345MPa-grade low-yield-ratio weather-resistant steel and preparation method thereof

A low-yield ratio, weather-resistant steel technology, applied in the production of weather-resistant steel, can solve the problems of high steel yield, increase steel carbon equivalent and welding crack sensitivity coefficient, and adverse effects on welding performance, so as to achieve good comprehensive performance, The effect of high toughness and high ductility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

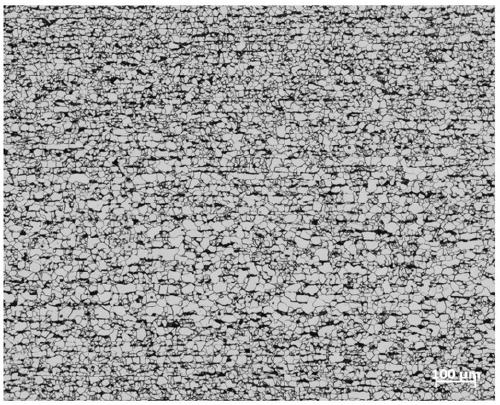

Image

Examples

Embodiment 1

[0030] The composition and mass percentage of the 345MPa grade low yield ratio weathering steel in this example are: C: 0.04%, Si: 0.50%, Mn: 0.46%, Ni: 0.20%, Cu: 0.38%, Ti: 0.018% , P: 0.09%, S: 0.0015%, Cr: 0.60%, Al: 0.04%, and the balance is Fe and unavoidable impurities. The raw materials are smelted, refined, alloyed, and treated with calcium to obtain molten steel. Slab continuous casting is carried out on the molten steel. The thickness of the cast slab is 150 mm, and the atmospheric corrosion resistance index I is 8.14. The slabs are stacked and cooled for more than 24 hours, and the slabs are soaked at 1200°C, and the temperature uniformity is less than 20°C. After heating for 150 minutes, phosphorus removal is carried out, followed by two-stage rolling. The rolling temperature in the recrystallization zone is 1080°C, the total deformation is 84%, and the thickness of the intermediate billet is controlled to be twice the thickness of the finished product. The rolli...

Embodiment 2

[0034] The composition and mass percentage of the 345MPa low yield ratio weathering steel in this example are: C: 0.09%, Si: 0.69%, Mn: 0.50%, Ni: 0.15%, Cu: 0.32%, Ti: 0.020% , P: 0.06%, S: 0.0020%, Cr: 0.35%, Al: 0.03%, and the balance is Fe and unavoidable impurities. The raw materials are smelted, refined, alloyed, and treated with calcium to obtain molten steel. The slab is continuously cast on the molten steel, and the billet thickness is 150 mm. The atmospheric corrosion resistance index I is 7.54.

[0035] The slabs are stacked and cooled for more than 24 hours, and the slabs are soaked at 1220°C, and the temperature uniformity is less than 20°C. After heating for 165 minutes, phosphorus removal is carried out, followed by two-stage rolling. The rolling temperature in the recrystallization zone is 1100°C, the total deformation is 80%, and the thickness of the intermediate billet is controlled to be 2.5 times the thickness of the finished product. The rolling start tem...

Embodiment 3

[0039] The 345MPa grade low yield ratio weathering steel in this example has the following components and mass percentages: C: 0.12%, Si: 0.65%, Mn: 0.43%, Ni: 0.21%, Cu: 0.40%, Ti: 0.015% , P: 0.08%, S: 0.0039%, Cr: 0.48%, Al: 0.02%, and the balance is Fe and unavoidable impurities. The raw materials are smelted, refined, alloyed, and treated with calcium to obtain molten steel. The slab is continuously cast on the molten steel. The thickness of the slab is 150mm. The atmospheric corrosion resistance index I is 8.04. ℃ soaking, the temperature uniformity is less than 20 ℃, dephosphorization is carried out after heating for 185min, and then two-stage rolling is carried out. The rolling temperature in the recrystallization zone is 1040°C, the total rough rolling deformation is 82%, and the thickness of the intermediate billet is controlled at 1.5 times the thickness of the finished product. The rolling start temperature in the non-recrystallization zone is 880°C, the thickness...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com