Coking wastewater pretreatment method

A coking wastewater pretreatment technology, applied in water/sewage treatment, chemical instruments and methods, water/sewage multi-stage treatment, etc., can solve the problems of poor ammonia nitrogen treatment effect, compaction, channeling and other problems in the pretreatment of coking wastewater, and achieve The effect of widening the pH range, reducing the treatment cost and improving the treatment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

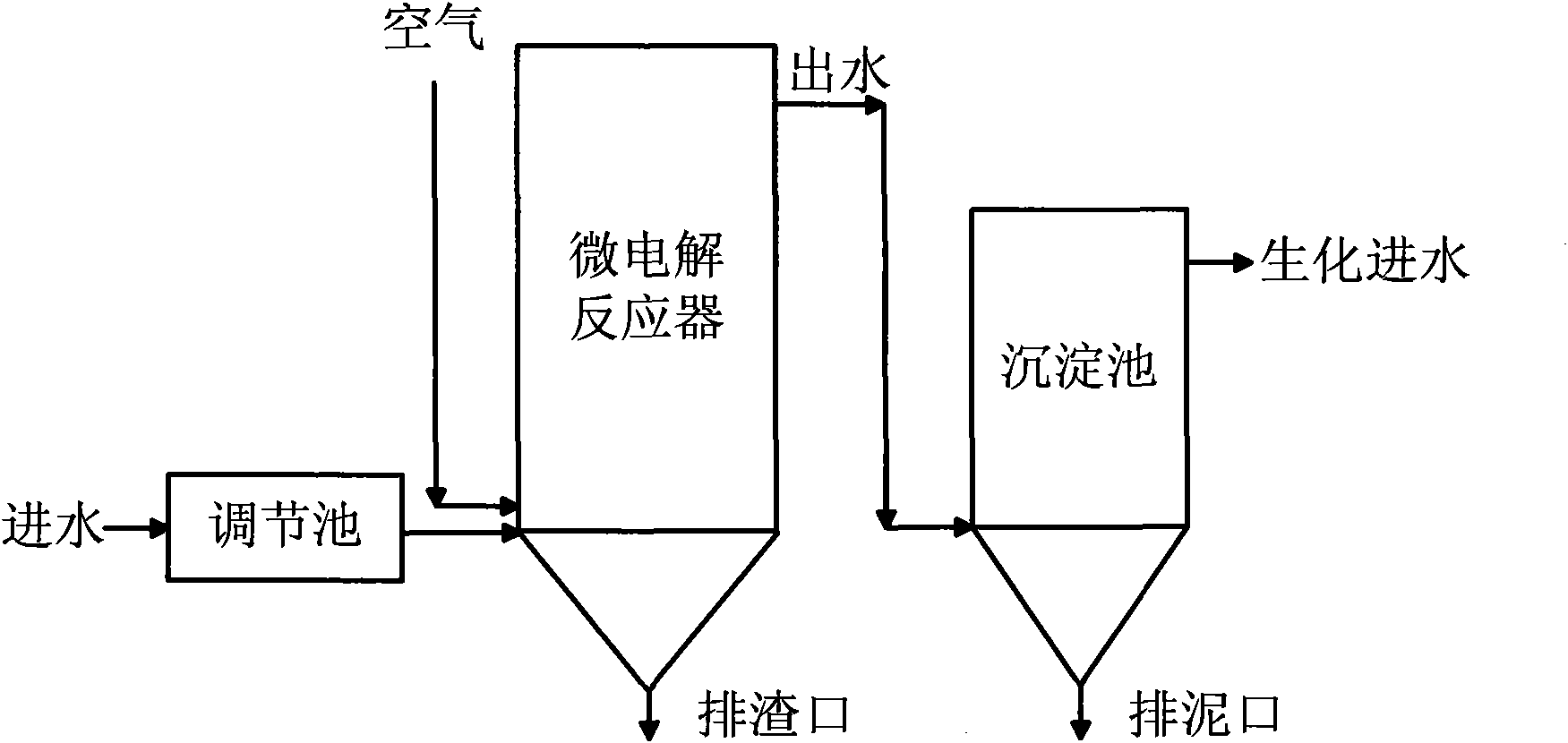

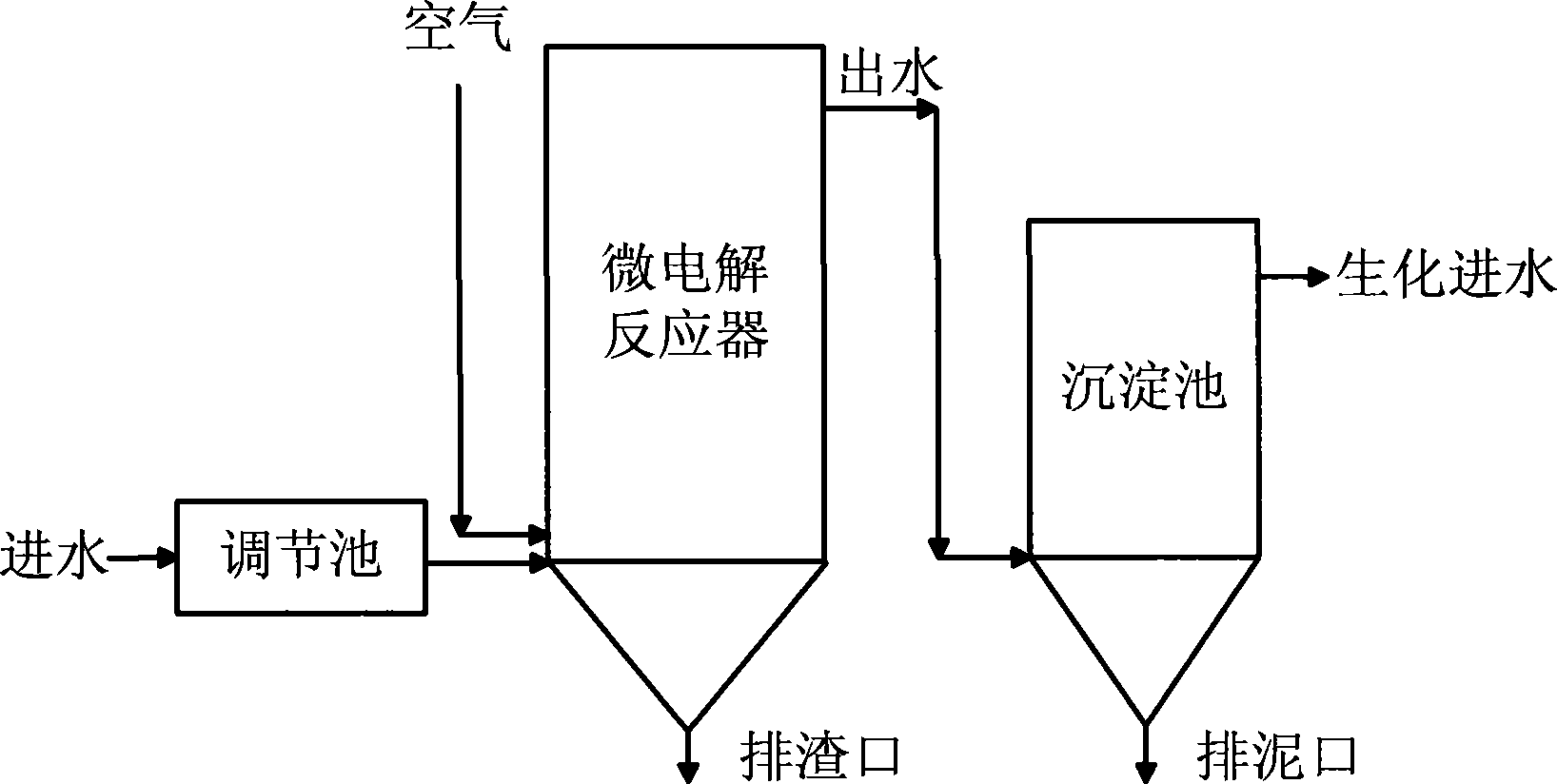

[0023] A kind of coking waste water pretreatment method of the present invention comprises the following steps: (1) coking waste water enters the adjustment pond, carries out water quality adjustment, and influent COD, ammonia nitrogen and chromaticity are respectively about 3000mg / L, 150mg / L, 600 times (2) The coking waste water that comes out from regulating pond enters micro-electrolysis reactor, reacts with the filler in the micro-electrolysis reactor, and filler is industrial waste iron shavings, scrap copper scrap and zeolite, and its mass ratio is 10: 2: 1 ; The pH of the micro-electrolysis reactor inlet water is 2.0, the hydraulic retention time is 60min, air aeration is used, and industrial waste iron shavings are replenished every 3 days; (3) The effluent of the micro-electrolysis reactor enters the sedimentation tank for flocculation and precipitation, and the effluent of the sedimentation tank is COD 1500-2000mg / L, ammonia nitrogen 90-110mg / L, and chroma 50-100 time...

Embodiment 2

