High performance nano polyurethane micropore elastomer composite material and preparation thereof

A technology of microcellular elastomer and composite material, applied in the field of polyurethane composite materials, can solve the problems of poor mechanical properties of polyether polyurethane microcellular elastomer, and achieve the effects of stable product quality, low production cost, and improved tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

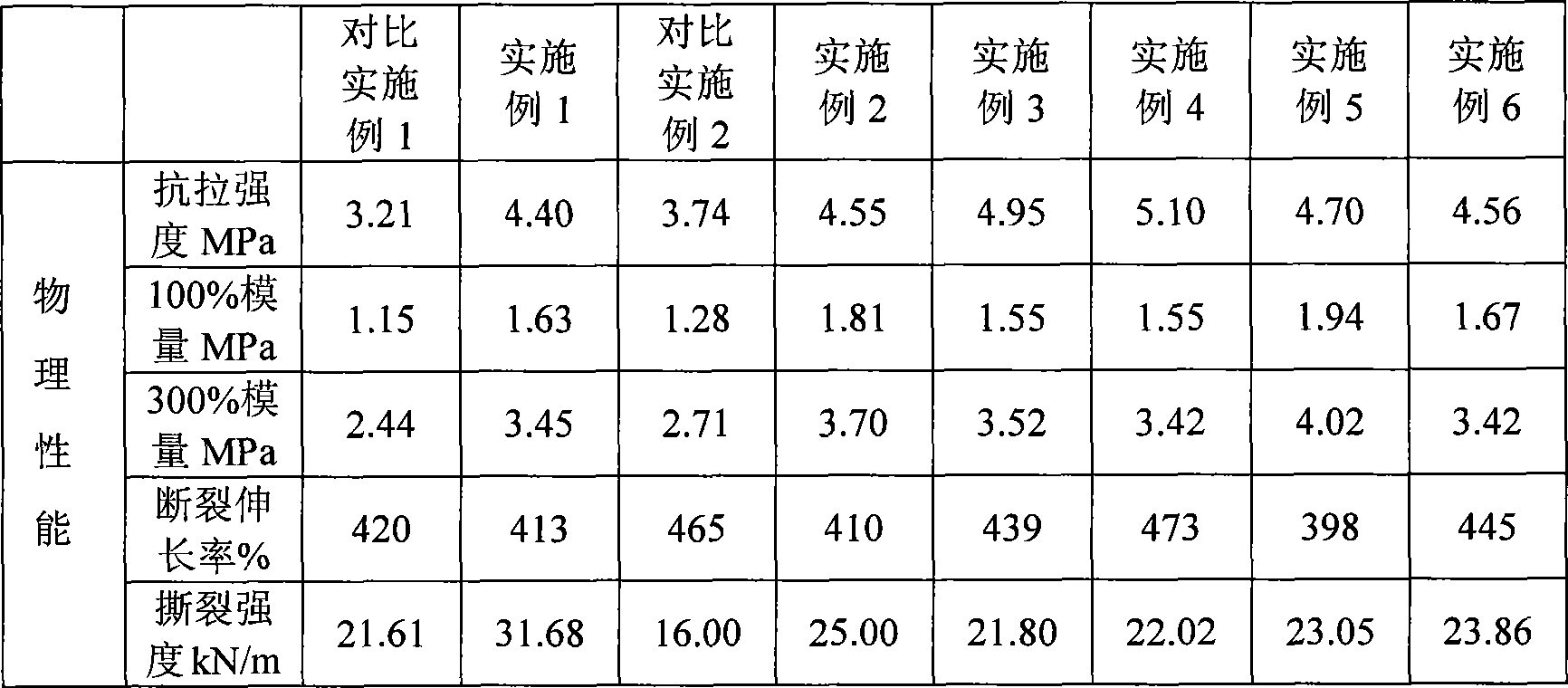

Examples

Embodiment 1

[0025] Component A: 70 kg of polyoxypropylene polyol (weight-average molecular weight 4000, functionality 2, hereinafter referred to as polyether a1), organic montmorillonite modified with dodecyl bishydroxyethyl ammonium salt Add 1.4 kg of soil (hereinafter referred to as OMMT1) and 2.1 kg of organic montmorillonite modified by dioctadecylmethylammonium salt (hereinafter referred to as OMMT2) into the reaction kettle, and stir at a temperature of 140-160°C After 2 hours, when the organic montmorillonite is uniformly dispersed in the polyether a1, the temperature is lowered to 50-60°C. Then add 30 kilograms of polyoxypropylene polyols (the weight-average molecular weight is 6000, and the functionality is 3, hereinafter referred to as polyether a2), 1.67 kilograms of ethylene glycol, 10.2 kilograms of 1,4-butanediol, 0.5 kilograms of silicone oil, water 0.24 kg, 2.4 kg of F-141b, 2.6 kg of catalyst triethylenediamine / ethylene glycol solution (Dabco EG from Air Products, USA, he...

Embodiment 2

[0029] Component A: Add 68 kg of polyether a1 and 1.5 kg of OMMT1 into the reactor, stir for 2 hours at a temperature of 140-160°C, and cool down to 50-60°C after OMMT1 is uniformly dispersed in polyether a1. Then add 14 kilograms of polyether a2, 18 kilograms of polymer polyols (the graft copolymer of propylene oxide ethylene oxide copolyether and acrylonitrile, styrene, weight-average molecular weight is 6000, and functionality is 3, hereinafter referred to as Graft copolymer polyol a3), 1.55 kilograms of ethylene glycol, 9.42 kilograms of 1,4-butanediol, 0.3 kilograms of water, 1.94 kilograms of F-141b, 0.5 kilograms of silicone oil and 2.3 kilograms of catalyst Dabco EG, add in the reactor fully Stir, mix evenly, discharge, seal and store for later use;

[0030] Component B: Put 50 kg of 4,4-diphenylmethane diisocyanate (MDI), 35 kg of carbodiimide-modified MDI and 50 kg of polyether a1 in a reaction kettle at 70-80°C for reaction 2 After 1 hour, the temperature was lower...

Embodiment 3

[0033] Other is the same as embodiment 2, OMMT1 is 0.7 kilograms, and OMMT2 is 1.4 kilograms.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com