Ultrahigh-strength engineering machinery steel Q890D and production method thereof

A technology of engineering machinery and production methods, which is applied in the fields of iron and steel metallurgy and rolling, can solve the problems of high process costs and high selling prices, and achieve the effects of shortening the production process, reducing production costs, and satisfying mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

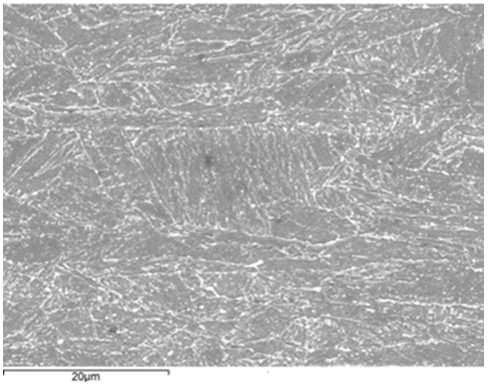

Image

Examples

Embodiment Construction

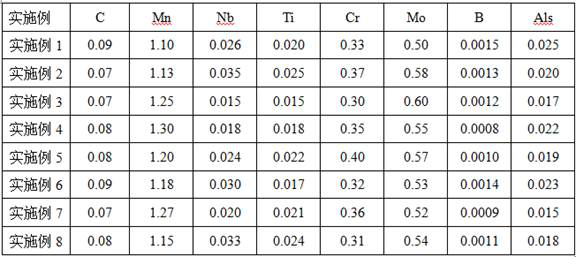

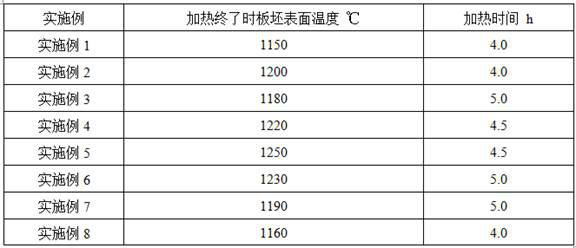

[0025] The present invention will be described in further detail below in conjunction with specific embodiments.

[0026] A production method of Q890D, an ultra-high-strength engineering machinery steel, comprising slab heating, controlled rolling, DQ on-line quenching+ACC rapid cooling, and tempering heat treatment, specifically as follows:

[0027] (1) Slab heating: the slab is heated in a walking furnace, the surface temperature at the end of the slab heating is controlled within the range of 1150-1250°C, and the heating time is controlled within 4-5 hours.

[0028] (2) Controlled rolling: CR rolling is adopted, the starting rolling temperature is 1080-1100°C; the final rolling temperature of the first stage is ≥980°C, the starting rolling temperature of the second stage is ≤950°C, and the cumulative reduction ratio of finishing rolling is ≥66 %, the final rolling temperature is 840~880℃.

[0029] (3) On-line quenching treatment: DQ+ACC method is adopted. After the steel p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| phase transition temperature | aaaaa | aaaaa |

| microhardness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com