[0025] A kind of coking waste water pretreatment method of the present invention comprises the following steps: (1) coking waste water enters the adjustment pond, carries out water quality adjustment, and influent COD, ammonia nitrogen and chromaticity are respectively about 4500mg / L, 60mg / L, 1000 times (2) The coking waste water that comes out from regulating tank enters micro-electrolysis reactor, reacts with the filler in the micro-electrolysis reactor, and filler is industrial waste iron shavings, waste copper scrap and zeolite, and its mass ratio is 8: 1: 0.2 ; Micro-electrolysis reactor inlet water pH = 4.0, hydraulic retention time 20min; (3) Micro-electrolysis reactor effluent enters the sedimentation tank for precipitation, and the effluent COD of the sedimentation tank is 3000-3600mg / L, ammonia nitrogen is 30-40mg / L, color The degree is 100 to 300 times.

Embodiment 3

[0027] A kind of coking waste water pretreatment method of the present invention comprises the following steps: (1) coking waste water enters the adjustment pond, carries out water quality adjustment, and influent COD, ammonia nitrogen and chromaticity are respectively about 4500mg / L, 60mg / L, 1000 times (2) The coking waste water that comes out from regulating pool enters micro-electrolysis reactor, reacts with the filler in the micro-electrolysis reactor, and filler is industrial waste iron shavings, waste copper scrap and zeolite, and its mass ratio is 12: 3: 3 ; Micro-electrolysis reactor inlet water pH=12.0, hydraulic retention time 40min; (3) Micro-electrolysis reactor effluent enters the sedimentation tank for precipitation, and the COD of the sedimentation tank effluent is 2500-3000mg / L, ammonia nitrogen is 25-35mg / L, color The degree is 100 to 150 times.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com