High-wear-resistance cermet coating

A cermet coating and cermet technology, which is applied in the field of wear-resistant steel, can solve the problems that the hardness needs to be further improved, the ion implantation tungsten infiltration process is complicated, and the production efficiency is low, so as to reduce the friction coefficient, reduce the cost, and reduce the cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

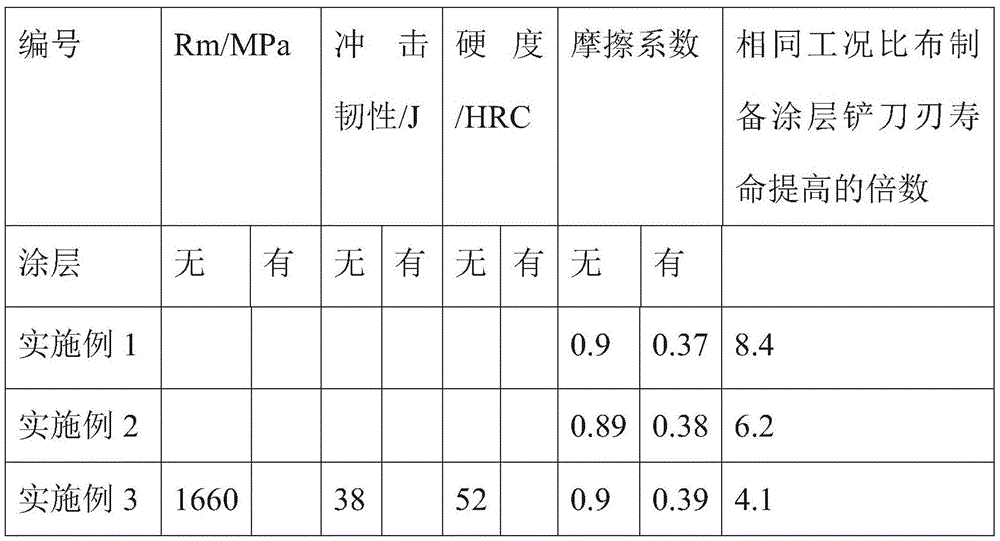

Embodiment 1

[0023] Adopt No. 45 steel to prepare a shovel blade with a thickness of 15mm, and prepare a 10wt.% Ni-based alloy with a thickness of 5mm on the surface to coat a high wear-resistant cermet coating of 90wt.% Si-Al-C-N amorphous particles to obtain a 25mm thick The shovel blade with high wear-resistant cermet coating; the high wear-resistant shovel edge cermet coating is prepared according to the following procedures:

[0024] 1) In terms of weight percentage, Ni-based alloy powder: 10wt.%, Si-Al-C-N nano-amorphous particles: 90wt.%, after mixing, put it into a high-energy ball mill for ball milling for 2 hours to form a cermet powder slurry ; Among them, the weight percentage of elements in Ni-based alloy powder: Ni: 50%, Fe: 33%, Cr: 10%, Mn: 5.434%, Si: 1%, C: 0.5%, B: 0.006%, P: 0.04 %, S: 0.02%, powder particle size 35μm, Si-Al-C-N amorphous particle size 18μm.

[0025] 2) Evenly coat the cermet powder slurry on the surface of the spatula blade with a coating thickness of...

Embodiment 2

[0031] Prepare a 1mm thick 15wt.% Ni-based alloy coated 85wt.% Si-Al-C-N amorphous particle high wear-resistant cermet coating on the surface of a 30mm thick SHSC-3 spatula developed by Komatsu Corporation in Japan to obtain a 32mm thick The shovel blade with high wear-resistant cermet coating; the high wear-resistant shovel edge cermet coating is prepared according to the following procedures:

[0032] 1) In terms of weight percentage, Ni-based alloy powder: 15wt.%, Si-Al-C-N nano-amorphous particles: 85wt.%, after mixing, put it into a high-energy ball mill for ball milling for 2 hours to form a cermet powder slurry ; Among them, the weight percentage of elements in Ni-based alloy powder: Ni: 60%, Fe: 20%, Cr: 18%, Mn: 4%, Mo: 1.25%, Si: 0.5%, C: 0.2%, B: 0.005 %, P: 0.03%, S: 0.015%, powder particle size 30μm, Si-Al-C-N amorphous particle size 12μm.

[0033] 2) Evenly coat the cermet powder slurry on the surface of the spatula blade with a coating thickness of 0.3mm;

[0...

Embodiment 3

[0039] Using the Chinese invention patent with publication number CN103205639A to prepare a 35mm thick spatula blade, prepare a 10mm thick 20wt.% Ni-based alloy coated 80wt.% Si-Al-C-N amorphous particle high wear-resistant cermet coating on the surface, Obtain a 55mm thick shovel blade with a high wear-resistant cermet coating; the high wear-resistant shovel edge cermet coating is prepared according to the following procedures:

[0040]1) In terms of weight percentage, Ni-based alloy powder: 20wt.%, Si-Al-C-N nano-amorphous particles: 80wt.%, after mixing, put it into a high-energy ball mill for ball milling for 2 hours to form a cermet powder slurry ; Among them, the weight percentage of elements in Ni-based alloy powder: Ni: 55%, Fe: 26%, Cr: 14%, Mn: 2.4%, Mo: 2.267%, Si: 0.2%, C: 0.1%, B: 0.003 %, P: 0.02%, S: 0.01%, powder particle size 35 μm, Si-Al-C-N amorphous particle size 15 μm.

[0041] 2) Evenly coat the cermet powder slurry on the surface of the spatula blade wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com