High tensile steel for deep drawing and manufacturing method thereof

A tensile strength and deep drawing technology, applied in the field of high tensile strength steel for deep drawing and its preparation, can solve the problems of steel strength deterioration, low steel productivity, high preparation cost, etc., and achieve improved strength, smooth appearance, excellent Effects of physical properties and productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

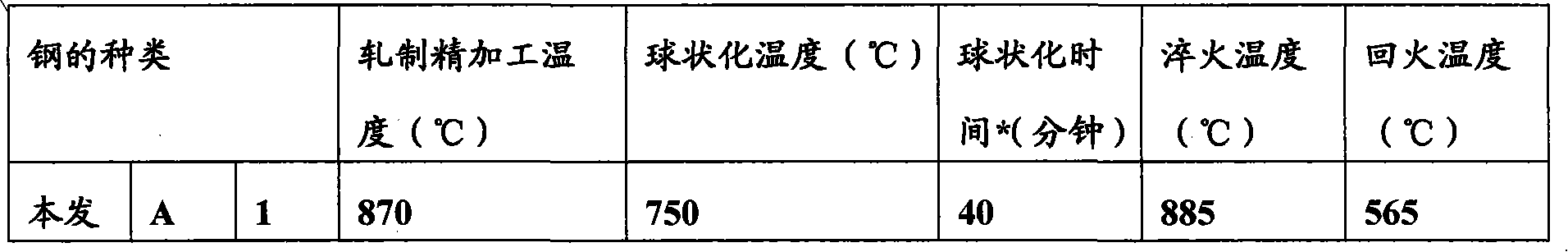

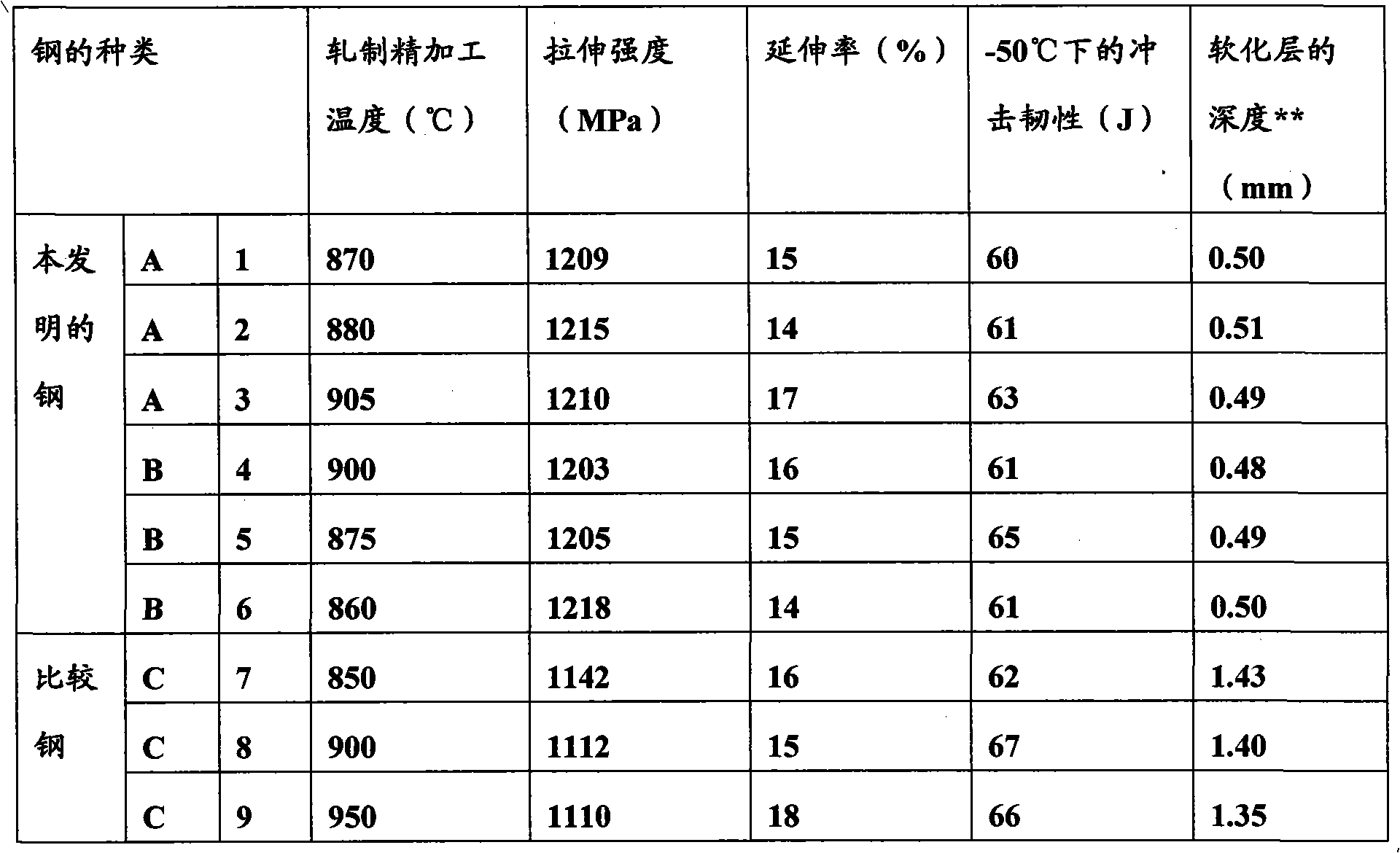

[0040] Each plate having the composition listed in Table 1 below was prepared under the conditions listed in Table 2 below, and its physical properties were measured. Then, the results are listed in Table 3 below.

[0041] Table 1

[0042]

C

Mn

Si

P

S

