Aqueous photocurable coating with ultra low VOC emission and preparation method thereof

A coating and water-based technology, which is applied in the field of water-based non-photoinitiator UV-cured coatings and its preparation, can solve the problems of low performance and pollution, and achieve the effects of impact resistance, good hydrophobicity and oleophobicity, and high flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

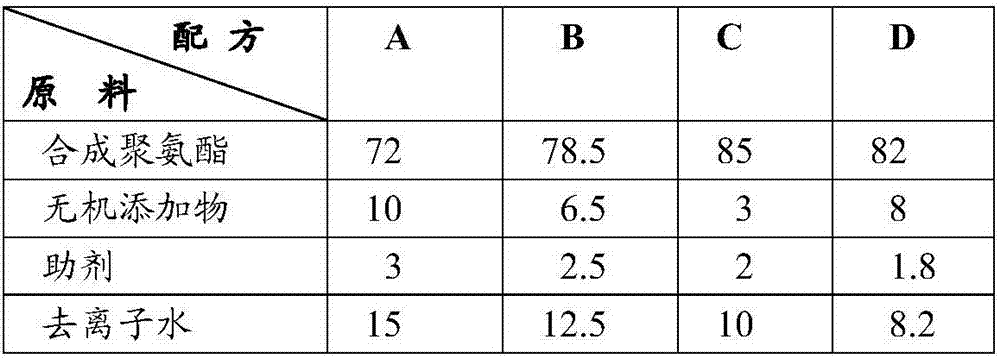

[0033] The coating of the present invention is applied to the screen glass of a mobile phone by a spraying process. Prepare the coating according to the ratio of the following raw materials:

[0034] Synthetic Polyurethane 78%, SiO 2 8%, dispersant 0.8%, wetting agent 0.6%; leveling agent (BYK-3455) 0.5%, anti-scratch agent (BYK-3600) 0.5%, slip agent (BYK-333) 0.5%, balance for deionized water.

[0035] The spraying process is: spraying (manual or automatic) (wet film thickness 25-30μm) - static leveling (heating 55-65 degrees Celsius) for 2-3 minutes - UV (365 nanometer wavelength, 100W / cm, 600J / cm 2 ) 10-20 seconds.

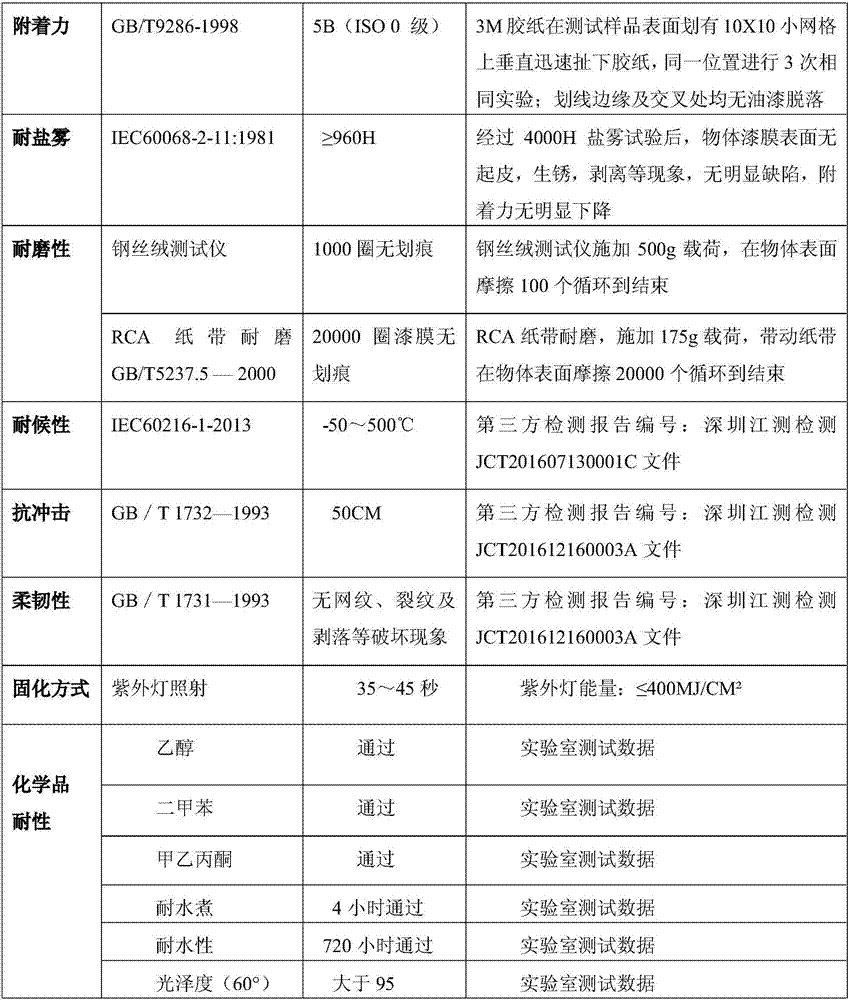

[0036] Performance:

[0037] This formula is mainly used to improve the surface stress and feel of the glass surface by combining the high hardness and flexibility of the coating;

[0038] This recipe prepares the product:

[0039] Surface pencil hardness: 9H; water vertical angle: 105; resistance to steel wool friction: 1kg weight 2000 times;

[0040]...

Embodiment 2

[0042] The paint of the present invention is applied to the panel of household appliances by using a spraying process. Prepare the coating according to the ratio of the following raw materials:

[0043] Synthetic Polyurethane 72%, SiO 2 5%, TiO 2 5%, dispersant 1.0%, wetting agent (BYK-349) 1.5%, leveling agent (BYK-3455) 0.5%, the rest is deionized water.

[0044] Application and performance indicators:

[0045] The formula mainly combines the high hardness, flexibility, and antibacterial properties of the coating, and is used to improve the anti-fouling and self-cleaning effects of the surface of household appliances (such as dishwashers and disinfection cupboards);

[0046] This recipe prepares the product:

[0047] Surface pencil hardness: 9H; water vertical angle: 105; RCA paper tape abrasion resistance test exceeds 10,000 scratches;

[0048] Due to the addition of nano-TiO to the paint 2 , making it have a very strong "super-hydrophilic property", making it diffi...

Embodiment 3

[0050] The coating of the present invention is applied to the surface of artificial stone for cabinets or the surface of 3D printed ceramic tiles by using a spraying process. Prepare the coating according to the ratio of the following raw materials:

[0051] Synthetic polyurethane 85% (this application type uses phenolic formaldehyde instead of viscosity modifier during the synthesis of coating polymers), SiO 2 3%, dispersant 0.8%, wetting agent (BYK-349) 0.7%, leveling agent (BYK-3455) 0.5%, the rest is deionized water.

[0052] Application and performance indicators:

[0053] Surface pencil hardness: 9H; water vertical angle: greater than 97; resistance to steel wool friction: 1kg weight 2500 times, resistance to high-heeled shoes friction and sand vibration friction;

[0054] This formula mainly combines the high transparency, high hardness, flame retardant and high temperature resistance properties of the coating, and self-cleaning properties to improve the defect of low...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pen hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com