Thermoplastic polyurethane composite material used for cable and optical cable sheaths and preparation method of composite material

A thermoplastic polyurethane and composite material technology, used in plastic/resin/wax insulators, circuits, electrical components, etc., can solve the problems of poor fluidity, reduced material toughness, difficult structural materials, etc., to improve mechanical properties, improve tensile strength. Tensile strength, the effect of avoiding floating fiber phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

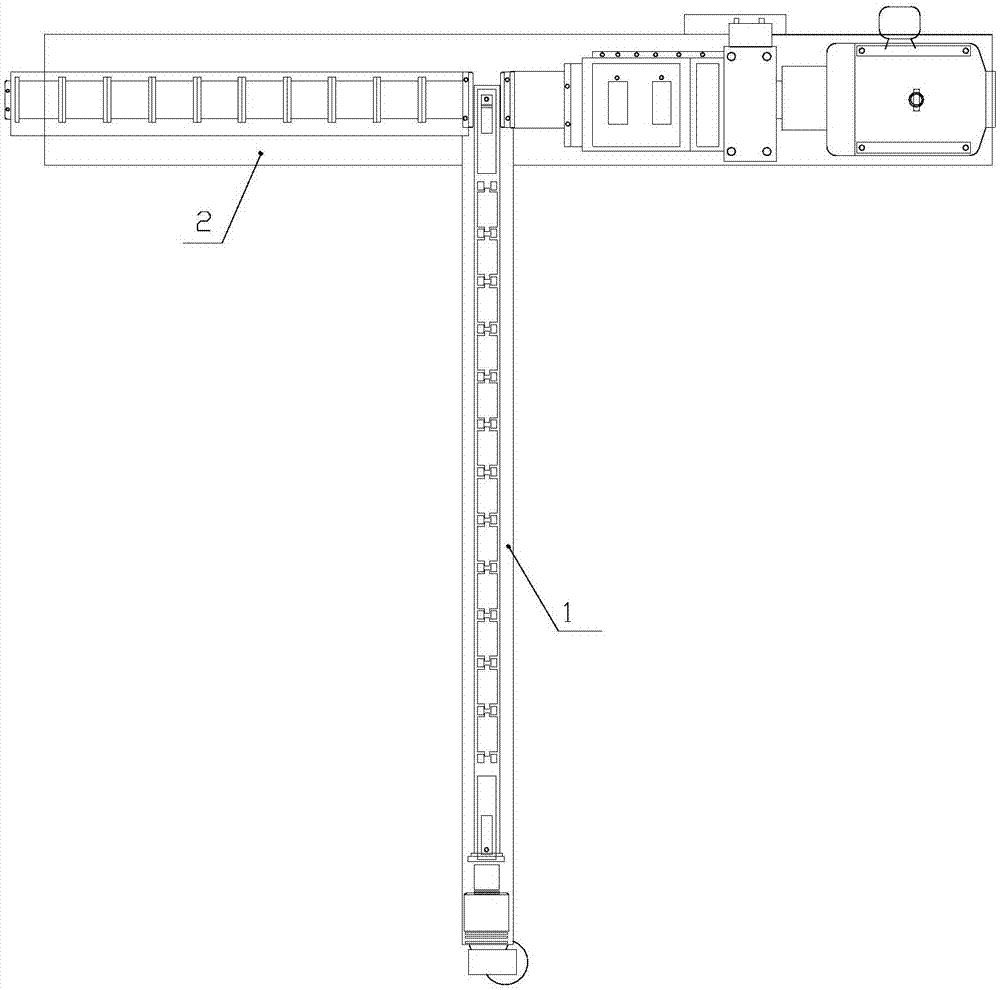

Image

Examples

Embodiment

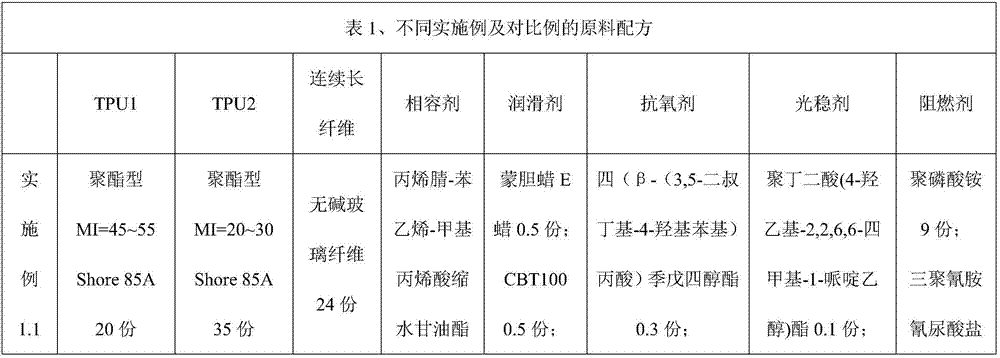

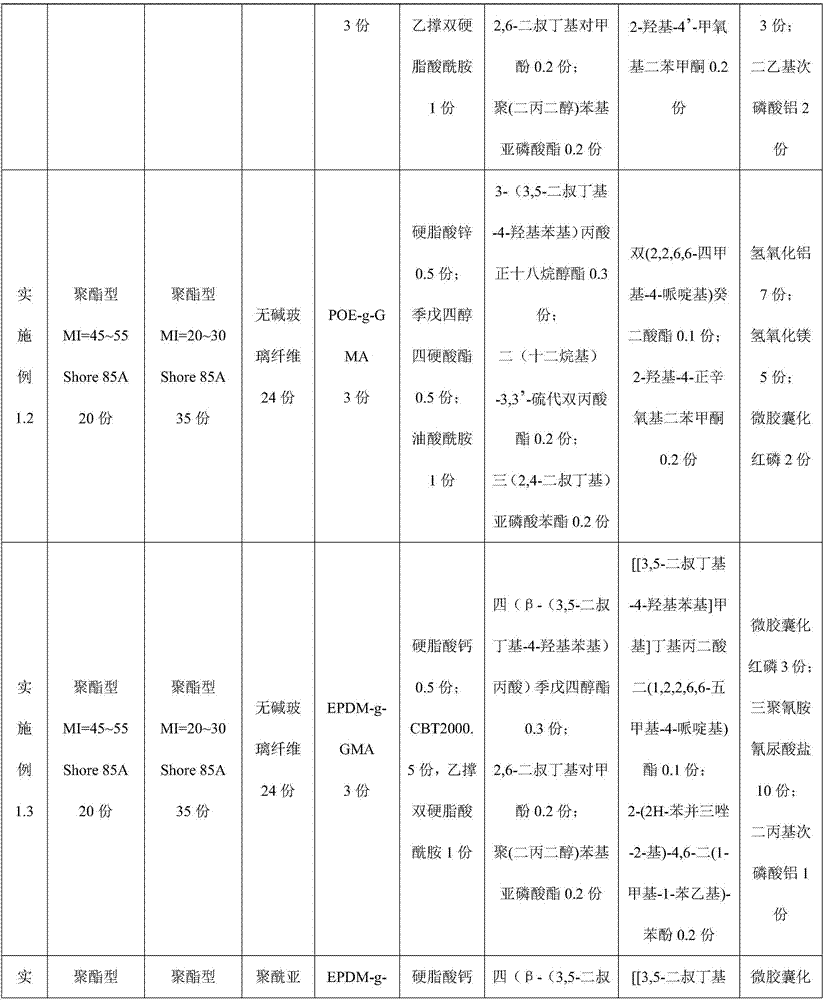

[0037] This embodiment relates to thermoplastic polyurethane composite materials for cables and optical cable sheaths and their preparation.

[0038]The raw material formula of thermoplastic polyurethane composite material for cable and optical cable sheath is:

[0039] Thermoplastic polyurethane TPU1, 15-35 parts, its melt index is 25-85g / 10min (200℃*2.16kg);

[0040] Thermoplastic polyurethane TPU2, 30-60 parts, its melt index is 5-30g / 10min (210℃*5kg);

[0041] The types of TPU1 and TPU2 are the same, and the Shore hardness is the same, both of which are 75A-60D;

[0042] Continuous long fiber, 10-30 parts;

[0043] Compatibilizer, 0.1-10 parts, the compatibilizer is a compatibilizer with epoxy groups;

[0044] Lubricants, 0.1-6 parts, the lubricants are stearates, stearic acid amides, stearates, Mongolian waxes, ring-shaped butylene terephthalate lubricants one or several mixtures;

[0045] Antioxidant, 0.2-5 parts, the antioxidant is one or a mixture of hindered phen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com