Ni

Cr

Mo

Ca

Ti

Al

B

this invention

Steel A

0.35

0.85

0.25

0.011

0.002

0.51

0.92

0.44

0.0016

0.015

0.0033

0.0010

this invention

Steel B

0.36

0.80

0.26

0.008

0.003

0.48

1.01

0.52

0.0012

0.012

0.0028

0.0020

Comparative steel

C

0.35

0.81

0.24

0.010

0.003

0.29

0.89

0.25

0.0007

-

0.0030

-

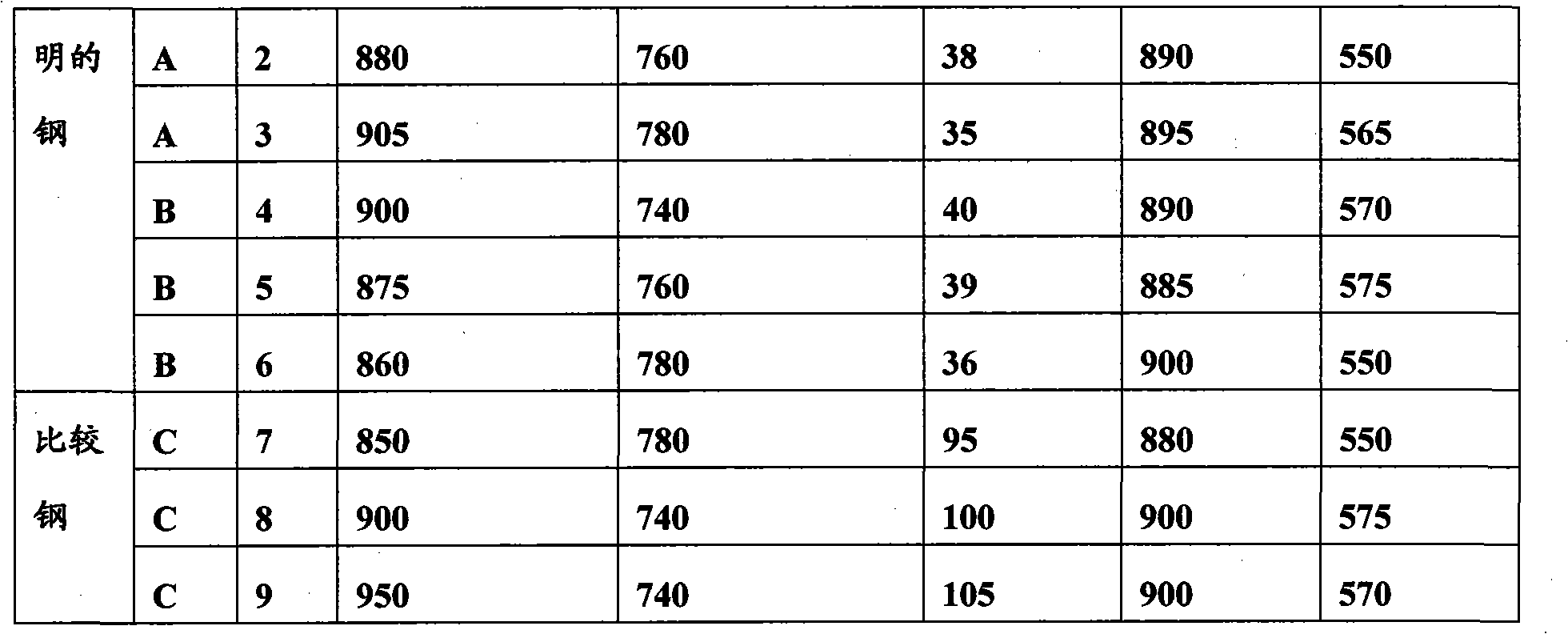

[0043] Table 2

[0044]

[0045]

[0046] *Spheroidizing time: the minimum spheroidizing heat treatment time (minutes) to obtain a steel with a tensile strength of 650Mpa after spheroidizing heat treatment

[0047] As listed in Table 2, it was found that the spheroidizing heat treatment time of the steel of the present invention was relatively shorter than that of the comparative steel. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com