High-toughness and high-shock-resistance polyvinyl chloride cable material and preparation method thereof

A polyvinyl chloride cable, high impact resistance technology, applied in the field of high toughness and high impact polyvinyl chloride cable material and its preparation, can solve the problems of poor toughness and impact resistance, and achieve the solution of poor impact resistance and toughness , high impact resistance and toughness, good heat resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

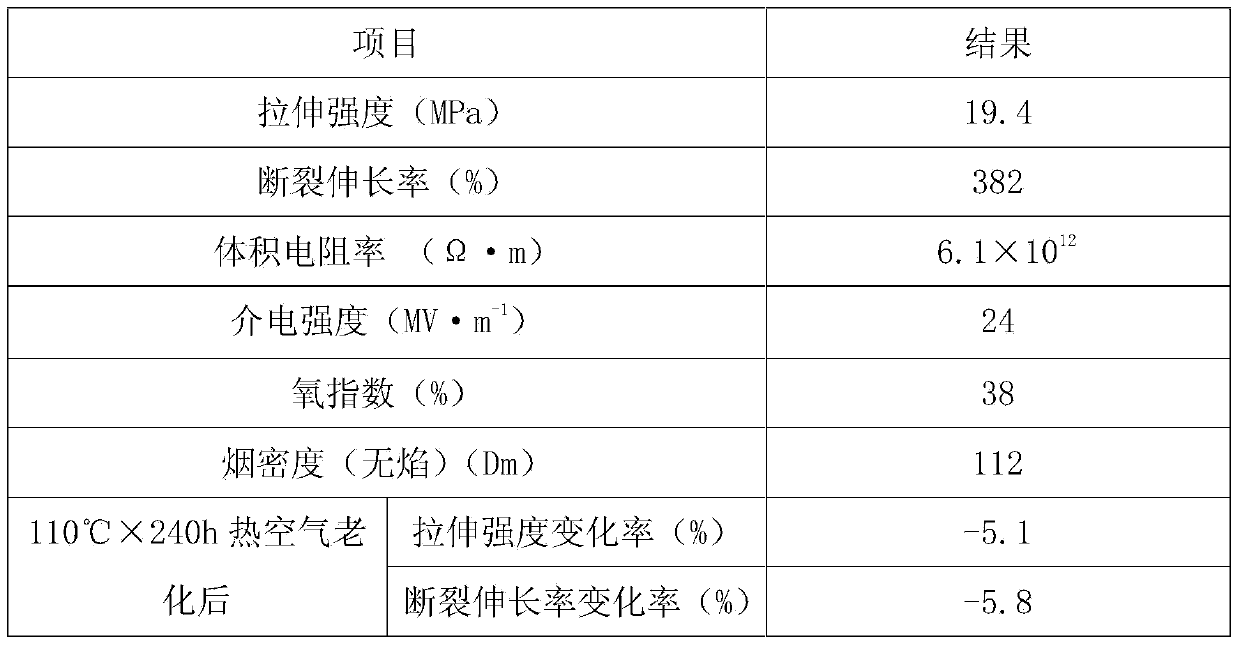

[0010] A high-toughness and high-impact polyvinyl chloride cable material, made of the following raw materials (kg): SG-3 type PVC resin 50, ABS resin 20, PPS resin 10, toughening agent HP40516, dibutyl sebacate Ester 8, dioctyl maleate 4, mica powder 6, antimony trioxide 8, activated calcium carbonate 12, carbon black N33918, composite filler 6, monoglyceride stearate 2, calcium zinc composite stabilizer 2, antimony Oxygen agent 10100.8, dicumyl peroxide 1.5 trimethylolpropane trimethacrylate 0.6;

[0011] The preparation method of described composite filler is as follows: a. get the raw material of following weight (kg): fluorite 12, dolomite 6, acrylic acid 12, jade powder 8, ammonium persulfate 0.1, urotropine 0.6, volcanic ash 4, hydrogen Aluminum oxide 6, barium sulfate whisker 4, calcium stearate 2, mullite 8, polytetrafluoroethylene micropowder 6, N-2-(aminoethyl)-3-aminopropyltrimethoxysilane 2; b 1. Calcinate fluorite and dolomite at 530°C for 4 hours, mix them with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com