Steel for shield machine cutting tool and manufacturing method thereof

A shield machine tool and manufacturing method technology, which is applied in the direction of manufacturing tools, furnace types, furnaces, etc., can solve the problems of poor comprehensive performance of tool steel, reduce raw material costs, refine and homogenize the microstructure, and ensure Effects of tissue hardening and thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

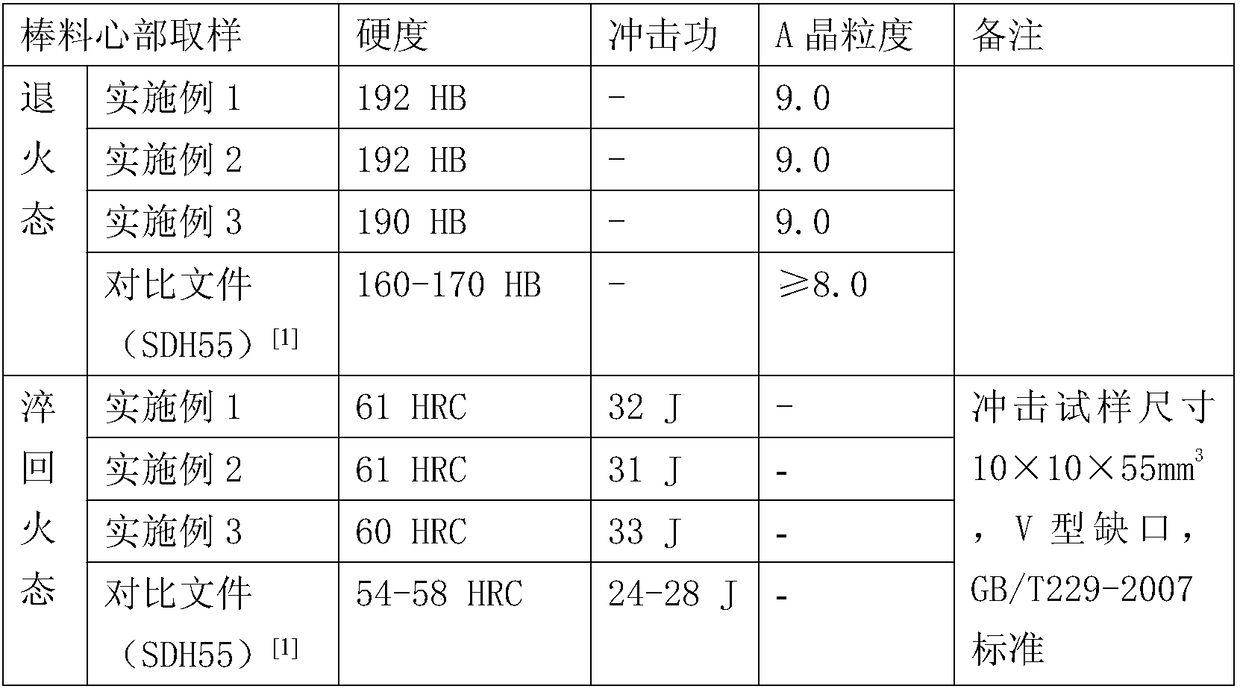

Embodiment 1

[0054] A steel for a shield machine tool, the composition and mass percentage of the steel for a shield machine tool are:

[0055] C: 0.72%, Si: 0.18%, Mn: 0.48%, Cr: 5.18%, Mo: 2.32%, V: 0.50%, P<0.020%, S<0.005%, the balance is Fe and unavoidable impurities.

[0056] A manufacturing method of steel for a shield machine tool, the manufacturing method comprising the following steps:

[0057] The first step: induction furnace smelting, batching the mass percentage of each alloy raw material component element of the steel for the shield machine tool, the chemical composition of the alloy is composed of the following elements: C: 0.72%, Si: 0.18%, Mn: 0.48%, Cr: 5.18%, Mo: 2.32%, V: 0.50%, the balance is Fe and unavoidable impurity elements, of which impurity elements P<0.020%, S<0.005%; Put it into an induction furnace for smelting, and then cast it into a Φ360mm×2200mm electrode rod;

[0058] The second step: remelting in an electroslag furnace. The electrode rod prepared in ...

Embodiment 2

[0069] A steel for a shield machine tool, the composition and mass percentage of the steel for a shield machine tool are:

[0070] C: 0.75%, Si: 0.25%, Mn: 0.54%, Cr: 5.06%, Mo: 2.40%, V: 0.60%, P<0.020%, S<0.005%, and the balance is Fe and unavoidable impurities.

[0071]A manufacturing method of steel for a shield machine tool, the manufacturing method comprising the following steps:

[0072] The first step: induction furnace smelting, batching the mass percentage of each alloy raw material component element of the steel for the shield machine tool, the chemical composition of the alloy is composed of the following elements: C: 0.75%, Si: 0.25%, Mn: 0.54%, Cr: 5.06%, Mo: 2.40%, V: 0.60%, the balance is Fe and unavoidable impurity elements, of which impurity elements P<0.020%, S<0.005%; Put it into an induction furnace for melting, and then cast it into a Φ280mm×2500mm electrode rod;

[0073] The second step: remelting in an electroslag furnace. The electrode rod prepared i...

Embodiment 3

[0084] A steel for a shield machine tool, the composition and mass percentage of the steel for a shield machine tool are:

[0085] C: 0.73%, Si: 0.20%, Mn: 0.51%, Cr: 5.05%, Mo: 2.35%, V: 0.56%, P<0.020%, S<0.005%, the balance is Fe and unavoidable impurities.

[0086] A manufacturing method of steel for a shield machine tool, the manufacturing method comprising the following steps:

[0087] The first step: induction furnace smelting, batching the mass percentage of each alloy raw material component element of the shield machine tool steel, the chemical composition of the alloy is composed of the following elements: C: 0.73%, Si: 0.20%, Mn: 0.51%, Cr: 5.05%, Mo: 2.35%, V: 0.56%, the balance is Fe and unavoidable impurity elements, of which impurity elements P<0.020%, S<0.005%; Put it into an induction furnace for smelting, and then cast it into a Φ400mm×2100mm electrode rod;

[0088] The second step: remelting in an electroslag furnace. The electrode rod prepared in the firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com