Manufacturing process for battery pole piece

A technology for battery pole pieces and manufacturing methods, which is applied in the direction of electrode manufacturing, battery electrodes, circuits, etc., can solve the problems of easy falling off of active materials, low cycle life, short circuit of batteries, etc., and achieve improved bonding effect, increased energy density, and reduced The effect of safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

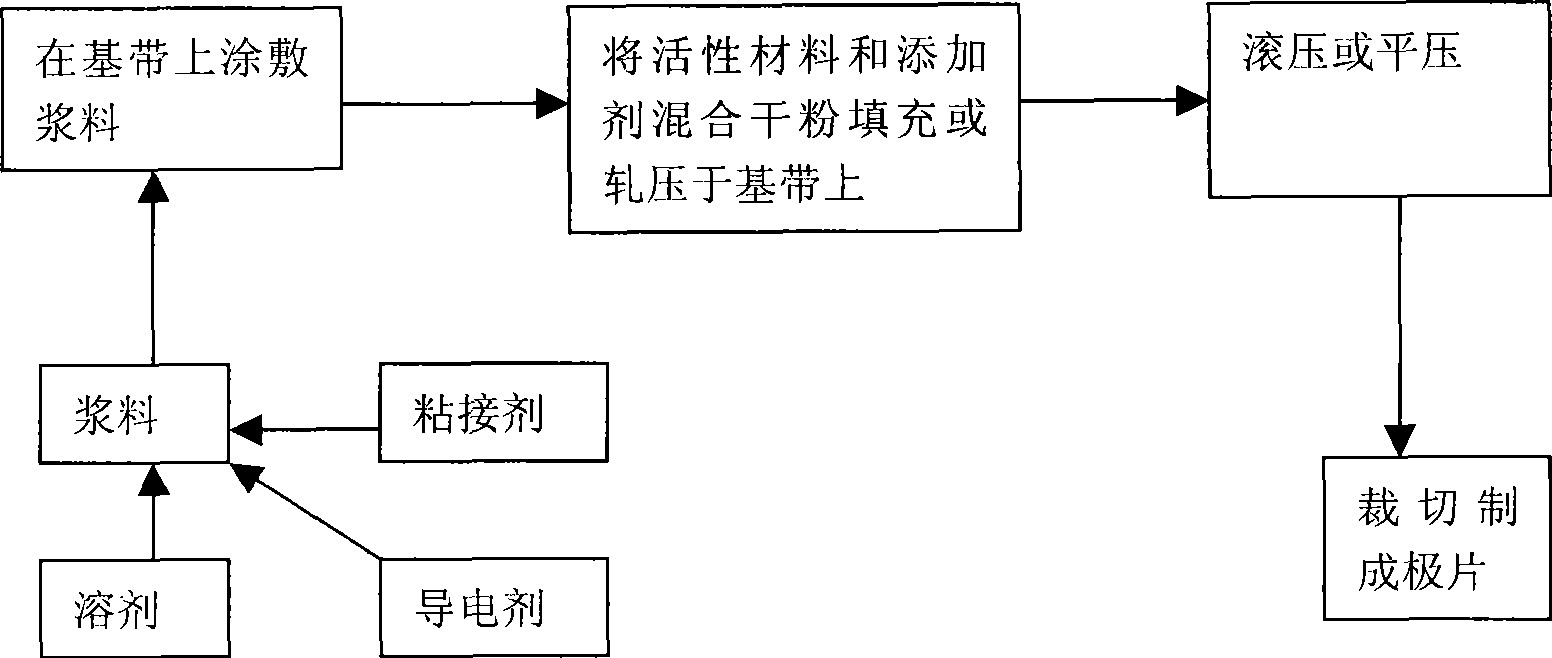

[0019] see figure 1 , First spray the slurry on the battery baseband, the slurry is composed of alcohol mixed with water and ethanol, and then sprinkle the active material and additive mixed powder on the battery baseband, then roll and cut into battery pole pieces .

