Self-lubricating modular metal roller electric locomotive pantograph head with damping structure

A technology of metal rollers and electric locomotives, applied in the field of rail transportation, can solve problems such as wear resistance, poor impact resistance, accelerated aging of skateboards, arc ablation damage of carbon skateboards, etc., to achieve high wear resistance, hard heat dissipation performance, The effect of reducing the probability of ablation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

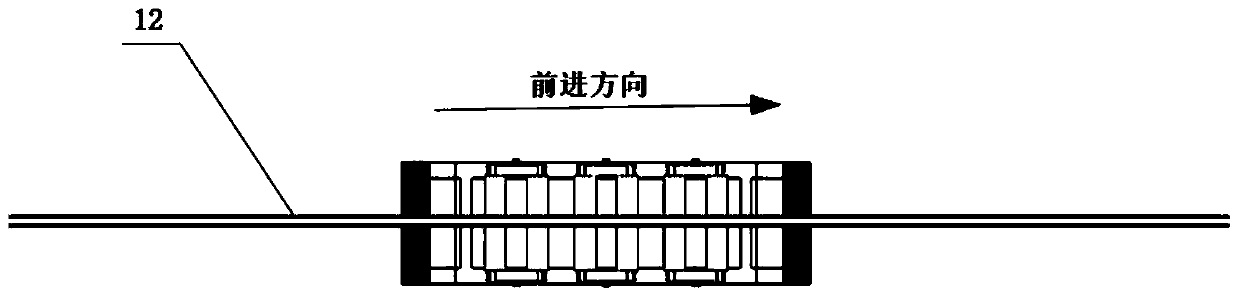

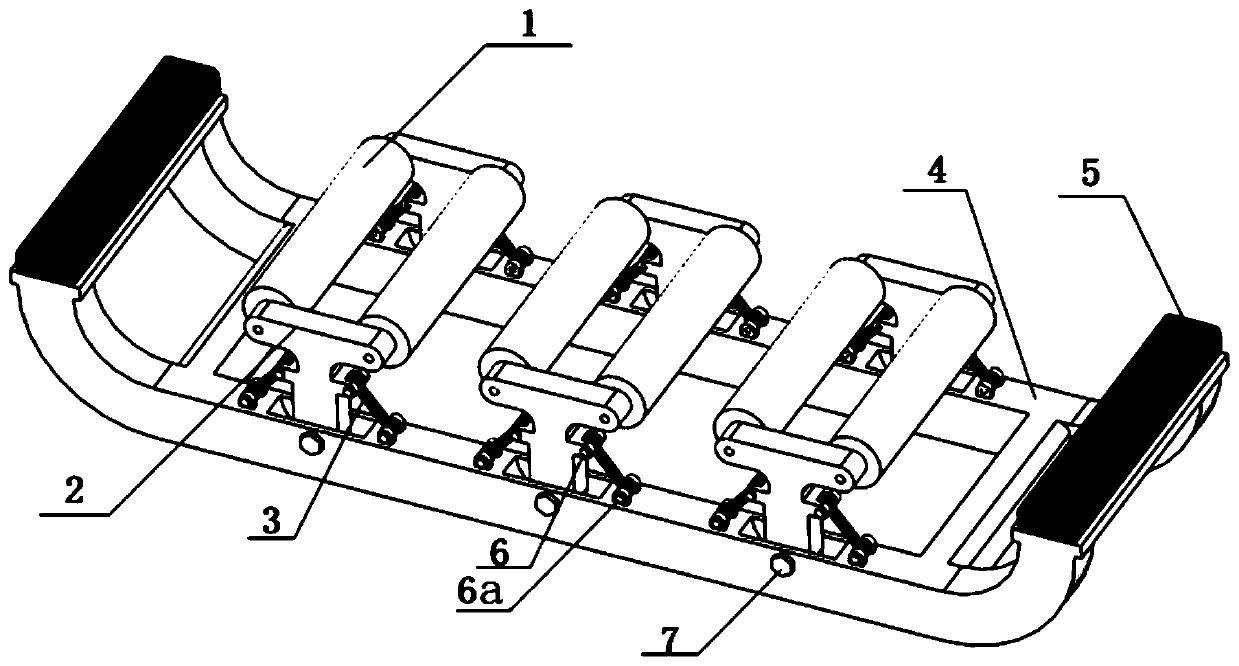

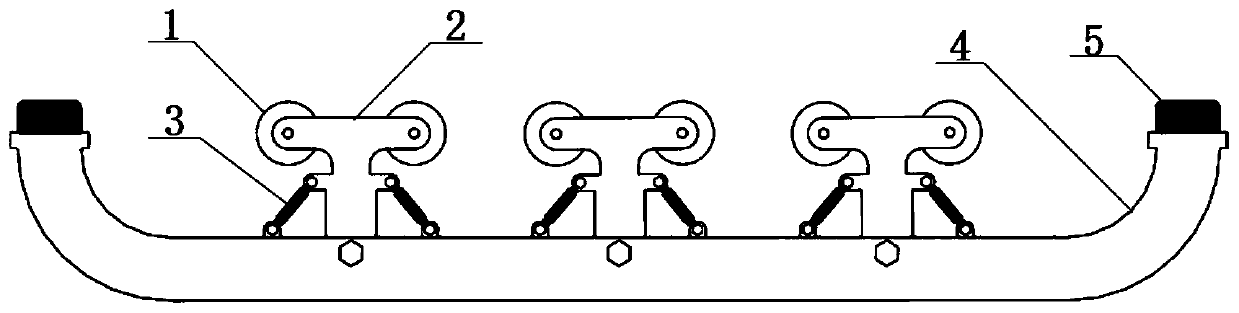

[0030] figure 2 , image 3 Shown, a self-lubricating modular metal drum electric locomotive pantograph head with shock absorbing structure, the insulating base 4 is composed of left and right vertical plates and a horizontal bottom plate, and the upper end surfaces of the left and right vertical plates of the insulating base 4 are A pure carbon sliding plate 5 is detachably installed respectively for contacting with the rigid contact line 12 to play a lubricating role; the rectangular horizontal bottom plate of the insulating base 4 is longitudinally provided with more than one group of metal rollers 1, each group of metal rollers 1 The setting method is as follows: the lower parts of the vertical sections of the two "T"-shaped insulating supports 2 are respectively extended into a groove on the horizontal base, and the fixing bolts 7 screwed in from the outer side of the horizontal base plate are sleeved through the holes on them. On the left and right sides of each insulatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com