Micro inertial switch with Z-shaped beam structure

A technology of micro-inertia and beam structure, which is applied in the field of micro-inertia switches, can solve the problems that the inertial force of rectangular spiral beams cannot be ignored, the elastic coefficient cannot be made small, and the anti-lateral overload protection structure cannot be made, so as to improve the environment of anti-vibration and shock Adaptability, improving the ability to resist lateral overload, and improving the effect of resisting lateral overload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in detail below in conjunction with the accompanying drawings.

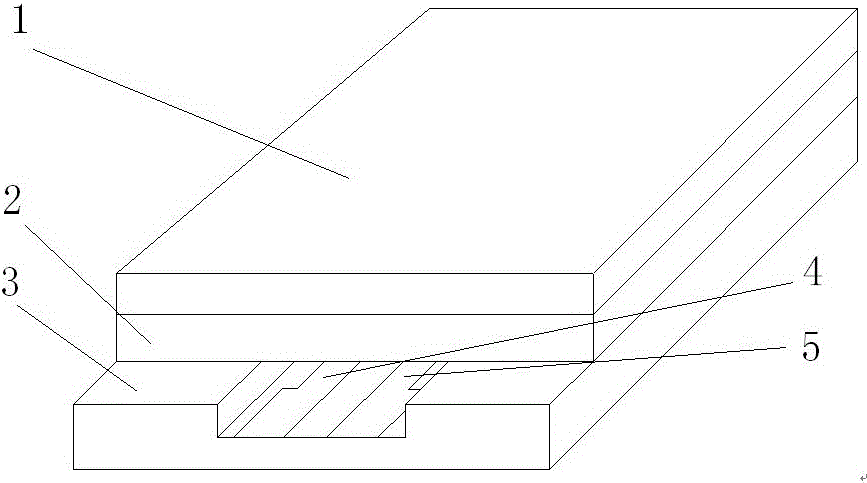

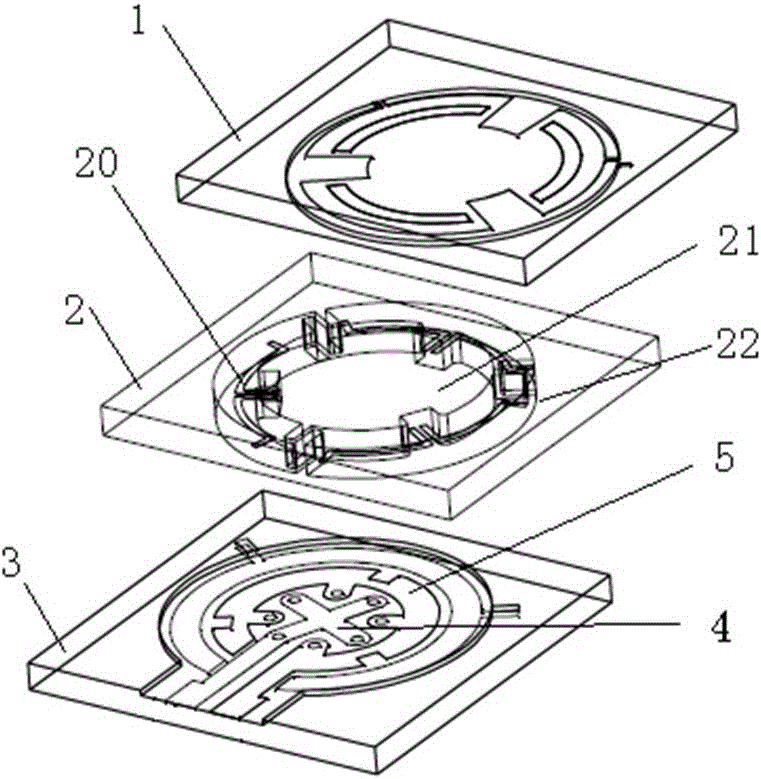

[0027] like Figure 1-Figure 5 As shown, the micro-inertial switch of the Z-beam structure of the present invention includes a cover plate 1, a structural layer 2 and a base 3, and the cover plate 1, the structural layer 2, and the base 3 are connected by bonding from top to bottom, and the cover plate 1 and the material of the substrate 3 is glass, and the material of the structural layer 2 is silicon;

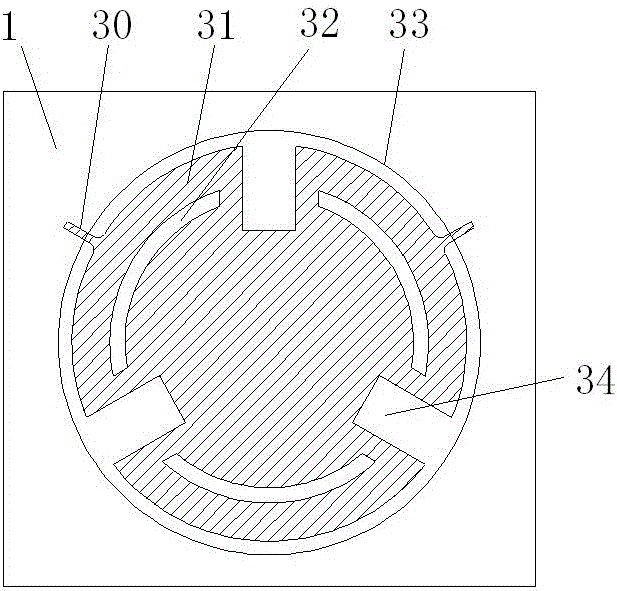

[0028] The structural layer 2 includes a mass block 21, a Z-shaped beam 20 and a silicon frame 22. The center of the structural layer 2 is a cylindrical mass block 21, the inner ring of the structural layer 2 is hollow, and the outer ring of the structural layer 2 is rectangular. Silicon frame 22; the center of the lower surface of the mass block 21 is covered with a contact electrode 40; in the inner circle of the structural layer 2, every two symmetrically arrang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com