Embodiment 2

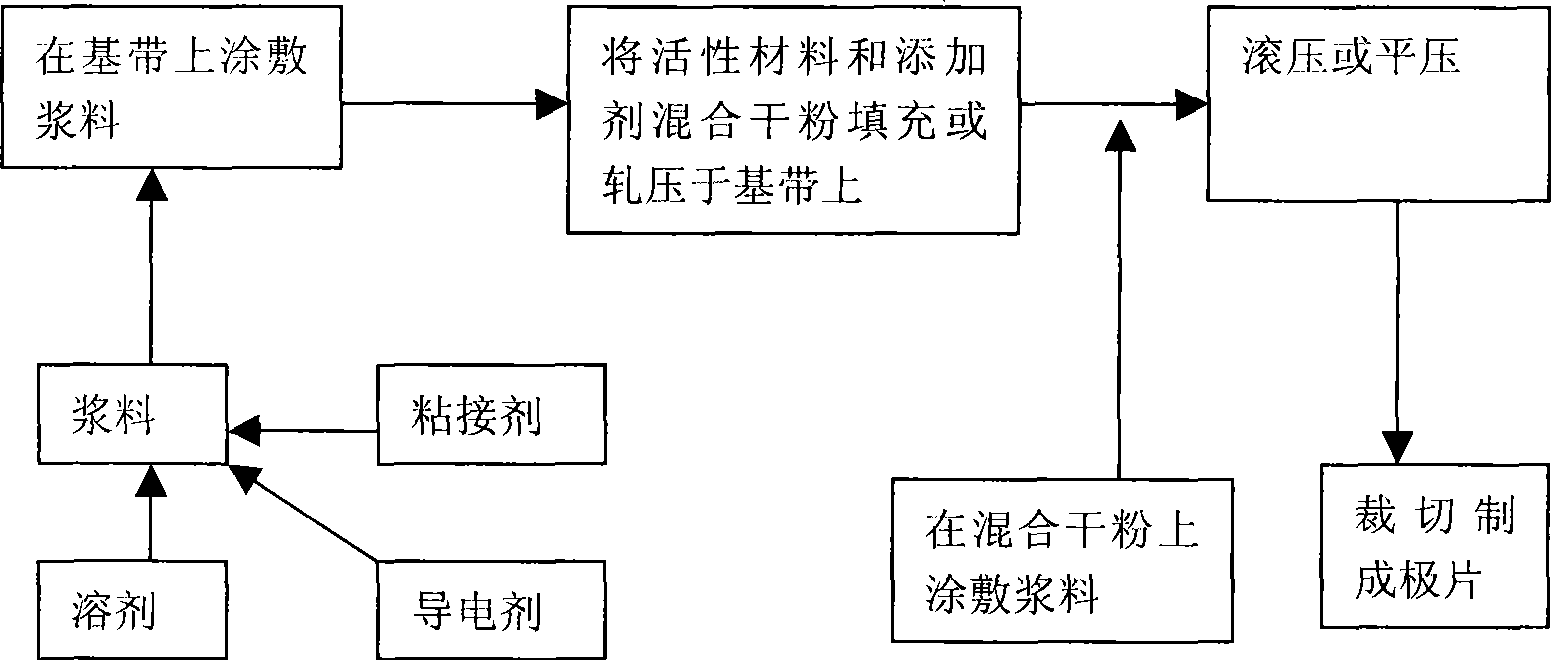

[0021] see figure 2 , first brush the slurry on the battery baseband, the slurry is mixed with 1 kg of water, 0.35 kg of PTFE as a binder, and 0.05 kg of nickel powder as a conductive agent (if a certain concentration of PTFE emulsion is used , the amount of water can be reduced accordingly), then brush the mixed powder of the active material and the additive into the base tape coated with the slurry, and then spray a layer of the above slurry on its surface, then flatten it, and finally cut it. , made into battery pole pieces.

Embodiment 3

[0023] like figure 2 As shown in the figure, firstly, brush the slurry on the battery base tape. The slurry is mixed with 1 kg of mixed solvent of N-methylpyrrolidone and ethanol in any proportion, polyvinyl alcohol and polyvinylidene fluoride in any proportion to form adhesive powder 0.02 kg, nickel powder and carbon powder are mixed in any proportion to form a conductive agent mixed powder of 0.1 kg, and then the mixed powder of the active material and the additive is rolled and pressed on the base tape coated with the slurry, and then sprayed on its surface. Layer the above slurry, then flatten it, and finally cut it to make a battery pole piece.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com