Double-glass photovoltaic module with back glass being separated

A double-layer glass, photovoltaic module technology, applied in photovoltaic power generation, electrical components, semiconductor devices, etc., can solve the problems of diode size limitation, sizing difficulties, local stress concentration of glass, etc., to solve the cost increase, solve the insulation performance and The effect of poor impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

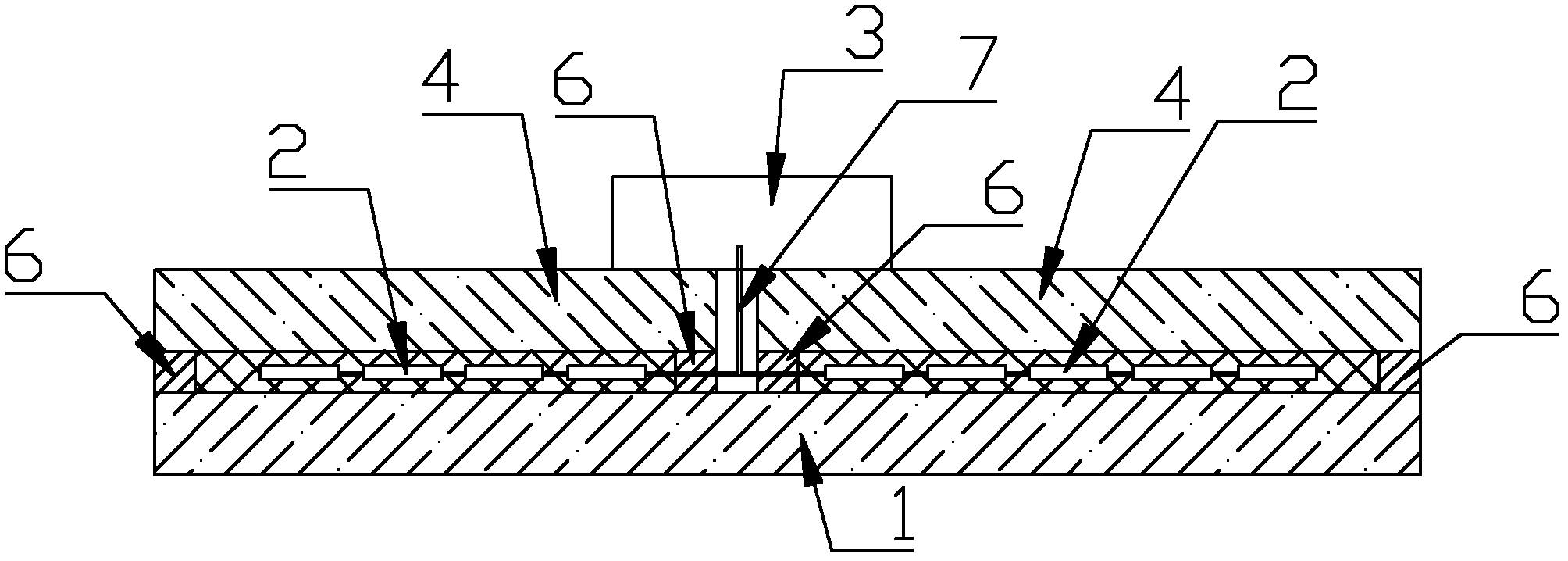

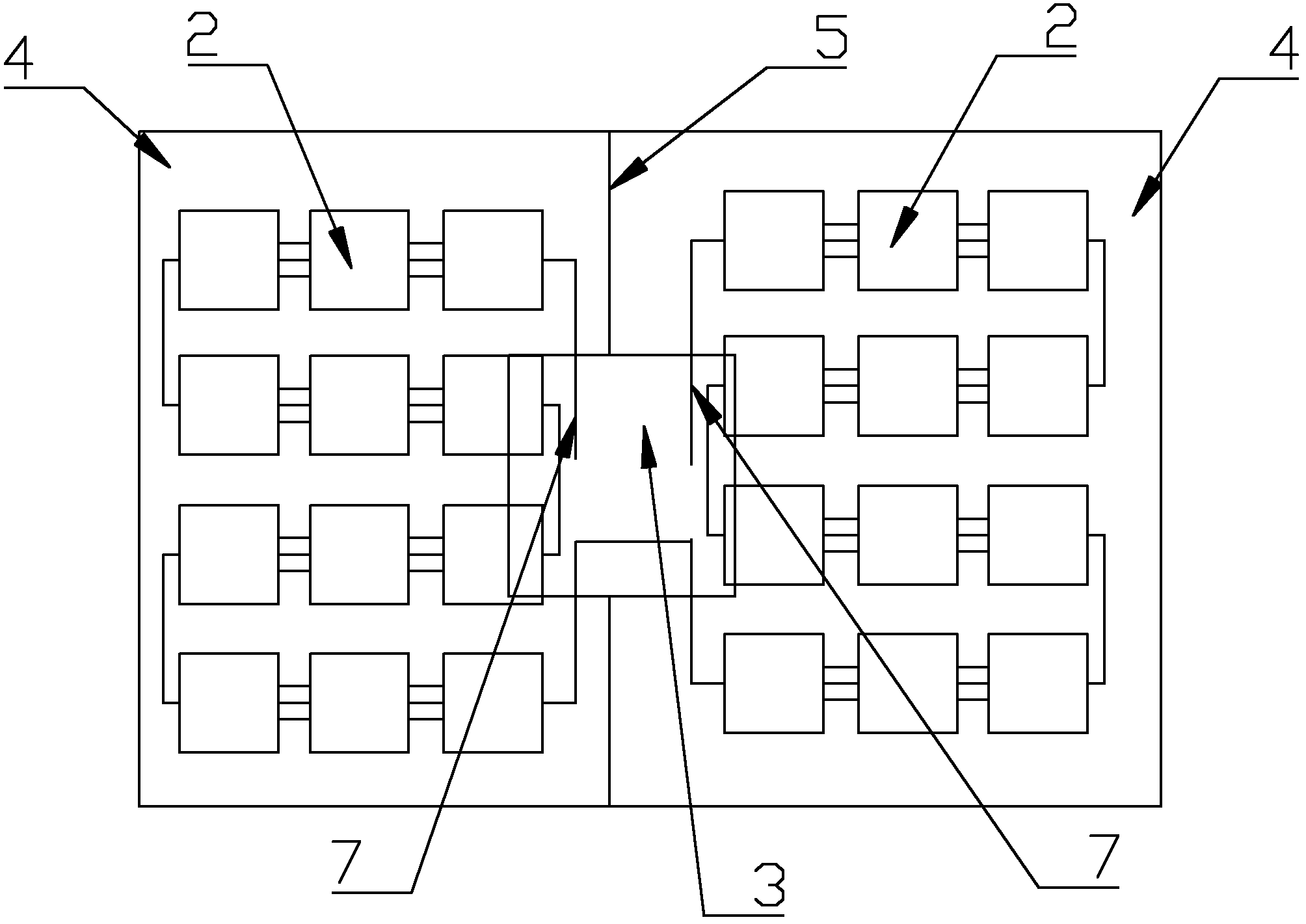

[0030] Such as figure 1 , 2 , 3 and 4, a double-layer glass photovoltaic module with separate back glass, including a panel 1, a battery string 2 and a back plate, the battery string 2 is encapsulated between the panel 1 and the back plate by EVA, PVB, and the battery string 2 The bus bar 7 of the battery string 2 is connected to the junction box 3 arranged on the back panel, and the back panel is formed by splicing two back panel units 4 into a whole, and the bus bar 7 of the battery string 2 is drawn out through the splicing seam 5 of the back panel unit 4, Connect with junction box 3. The battery string 2 includes two independent parts on the left and right. The two parts of the battery string 2 are led out through their respective bus bars 7. The two backplane units 4 are respectively covered on the two parts of the battery string 2. The respective bus bars 7 Lead out through the splicing seam 5 between the two backplane units 4, and connect with the junction box 3, and ...

