Rare earth-containing superpure high-chromium ferrite anti-wrinkle stainless steel and preparation method thereof

A high-chromium ferrite and stainless steel technology is applied in the field of rare earth-containing ultra-pure high-chromium ferrite anti-wrinkle stainless steel materials and its preparation. The effect of solving continuous casting cracking and increasing the reduction of area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

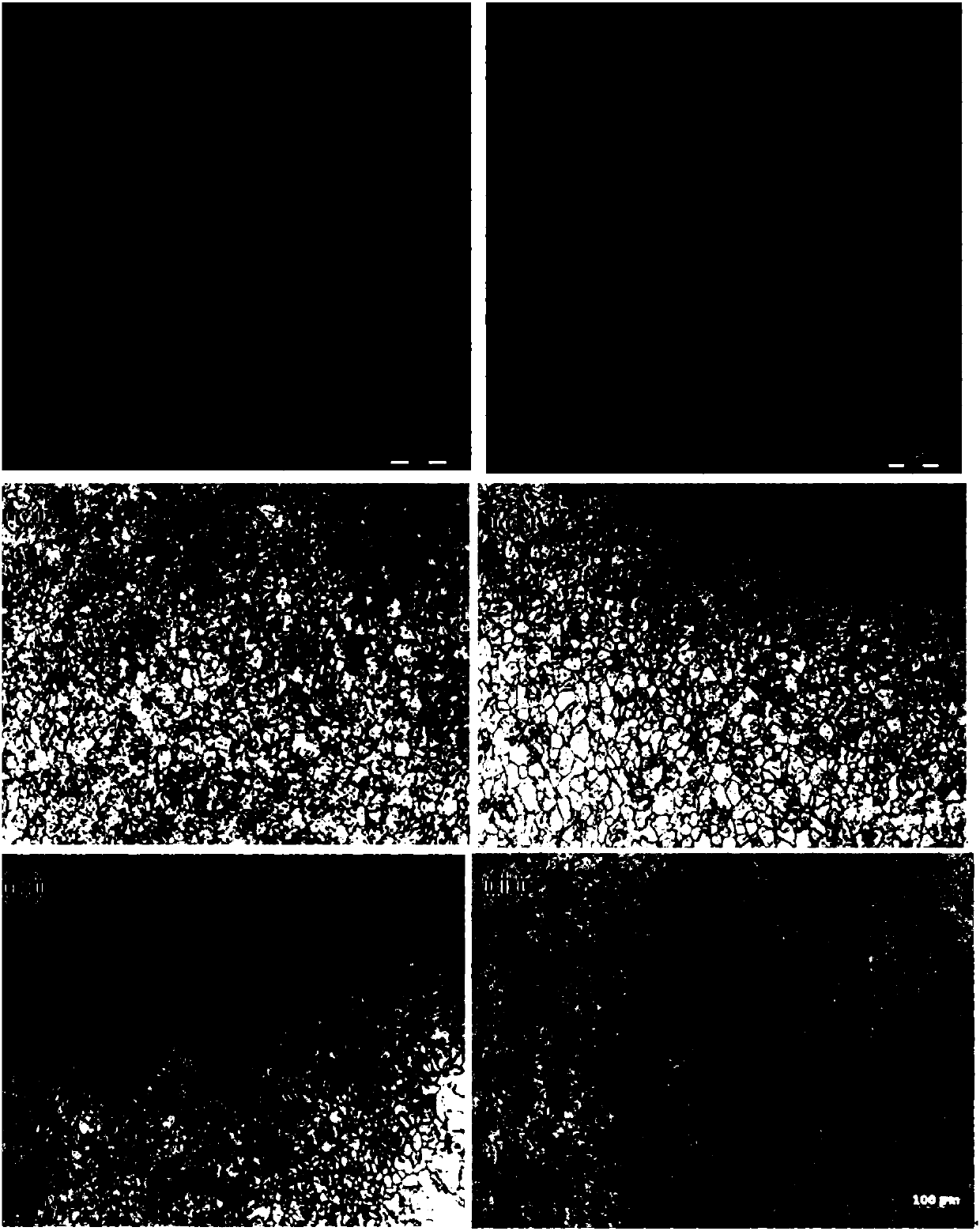

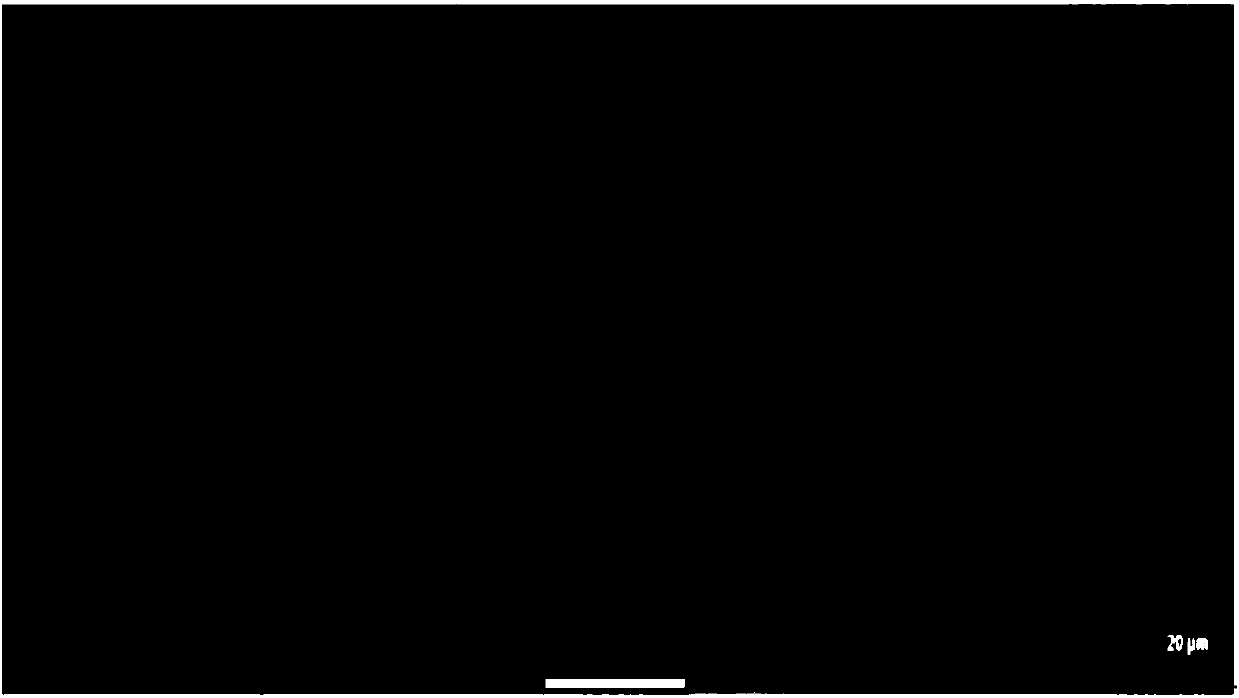

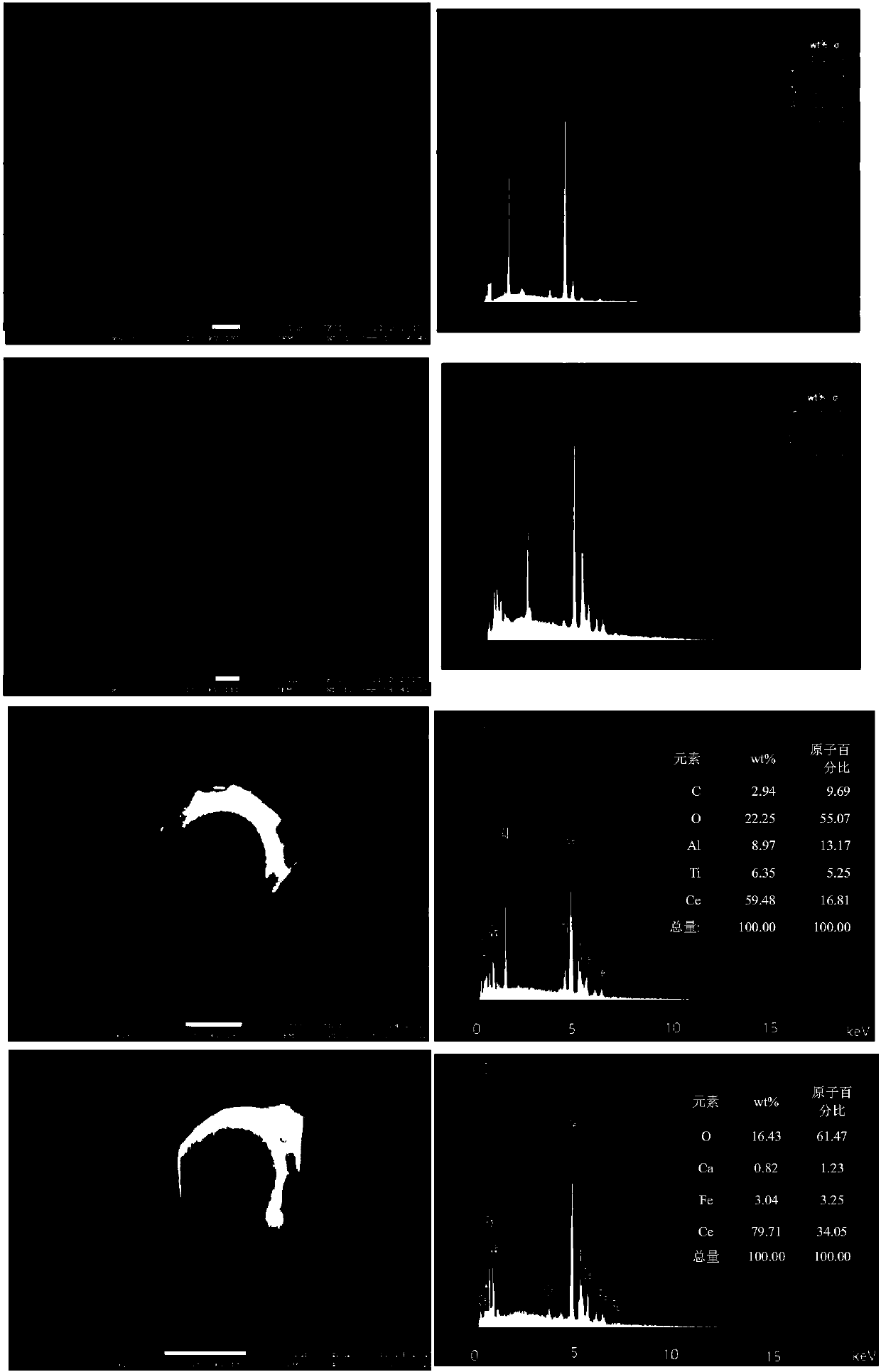

Image

Examples

Embodiment 1

[0050] High chromium ferritic stainless steel needs to strictly control the process temperature in production. Because ferritic stainless steel has no phase transformation, when it is higher than 1050°C, the ferrite grows rapidly, which seriously