Modified polylactic acid commixture and preparation method thereof

A technology for polylactic acid and blends, which is applied in the field of modified polylactic acid blends and their preparation, can solve the problems of unguaranteed mechanical properties, and achieve simple and easy preparation methods, wide application, and guaranteed mechanical properties Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

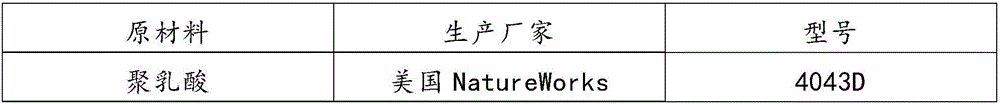

Embodiment 1

[0049] Step 1: Prepare raw materials according to the following components and parts by weight: 90kg polylactic acid, 10kg ethylene-butyl acrylate-glycidyl methacrylate, 1kg hexamethyldisilazane modified nano-silica, and 0.1kg Antioxidant 1010;

[0050] Step 2: drying the polylactic acid in step 1 to a moisture content of less than 1500ppm;

[0051] Step 3: Mix the dried polylactic acid in step 2 with ethylene-butyl acrylate-glycidyl methacrylate, hexamethyldisilazane modified nano-silica, and antioxidant 1010 in step 1 , and added to a twin-screw extruder, extruded at a temperature of 180-220° C., while cooling and granulating, the polylactic acid blend of Example 1 was obtained.

Embodiment 2

[0053] Step 1: Prepare raw materials according to the following components and parts by weight: 90kg polylactic acid, 10kg ethylene-methacrylic acid ionomer, 1kg hexamethyldisilazane modified nano-silica, 0.1kg antioxidant 1010 , and 0.1kg 4,4'-bis(phenylisopropyl)diphenylamine;

[0054] Step 2: drying the polylactic acid in step 1 to a moisture content of less than 1500ppm;

[0055] Step 3: Combine the dried polylactic acid in step 2 with the ionic polymer of ethylene-methacrylic acid in step 1, hexamethyldisilazane modified nano-silica, antioxidant 1010, and 4,4 '-di(phenylisopropyl)diphenylamine is mixed, and added to a twin-screw extruder, extruded at a temperature of 180-220°C, and simultaneously cooled and granulated to obtain the polylactic acid blend of Example 2 thing.

Embodiment 3

[0057] Step 1: Prepare raw materials according to the following components and parts by weight: 60kg polylactic acid, 40kg methyl methacrylate-butadiene-styrene copolymer, 5kg dimethyldichlorosilane modified nano-silica, 0.1kg Antioxidant 1010, 0.1kg3-aryl-benzofuranone, and 20kg glass fiber;

[0058] Step 2: drying the polylactic acid in step 1 to a moisture content of less than 1500ppm;

[0059] Step 3: Combine the dried polylactic acid in step 2 with the methyl methacrylate-butadiene-styrene copolymer in step 1, dimethyldichlorosilane modified nano-silica, antioxidant 1010, 3-Aryl-benzofuranone is mixed and fed into the twin-screw extruder. The glass fiber is fed from the side feeding port in the middle of the screw extruder, extruded at a temperature of 180-220°C, and cooled and granulated at the same time. That is, the polylactic acid blend of Example 3 was obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com