Embodiment 2

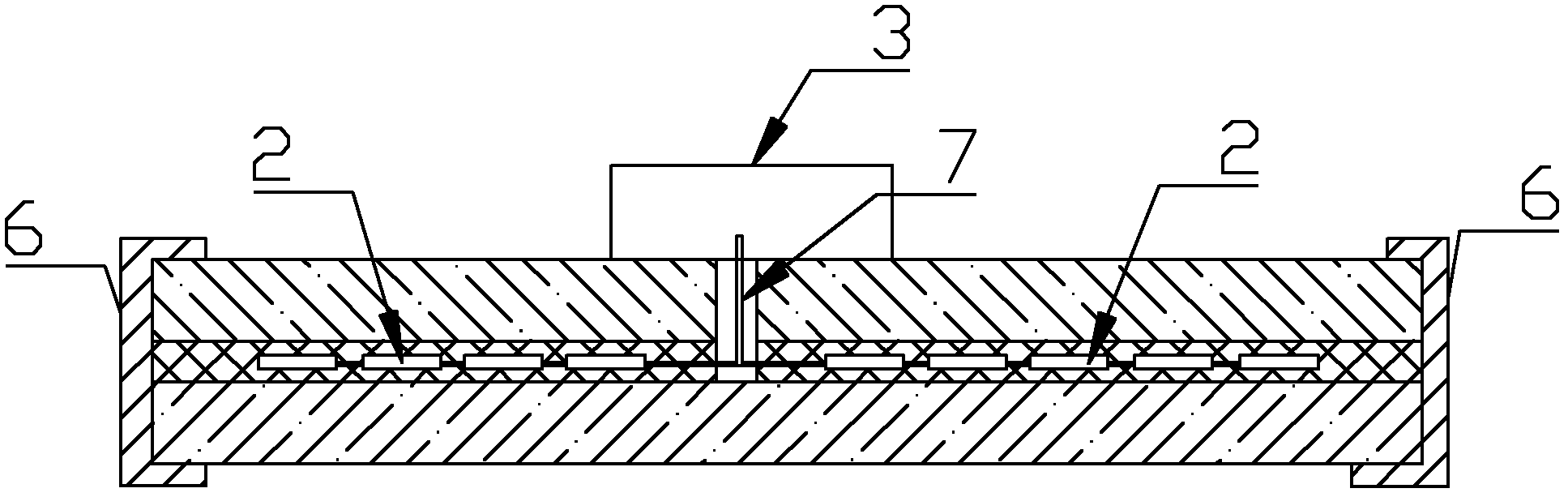

[0035] A double-layer glass photovoltaic module with separate back glass, including a panel 1, battery strings 2 and a backplane, the battery strings 2 are packaged between the panel 1 and the backplane, the bus bars 7 of the battery strings 2 are connected to the backplane The junction box 3 is connected, the backplane is formed by splicing two backplane units 4 into a whole, the battery string 2 is a whole, one of the two backplane units 4 covers the entire battery string 2, and the other covers the back of the assembly In areas other than the battery string 2 area, the bus bar 7 is led out through the splicing seam 5 between the two backplane units 4 and connected to the junction box 3 .

[0036] Such as Figure 5 , 6 As shown in and 7, the two backplane units 4 are a separate small glass and a large glass, and the joint 5 of the two backplane units 4 is located at the end position of the back of the assembly.

[0037] The combined length and width of the two glasses are ...

Embodiment 3

[0043] Compared with Example 2, the battery string 2 is an integral battery string 2, but the two backplane units 4 are covered on the battery sheet, the splicing seam 5 is far away from the end position of the assembly, and the bus bar at the end of the battery string 2 7 is led back from the end position of the assembly to the splicing place in the middle of the assembly and then drawn out from the splicing seam 5 of the two backplane units 4 .

[0044] The key point of the lamination process of the components of the above-mentioned embodiments 1, 2 and 3 is to ensure that the two backplane units 4 on the back are not displaced during the lamination process, so two process methods can be used

[0045] 1. Adhesive adhesive tape at different positions between the two backplane units 4 and between the backplane unit 4 and the panel 1 to perform a lamination.

[0046] 2. One of the backplane units 4 and the panel 1 are laminated once, and then another backplane unit 4 is placed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com