surface is 776mm. The negative electrode active slurry coated on the upper and lower functional surfaces of the copper foil is aligned with one end, ...

Embodiment 2

[0066] The difference between this embodiment and Embodiment 1 is that the mass percent content of each component of the safety function layer 103 in the negative electrode sheet is 55% nickel, 35% boehmite, and 6% polyvinylidene fluoride ( PVDF), 4% polyvinylpyrrolidone (PVP). The rest of the steps are the same as in Example 1, and will not be repeated here.

Embodiment 3

[0068] The difference between this embodiment and Embodiment 1 is that the mass percentages of the components of the safety function layer 103 in the negative electrode sheet are 60% nickel, 30% boehmite, and 6% polyvinylidene fluoride ( PVDF), 4% polyvinylpyrrolidone (PVP). The rest of the steps are the same as in Example 1, and will not be repeated here.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com