affects the performance of the steel; at the same time, high-chromium ferritic stainless steel is easy to precipitate σ, Laves, etc. in the temperature range of 600-850°C Harmful precipitates, σ and Laves are chromium-rich phases, and their formation will cause the matrix to be poor in chromium, thereby seriously reducing the corrosion resistance of steel; at the same time, the hard and brittle σ and Laves phases will also affect the processing and mechanical properties of steel . The heat treatment process after hot rolling and cold rolling is to eliminate harmful phases. Considering comprehensively, and through a large number of experimental studies, the preparation of the rare earth-containing ultra-pure high-chromium ferritic ant...

Embodiment 2-6

[0064] In this example, on the basis of Example 1, the content of the chemical components added in Table 1 for the preparation of rare earth-containing ultra-pure high-chromium ferrite with good wrinkle resistance is specifically adopted, wherein the rare earth element RE is preferably pure Ce , pure Ce refers to the refined Ce block; according to the steel smelting, hot rolling, heat treatment and other process parameters in Table 2, the rare earth-containing ultra-pure high-chromium ferritic wrinkle-resistant stainless steel was prepared.

[0065] Table 1. Chemical composition list (unit is weight percent %)

[0066] serial number

C

N

Si

mn

P

S

Cr

Mo

Nb

Ti

Ni

O

RE

Example 2

0.0042

0.0074

0.35

0.38

0.0097

0.0041

26.69

3.12

0.26

0.20

2.44

0.0029

0.013

Example 3

0.0064

0.0084

0.42

0.39

0.0092

0.0033

27.03

3.35

0.30

0.21

2.49

0.0026

0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com